Introduction

High-Density Polyethylene (HDPE) sheets, also known as high-density plastic sheets, are widely recognized for their durability, chemical resistance, and versatility. These sheets are used in various applications, ranging from construction and manufacturing to agriculture and packaging. With increasing demand for sustainable and reliable materials, HDPE sheets have emerged as a go-to solution for numerous industries. This article delves into the features and benefits of high density polyethylene sheets, highlighting their applications and addressing common questions.

What are HDPE Sheets?

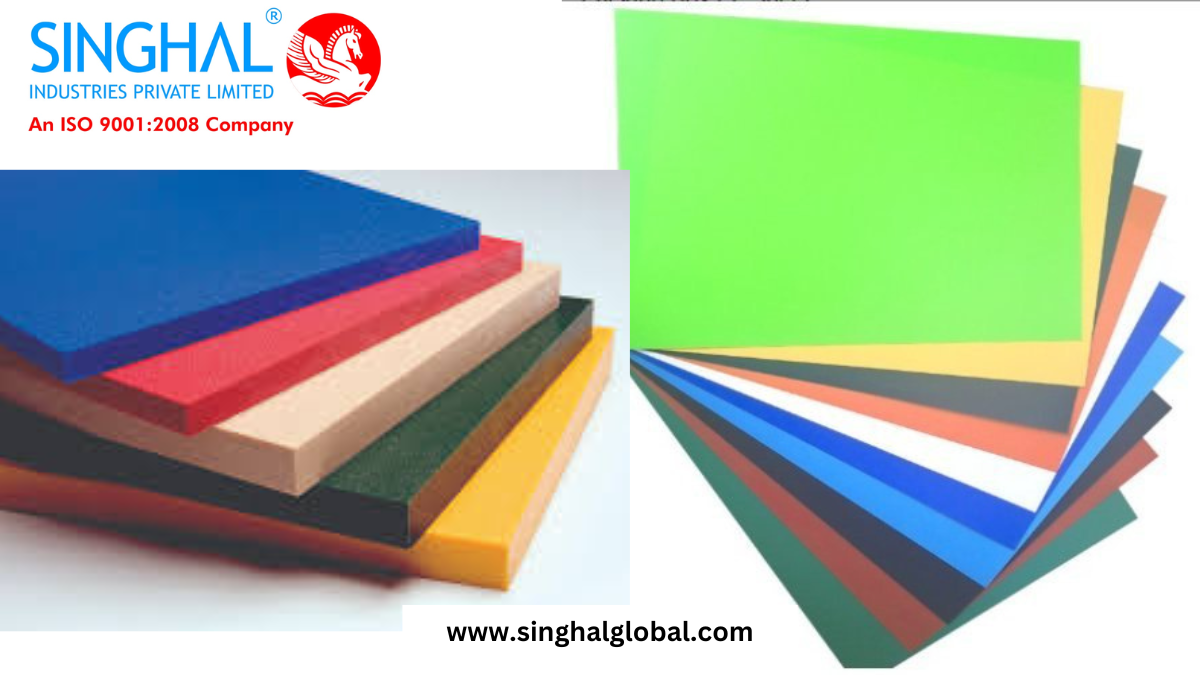

High density polyethylene sheets are manufactured from high-density polyethylene resin, a thermoplastic known for its strength and density. These sheets can be produced in various thicknesses and sizes, making them adaptable for multiple applications. The inherent properties of HDPE, such as resistance to impact, moisture, and chemicals, make these sheets ideal for both indoor and outdoor use.

Key Features of HDPE Sheets

-

Durability: HDPE sheets are exceptionally strong and can withstand harsh environmental conditions, making them suitable for long-term applications.

-

Chemical Resistance: One of the standout features of polyethylene high density sheets is their resistance to a wide range of chemicals, including acids, bases, and solvents. This property makes them ideal for use in industrial environments where exposure to harsh substances is common.

-

Low Moisture Absorption: Unlike other materials, HDPE sheets do not absorb moisture, making them resistant to mold and mildew. This characteristic is particularly beneficial for applications in humid environments.

-

Easy to Fabricate: High density plastic sheets can be easily cut, shaped, and welded, allowing for customization to meet specific project requirements.

-

Recyclability: HDPE is a recyclable material, contributing to environmentally friendly practices in various industries. Recycling HDPE sheets helps reduce waste and promotes sustainability.

Applications of HDPE Sheets

The versatility of High density polyethylene sheets allows them to be used in numerous industries and applications:

1. Construction and Building

In the construction sector, HDPE sheets are commonly used as liners for landfills, ponds, and water treatment facilities. Their chemical resistance and durability make them ideal for containment applications. Additionally, HDPE sheets can be used as moisture barriers, preventing water damage to structures.

2. Packaging

High density plastic sheets are extensively used in packaging applications. They can be found in various forms, including pallets, containers, and shrink wraps. The strength and lightweight nature of HDPE sheets make them a preferred choice for transporting goods safely.

3. Agriculture

In agriculture, HDPE sheets are used for greenhouse coverings, mulch films, and as protective liners for ponds and reservoirs. Their UV resistance helps extend the lifespan of agricultural installations, while their moisture barrier properties enhance crop protection.

4. Industrial Applications

HDPE sheets are widely used in industrial settings for creating safety guards, machine enclosures, and equipment panels. Their resistance to chemicals and ease of cleaning make them suitable for environments where hygiene is a priority.

5. Signage and Displays

The adaptability of high density polyethylene sheets also extends to the advertising and signage industries. These sheets can be easily printed on, making them ideal for creating durable outdoor signs that withstand the elements.

Choosing the Right HDPE Sheets

When selecting Polyethylene high density sheets for your project, consider the following factors:

1. Thickness and Size

HDPE sheets come in various thicknesses and sizes. Assess your project requirements to determine the appropriate dimensions and thickness for your application.

2. Finish

Consider whether you need a textured or smooth finish. Textured sheets can provide additional grip or aesthetic appeal, while smooth sheets are easier to clean and maintain.

3. Compliance and Standards

Ensure that the HDPE sheets you choose meet any relevant industry standards or regulations. This is especially important for applications in food packaging or medical environments.

Summary

In conclusion, high density polyethylene sheets are versatile materials with a wide array of applications across multiple industries. Their durability, chemical resistance, and recyclability make them a preferred choice for projects requiring reliable and sustainable solutions. Whether used in construction, packaging, agriculture, or industrial settings, polyethylene high density sheets continue to play a crucial role in modern manufacturing and infrastructure. As industries evolve and the demand for sustainable materials increases, the significance of HDPE sheets is poised to grow even further.

FAQs

1. What are the advantages of using HDPE sheets over other materials?

HDPE sheets offer several advantages, including exceptional durability, chemical resistance, low moisture absorption, and ease of fabrication. These properties make them suitable for a wide range of applications across various industries.

2. Can HDPE sheets be recycled?

Yes, high density polyethylene sheets are recyclable. Recycling helps reduce waste and supports environmentally friendly practices. Many manufacturers offer recycling programs for HDPE materials.

3. How do I cut and shape HDPE sheets?

HDPE sheets can be easily cut using standard tools such as saws or knives. For more intricate shapes, CNC machining or routing can be used. Always ensure proper safety precautions are taken when working with cutting tools.