Pharmaceutical manufacturing requires strict adherence to quality control measures to ensure the safety and efficacy of the products. One critical factor that can significantly impact the quality of pharmaceuticals is humidity. Humidity meters play a crucial role in monitoring and controlling humidity levels throughout the manufacturing process, ultimately contributing to the overall product quality.

The Importance of Humidity Control in Pharmaceutical Manufacturing

Humidity control is vital in pharmaceutical manufacturing as it directly affects the stability and integrity of the products. Fluctuations in humidity levels can lead to chemical degradation, physical changes, and microbial growth in pharmaceuticals, compromising their quality and safety. Therefore, maintaining optimal humidity conditions is essential to ensure the efficacy and shelf-life of pharmaceutical products.

Monitoring and Controlling Humidity Levels

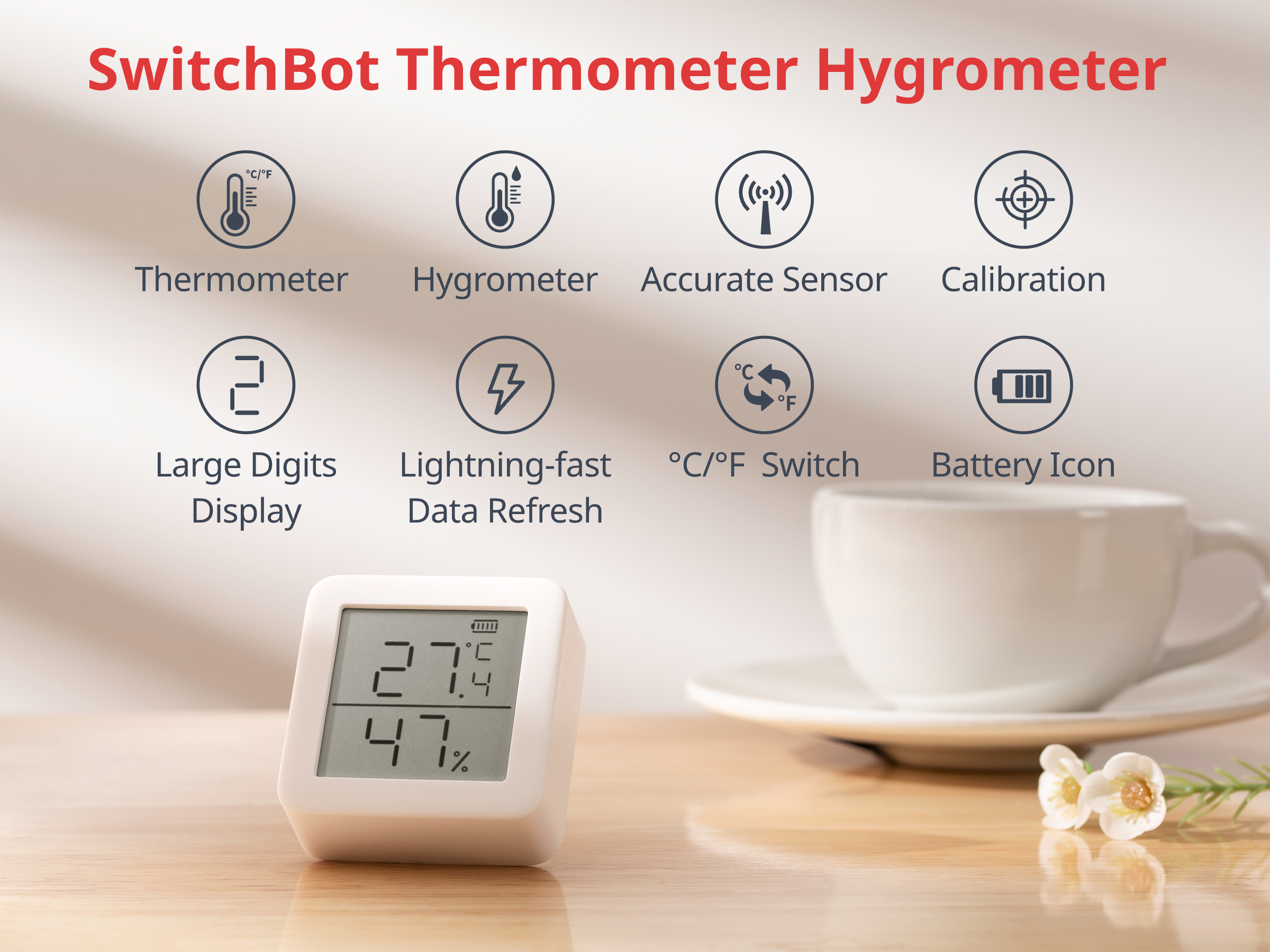

Humidity meters, also known as hygrometers, are used to measure the moisture content in the air and provide real-time data on humidity levels within manufacturing facilities. By continuously monitoring humidity, pharmaceutical companies can identify and address any deviations from the specified range promptly. Additionally, advanced humidity meters are equipped with control capabilities, allowing for automated adjustments to maintain optimal conditions.

Impact on Product Quality and Compliance

Consistent monitoring and control of humidity levels using specialized meters directly contribute to the overall quality and compliance of pharmaceutical manufacturing. By ensuring stable and suitable humidity conditions, pharmaceutical companies can minimize the risk of product degradation, contamination, and variability. This, in turn, leads to the production of high-quality pharmaceuticals that meet regulatory standards and provide reliable therapeutic outcomes for patients.

Enhancing Efficiency and Cost-Effectiveness

Humidity meters not only play a crucial role in maintaining product quality but also contribute to the efficiency and cost-effectiveness of pharmaceutical manufacturing. By preventing humidity-related issues, such as the need for reprocessing or discarding compromised products, companies can reduce waste and improve overall operational efficiency. Moreover, the implementation of precise humidity control can lead to energy savings and extended equipment lifespan, further optimizing manufacturing processes.

In conclusion, humidity meters are indispensable tools in pharmaceutical manufacturing, supporting the maintenance of optimal humidity levels to ensure product quality, regulatory compliance, and operational efficiency. By investing in advanced humidity monitoring and control systems, pharmaceutical companies can uphold their commitment to delivering safe and effective medications to patients worldwide.