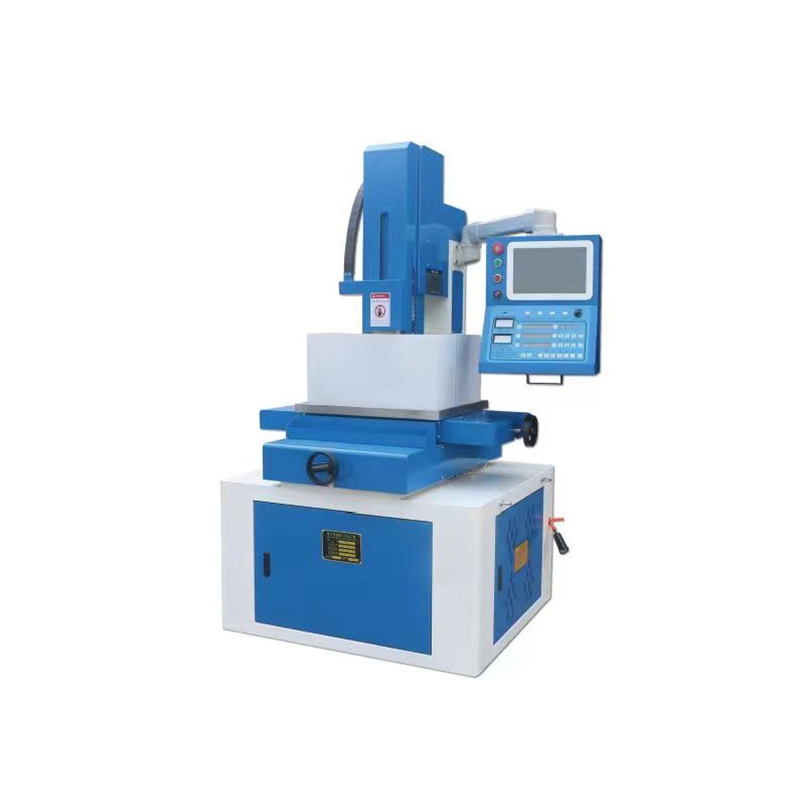

In today's competitive manufacturing landscape, optimizing every stage of the process is crucial for success. A multi-function precision punching machine can be a game-changer, streamlining operations, enhancing precision, and boosting overall efficiency. At Dingxing, our CKJ35 Multi-function Precision Punching Machine is engineered to deliver exceptional performance and versatility, helping you optimize your manufacturing process.

Understanding the Power of Multi-Function Precision Punching

Traditional punching machines are limited to performing a single function. Multi-function machines, however, integrate multiple capabilities into one unit, offering a range of operations in a single setup. This integration leads to reduced setup times, lower material handling costs, and improved accuracy.

The Principle Behind Precision Punching

The CKJ35 Multi-function Precision Punching Machine utilizes electrode tubes (brass or copper) as processing electrodes. These electrodes perform pulse spark discharges to erode metal and create precise holes in the workpiece. Unlike wire-cut EDM machines, our electric pulse electrode is a hollow copper rod, allowing the medium to pass through a fine hole in the middle for cooling and chip removal. The discharge between the electrode and the metal generates high-temperature corrosion to achieve the desired perforation.

Key Features and Advantages

1. Direct Penetration: Process directly from irregular shapes, such as inclined and curved surfaces.

2. Broken Tap Removal: Easily etch away broken drill bits and taps without damaging the original holes or threads.

3. Versatile Coolant Use: Use pure water or tap water as a processing coolant.

4. High Precision: Spindle lifting and XY axis movements use precision linear guides and ball screws for optimal accuracy.

5. Servo-Driven Spindle: Achieve rapid lifting with electrically controlled head stroke, thanks to the servo motor drive.

6. Robust Rotating Head: Maintain concentricity with a tungsten steel resistant sheet and multiple waterproof structures.

7. Large Work Envelope: The Z-axis stroke reaches 380mm, accommodating a 500mm long electrode, minimizing electrode tube waste.

8. High Depth-to-Diameter Ratio: Achieve a maximum processing depth-to-diameter ratio of 300:1.

9. High Punching Speed: Operate at speeds between 30-60mm/rpm.

10. Advanced High Frequency: Replace traditional analog high frequency with a digital system for more accurate control, PWM dedicated pulse output, eliminating code switch, more stable.

11. Smooth Surface Finish: Benefit from a high-frequency soft start function for a smooth processing surface with no burns or burrs.

Applications Across Industries

The CKJ35 Multi-function Precision Punching Machine is suitable for a wide range of applications:

Mold Manufacturing: Process small micro holes on molds with precision.

Textile Industry: Create threading holes and spinneret holes in chemical fiber spinnerets.

Filtration: Manufacture group holes of filter plates and sieve plates.

Aerospace: Produce heat dissipation holes in discharge motor blades and cylinders.

Hydraulics and Pneumatics: Fabricate oil and gas holes in valve bodies.

Tool Salvage: Remove broken drill bits and taps from workpieces without damage.

Optimizing Your Manufacturing Process

Investing in a CKJ35 Multi-function Precision Punching Machine can transform your manufacturing process:

Increased Efficiency: Perform multiple operations on a single machine, reducing setup times and material handling.

Enhanced Precision: Achieve tight tolerances and consistent results with advanced control systems and precision components.

Reduced Costs: Lower labor costs, minimize material waste, and improve overall productivity.

Greater Versatility: Handle a wider range of materials and complex designs with ease.

Improved Product Quality: Create high-quality components with smooth finishes and accurate dimensions.

Electrical Control System

The electrical system is composed of a pulse power supply, spindle servo system, rotating head device, and rectifier unit:

Pulse Power Supply: Manually selected parameters or database parameters allow the integrated circuit to generate precise pulses, controlling the processing current within the operator's set range.

Spindle Servo System: The system controls the spindle feed speed with precision based on the feedback from the signal processing unit.

Elevate Your Manufacturing with Dingxing

A Dingxing CKJ35 Multi-function Precision Punching Machine helps optimize manufacturing processes, delivering quality and efficiency. Contact us today to learn more about how our precision punching solutions can elevate your business.