The automotive industry demands materials that not only offer strength and durability but also provide aesthetic appeal and protection against corrosion. GI prepainted galvanized steel coils have emerged as a popular choice for automotive applications, thanks to their exceptional properties and versatility. In this blog post, we will explore the common applications of GI prepainted galvanized steel coils in the automotive industry, highlighting their advantages and contributions to the manufacturing of high-quality vehicles.

The Advantages of Using GI Prepainted Galvanized Steel Coils

GI Prepainted Galvanized Steel Coils offer a range of advantages that make them an ideal choice for various applications, including the automotive industry. One of the key benefits is their exceptional corrosion resistance. The galvanized coating on these steel coils acts as a protective barrier against moisture and other environmental factors, ensuring long-lasting durability for automotive components.

Another advantage is their excellent paint adhesion properties. The pre-painted surface of these coils provides a smooth and uniform base for applying coatings, resulting in a high-quality finish that enhances the aesthetic appeal of vehicles. This not only improves the overall appearance but also helps to maintain the value of automobiles.

Furthermore, GI Prepainted Galvanized Steel Coils are lightweight yet strong, making them suitable for manufacturing parts that require both structural integrity and reduced weight. This contributes to fuel efficiency and better overall performance while maintaining safety standards.

Additionally, these steel coils are highly versatile and can be easily formed into different shapes and sizes during production. This flexibility allows manufacturers in the automotive industry to create complex designs with precision while minimizing material waste.

Moreover, GI Prepainted Galvanized Steel Coils are environmentally friendly due to their recyclability. By using these coated coils in automobile manufacturing processes, it promotes sustainability by reducing resource consumption and minimizing waste generation.

The advantages offered by GI Prepainted Galvanized Steel Coils make them an indispensable material in the automotive industry. Their corrosion resistance, excellent paint adhesion properties, strength-to-weight ratio, versatility in shaping capabilities,and recyclability all contribute to enhancing vehicle performance and aesthetics while being eco-friendly at the same time.

Common Applications of GI Prepainted Galvanized Steel Coils in the Automotive Industry

The automotive industry is constantly evolving, and with it, the materials used in car manufacturing. One such material that has gained popularity in recent years is GI prepainted galvanized steel coils. These coils offer a range of benefits that make them ideal for various applications within the automotive sector.

One common application of GI prepainted galvanized steel coils in the automotive industry is in the production of car bodies. The high strength and durability of these coils make them perfect for forming panels that can withstand harsh conditions on the road. Additionally, the painted surface provides an attractive finish that enhances the overall aesthetic appeal of the vehicle.

Another area where these coils are utilized is in the manufacturing of car parts such as fenders, doors, and hoods. Their corrosion resistance properties ensure longevity even when exposed to moisture and other environmental factors. This not only improves the lifespan of these components but also reduces maintenance costs for car owners.

Furthermore, GI prepainted galvanized steel coils are commonly used in producing chassis and frames for automobiles. The lightweight nature combined with their ability to maintain structural integrity makes them an excellent choice for this purpose. This ultimately results in vehicles that are both fuel-efficient and safe.

In addition to these applications, GI prepainted galvanized steel coils find use in various interior components like seat frames and dashboard structures due to their strength-to-weight ratio and versatility.

There are numerous ways GI prepainted galvanized steel coils contribute to advancements within the automotive industry – from enhancing aesthetics to improving performance and durability. As technology continues to progress, we can expect further innovations utilizing this versatile material across different areas of automobile manufacturing.

How GI Prepainted Galvanized Steel Coils are Used in Car Manufacturing

Car manufacturing is a complex process that requires the use of high-quality materials. One such

material that plays a crucial role in car production is GI prepainted galvanized steel coils. These coils are used in various aspects of car manufacturing, providing several benefits.

One common application of GI prepainted galvanized steel coils in car manufacturing is for the production of body panels. These coils are used to create durable and corrosion-resistant outer body parts like doors, hoods, and fenders. By using these coated steel coils, manufacturers can ensure that the cars they produce have strong and long-lasting exteriors.

In addition to body panels, GI prepainted galvanized steel coils are also utilized in the production of automotive frames and chassis components. The strength and durability provided by these coated steel coils make them ideal for constructing the structural framework of vehicles. This ensures that cars have a sturdy foundation while maintaining lightness for improved fuel efficiency.

Furthermore, these coated steel coils find applications in other areas within car manufacturing as well. They are often used for producing interior components like seat frames, dashboard structures, and door reinforcements. The versatility offered by GI prepainted galvanized steel allows manufacturers to utilize it throughout different stages of vehicle assembly.

GI prepainted galvanized steel coils play an integral role in the automotive industry due to their many advantages. Their ability to provide strength, durability, corrosion resistance makes them essential for creating reliable cars with long lifespans. With their widespread applications across different aspects of car manufacturing – from body panels to interior components – these coated steel coils continue to be a staple material in this thriving industry.

Conclusion

GI color-coated galvanized steel coils have become an indispensable material for the automotive industry. Its superior quality makes it ideal for a variety of applications, from body panels to interior components. The advantages they offer, such as durability, corrosion resistance and design versatility, make them the first choice for car manufacturers.

The use of GI pre-coated galvanized steel coils in automotive manufacturing helps improve the overall performance and longevity of the vehicle. These coils are widely used on components such as roofs, hoods, doors, and fenders as they are able to withstand harsh weather conditions and provide excellent protection against rust.

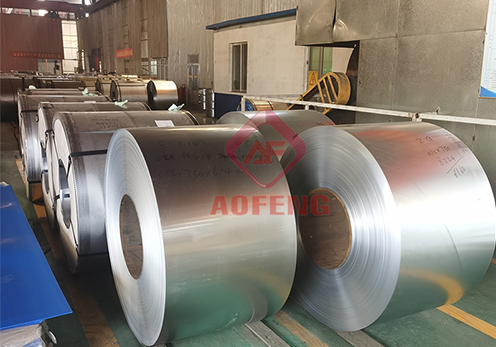

Shandong Aofeng Metal Material CO., LTD.was established in 2011, located in Liaocheng-one of the biggest cold rolled stainless steel production bases. Aofeng is specializing in processing cold rolle stainless steel coils and sheets.

Welcome to contact us,if you are interested in our products.

Email:[email protected]