Mirror stainless steel pipes have become increasingly popular in architectural, design, and industrial applications due to their exceptional aesthetic appeal and durability. The brightness and reflective properties of these pipes give them a distinct allure that enhances any setting they are used in. In this article, we will explore the characteristics and manufacturing process behind mirror stainless steel pipes, their various applications, and maintenance tips to ensure lasting brilliance.

Understanding Mirror Stainless Steel Pipes

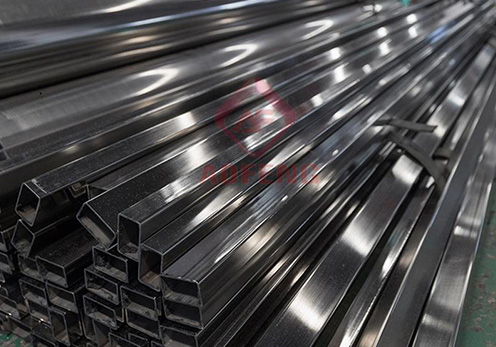

Mirror stainless steel pipes, also known as mirror polished pipes or mirror finish pipes, are created using a unique manufacturing process. These pipes undergo a series of polishing operations, resulting in a smooth, shiny, and highly reflective surface. The mirror-like finish is achieved by progressively grinding and buffing the stainless steel surface using abrasive materials and polishing compounds. This meticulous process removes imperfections and creates a flawless reflection.

Characteristics of Mirror Stainless Steel Pipes

1. Exceptional Brightness: Mirror stainless steel pipes boast a high level of brightness due to their superior reflective properties. They can reflect up to 95% of light, creating a stunning effect in any environment.

2. Durability: As with all stainless steel products, mirror stainless steel pipes are corrosion-resistant, ensuring longevity and minimal maintenance requirements.

3. Hygiene and Cleanliness: These pipes are easy to clean, making them ideal for use in industries such as food processing, pharmaceuticals, and healthcare. Their smooth surface prevents the accumulation of dirt, bacteria, and germs.

4. Aesthetic Appeal: Mirror stainless steel pipes add an elegant and modern touch to any space, making them favored by architects and interior designers for both commercial and residential projects.

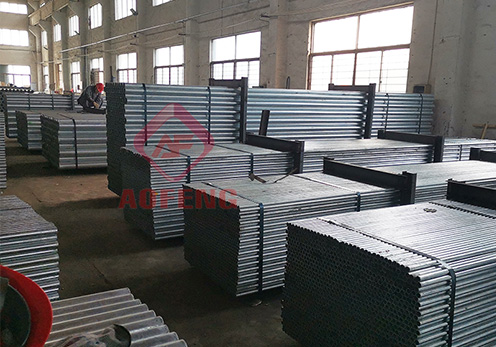

5. Versatility: These pipes come in various shapes and sizes, allowing for versatile application possibilities, from handrails and furniture to decorative accents and exhaust systems.

Applications of Mirror Stainless Steel Pipes

1. Architectural and Design Elements: Mirror stainless steel pipes can be used for decorative purposes, including handrails, balustrades, columns, and ornamental features in buildings. Their reflective surface adds depth and sophistication to architectural designs.

2. Furniture and Interior Design: The sleek and polished appearance of mirror stainless steel pipes makes them a favorite choice for furniture designers. They can be incorporated into tables, chairs, frames, and other interior elements to create a modern and stylish aesthetic.

3. Automotive Industry: Mirror stainless steel pipes find applications in the automotive industry, especially in the exhaust systems. The pipes' durable and corrosion-resistant properties make them an excellent choice for this demanding application.

4. Industrial Use: These pipes are widely used in the pharmaceutical, chemical, and food processing industries due to their cleanliness and hygiene benefits. They are often employed in the construction of pipelines, tanks, and other equipment.

Maintaining the Brightness of Mirror Stainless Steel Pipes

To ensure that mirror stainless steel pipes retain their brightness and luster over time, regular maintenance is essential. Here are a few tips to keep them looking their best:

1. Cleaning: Regularly clean mirror stainless steel pipes using a mild detergent and warm water. Avoid using abrasive cleaners, bleach, or chlorine-based products as they may damage the surface.

2. Soft Cloth: Use a soft cloth, microfiber towel, or non-abrasive sponge to wipe the surface gently. Avoid using rough brushes or scrubbing pads that may scratch or dull the shine.

3. Routine Inspection: Regularly inspect the pipes for any signs of damage, such as scratches or dents. Promptly address any issues to prevent further deterioration.

4. Protective Coatings: Consider applying a protective coating to the pipes to enhance their longevity and resistance to stains, fingerprints, and environmental elements.

5. Avoid Harsh Chemicals: Avoid using harsh chemicals or abrasive materials near mirror stainless steel pipes, as they can cause discoloration or corrosion.

Conclusion

Mirrored stainless steel pipes demonstrate the aesthetic and functional possibilities of stainless steel. Its exceptional brightness, durability and versatility make it an attractive choice for a variety of applications. Whether used in architectural design, interior decoration, automotive industry or industrial environments, mirrored stainless steel pipes add an elegant and modern touch.

The manufacturing process of mirror stainless steel pipes is extensive and involves multiple polishing operations to obtain a flawless reflective surface. The resulting high brightness allows these tubes to reflect up to 95% of light, creating a stunning visual effect. Additionally, their corrosion-resistant properties ensure longevity and minimal maintenance requirements.

To maintain the brightness and luster of mirror stainless steel pipes, regular maintenance is essential. It is recommended to clean them regularly using mild detergent and warm water. It is important to avoid using abrasive cleaners, bleach or chlorine-based products as they can damage the surface. Instead, choose a soft cloth, microfiber towel, or non-abrasive sponge to gently wipe down your pipes. Harsh chemicals and abrasive materials should also be avoided to prevent discoloration or corrosion.

In conclusion, mirrored stainless steel pipes are not only functional but also add a touch of brilliance to any environment. Their exceptional brightness, durability and versatility make them a popular choice in the construction, design and industrial sectors. By understanding its properties and following proper maintenance techniques, you can enjoy the long-lasting beauty and reflective properties of mirrored stainless steel pipe.