High-Density Polyethylene (HDPE) duct couplers have become an essential component in modern infrastructure, particularly in telecommunications, electrical installations, and fiber optic cable protection. Their durability, flexibility, and resistance to harsh environmental conditions make them a preferred choice for connecting and securing HDPE ducts. Whether you are looking to learn about the HDPE duct coupler price, find reliable suppliers, or understand the installation process, this guide covers all the critical aspects you need to know.

What Are HDPE Duct Couplers?

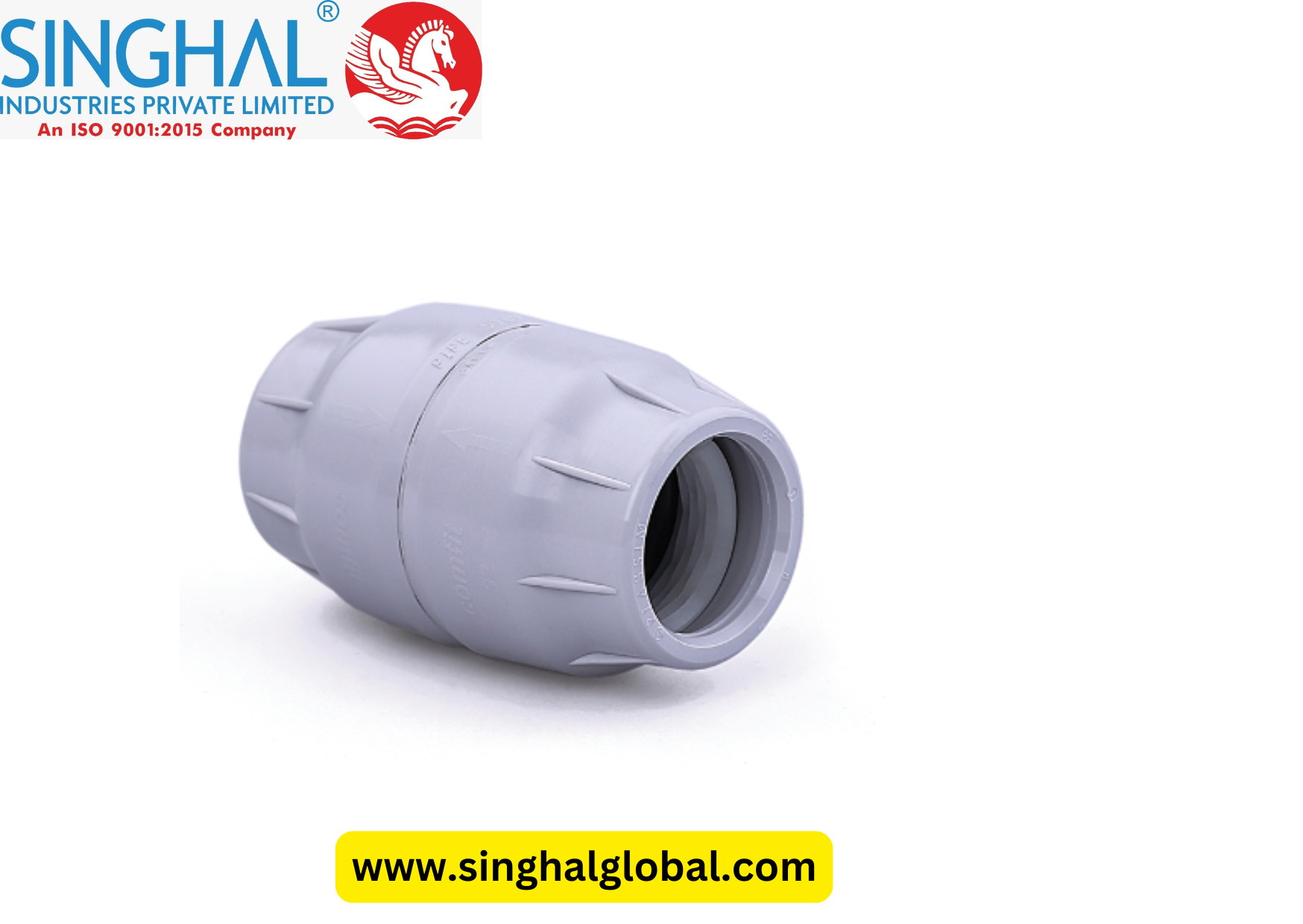

HDPE duct couplers are devices used to connect two HDPE ducts, creating a seamless passage for cables, fibers, or other utilities. These couplers are designed to provide a secure and airtight connection, ensuring that the integrity of the ducting system is maintained. They are commonly used in industries such as telecommunications, gas pipelines, water management, and electrical installations.

There are different types of HDPE duct couplers, including:

- Push-fit couplers: Easy to install without the need for tools.

- Compression couplers: Require compression tools for installation, providing a stronger connection.

- Heat-shrink couplers: Utilize heat to create a secure and watertight connection.

Key Advantages of HDPE Duct Couplers

HDPE duct couplers offer several advantages that make them ideal for a wide range of applications:

-

Durability: Made from high-density polyethylene, these couplers are highly resistant to physical damage, chemicals, and UV rays. This makes them perfect for outdoor installations and long-term use.

