In modern production lines, where time and accuracy dictate success, reliable equipment becomes the silent partner to every operation. Among the essentials that support seamless production, Air Shaft manufacturers play a crucial role by delivering components that enable fast, secure, and stable handling of rolled materials. One standout name in this space is cbbmachine, recognized for crafting air shaft systems that merge innovation with industrial strength.

The air shaft is an unsung hero in machinery used for printing, slitting, laminating, and rewinding. It allows for rapid and easy loading or unloading of rolls, using an inflatable mechanism that tightly grips the core. This simplicity results in faster job changes, improved alignment, and less wear on both the shaft and the roll material. For industries where production speed matters, this technology represents a serious efficiency upgrade.

Manufacturers focused on roll-based operations need solutions that combine flexibility and reliability. A well-designed air shaft minimizes downtime, reduces material waste, and increases operator safety. The need to manually tighten or release cores with mechanical tools is eliminated, allowing operators to quickly adjust without interrupting workflow. This is where expert Air Shaft manufacturers make all the difference—offering systems that are not only functional but refined through continuous engineering improvements.

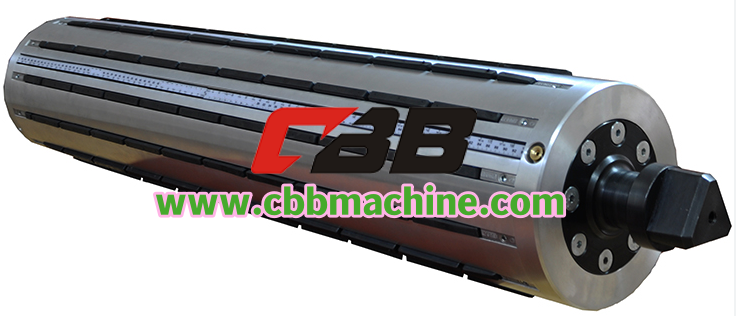

What separates cbbmachine from others in this segment is their commitment to user-centered design. Their air shafts are constructed from strong, lightweight materials like aluminum alloy or hardened steel, which makes them both sturdy and easy to handle. The internal bladder system is carefully calibrated to ensure even expansion, maintaining perfect grip across the entire core surface.

These shafts also excel in compatibility. Whether being integrated into new machines or retrofitted into existing lines, they are designed to fit different core sizes and machine specifications. This level of adaptability allows businesses to keep their investments efficient and scalable, adjusting components as production demands evolve.

Another point of distinction lies in maintenance. The best air shaft systems are those that can serve for years with minimal repair needs. cbbmachine pays close attention to how each part interacts and wears over time, ensuring that every component—from the valve to the air bladder—is built to withstand daily industrial use.

In today's global market, where consistency and precision are paramount, equipment that reduces error and supports productivity is indispensable. Air shaft technology supports this goal by improving the control over roll tension and positioning. Especially in high-speed operations, even the smallest imbalance can affect the final product. With air shafts in place, those risks are significantly minimized.

Choosing the right partner among Air Shaft manufacturers is key to unlocking these benefits. Companies that prioritize engineering integrity, customization, and long-term service offer far more than just components—they offer a competitive edge. cbbmachine stands among these, delivering products that align with real-world manufacturing challenges and goals.

Whether you're scaling up an operation or fine-tuning an existing line, implementing the right air shaft system can dramatically improve how your business functions day to day. It's not just about movement—it's about control, consistency, and confidence in every production run.

Welcome to visit our website: www.cbbmachine.com