-

Flexibility: HDPE couplers are flexible enough to accommodate slight movements or shifts in the ground, especially in regions prone to seismic activity.

-

Lightweight: HDPE duct couplers are relatively lightweight compared to metal alternatives, which makes them easier to transport and install.

-

Corrosion-Resistant: Unlike metal duct connectors, HDPE duct couplers do not corrode, making them a more reliable and longer-lasting solution, particularly in moisture-rich environments.

-

Cost-Effective: While the HDPE duct coupler price can vary depending on the type, size, and supplier, these couplers generally provide excellent value for money, offering long-lasting performance at a competitive price.

Factors Affecting HDPE Duct Coupler Price

The HDPE duct coupler price can depend on several factors, including:

-

Material Quality: HDPE duct couplers made from higher-grade polyethylene tend to be more expensive due to their enhanced durability and performance.

-

Size: Larger couplers designed to fit bigger ducts will generally cost more than smaller ones.

-

Type of Coupler: Push-fit couplers are often more affordable, while compression and heat-shrink couplers, which require more specialized materials and installation processes, can be priced higher.

-

Supplier: The cost of an HDPE duct coupler can vary depending on the supplier. Local suppliers may offer lower prices due to reduced shipping costs, whereas international suppliers could have higher prices but offer a broader range of products.

-

Bulk Purchases: Purchasing in bulk often leads to discounts. Many suppliers offer tiered pricing where the cost per unit decreases as the quantity increases.

Finding a Reliable HDPE Duct Coupler Supplier

Choosing the right HDPE duct coupler supplier is crucial for ensuring product quality, timely delivery, and cost-effectiveness. Here are some tips for finding a reliable supplier:

-

Reputation and Experience: Look for suppliers with a strong track record and years of experience in the industry. A reputable supplier is more likely to provide high-quality products and reliable service.

-

Product Range: The best suppliers offer a variety of HDPE duct couplers in different sizes, types, and specifications. This allows you to choose the exact product that fits your needs.

-

Certifications and Standards: Make sure the supplier complies with industry standards and has the necessary certifications. This ensures that the products meet safety and quality requirements.

-

Customer Support: A good supplier should provide excellent customer support, answering your queries about the product, installation, and pricing.

-

Delivery Time and Logistics: Fast and efficient delivery is essential, especially for large-scale projects. Check if the supplier offers reliable shipping options and can deliver on time.

HDPE Duct Coupler Installation Process

Proper HDPE duct coupler installation is crucial for ensuring a secure and long-lasting connection. The installation method can vary depending on the type of coupler used. Below is a general overview of the installation process for the most common types of HDPE duct couplers:

-

Push-Fit Couplers:

- Preparation: Clean the ends of the HDPE ducts to ensure no debris is present.

- Insertion: Align the ends of the ducts and push them into the coupler until they are securely in place. Push-fit couplers are designed to grip the ducts, creating a tight seal.

- Sealing: Once inserted, the coupler will create an airtight and watertight seal, ensuring no external elements can penetrate the duct.

-

Compression Couplers:

- Preparation: Similar to push-fit couplers, clean the duct ends to ensure proper fitting.

- Fitting: Place the compression coupler onto the ends of the ducts.

- Compression: Using a compression tool, tighten the coupler until it securely clamps down on the ducts, creating a strong mechanical connection.

- Sealing: Ensure that all parts are aligned properly and that the coupler is sealed tight to prevent any leakage.

-

Heat-Shrink Couplers:

- Preparation: Clean and dry the ends of the ducts thoroughly.

- Fitting: Slide the heat-shrink coupler over the duct ends.

- Heat Application: Use a heat gun or torch to apply heat to the coupler. As the coupler shrinks, it forms a tight seal around the ducts.

- Sealing: Heat-shrink couplers are ideal for creating watertight and airtight connections. Ensure even heating to avoid weak spots.

Each of these methods has its advantages, and the choice of installation method often depends on the application, environment, and specific project requirements.

Conclusion

HDPE duct couplers are essential components in industries that rely on secure and durable ducting systems. Whether you are concerned about the HDPE duct coupler price, finding a trusted supplier, or ensuring proper installation, understanding the key aspects of these couplers can help you make informed decisions.

Choosing the right type of HDPE duct coupler and following the correct installation process ensures that your ducting system operates efficiently and lasts for many years. With advancements in material science and manufacturing techniques, HDPE duct couplers will continue to play a vital role in modern infrastructure, providing reliable and cost-effective solutions for various industries.

Here Are Three Related for HDPE duct coupler price

Q1. How much does an HDPE duct coupler typically cost?

Ans. The price of an HDPE duct coupler can vary based on factors like size, type, and quality, but generally ranges from a few dollars for smaller push-fit couplers to higher costs for compression or heat-shrink types.

Q2. How do I find a reliable HDPE duct coupler supplier?

Ans. Look for suppliers with a strong reputation, a wide product range, necessary certifications, and excellent customer support. Bulk purchasing from established suppliers can also lead to cost savings.

Q3. What is the best method for HDPE duct coupler installation?

Ans. The best installation method depends on the type of coupler. Push-fit couplers are easy to install, while compression and heat-shrink couplers offer stronger, more secure connections suitable for heavy-duty applications.