At AE Tooling, we understand that the right tooling is essential for maximizing the performance and efficiency of your press brake. That's why we offer high-quality Bystronic punches designed to deliver precision, durability, and consistent results. Whether you're bending simple shapes or complex geometries, our Bystronic punches will help you achieve optimal performance and productivity. This blog will explore the benefits of using our Bystronic punches and how they can enhance your bending operations.

The Importance of Quality Punches

The punch is a critical component of the press brake, directly impacting the accuracy and quality of the bend. High-quality punches ensure consistent bending angles, minimize material deformation, and reduce the need for rework. Investing in quality punches is an investment in the overall performance of your press brake and the quality of your finished parts.

Key Features of AE Tooling’s Bystronic Punches

High-Quality Materials

Crafted from C45 tempered material, our Bystronic punches are built to withstand the rigors of continuous use. This high-strength steel ensures durability and longevity, providing a reliable solution for your bending needs.

Precise Angle and Radius

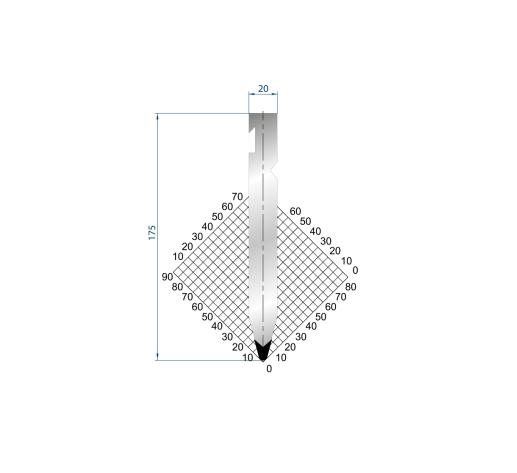

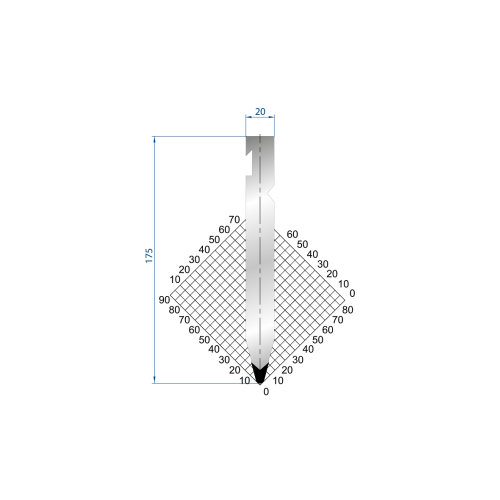

The 1231 - RF Punches - A 30° features a precise 30° angle and a 3mm radius, allowing for accurate and consistent bends. This precision ensures that each bend is perfectly formed, resulting in a clean and professional finish.

Versatile Length Options

We offer the 1231 RF Punch in multiple lengths, including 100 mm, 500 mm, 1000 mm, and 1100 mm Fraz., providing flexibility to accommodate various workpiece sizes. This versatility makes our punches suitable for a wide range of applications.

Optimized Dimensions

With a height of 175 mm, the 1231 RF Punch is designed to fit seamlessly into your existing setup. Its optimized dimensions ensure it doesn't take up excessive space while delivering exceptional performance.

Benefits of Using Bystronic Punches

Enhanced Accuracy

Bystronic punches ensure precise and consistent bends, reducing the risk of errors and rework. This leads to higher quality finished products and increased customer satisfaction. Bystronic punches are compatible with Bystronic-Beyeler RFA and other press brakes.

Increased Efficiency

Our punches are designed for easy integration and tool changes, minimizing downtime and maximizing productivity. High-performance punching tools can increase production speed.

Reduced Material Waste

With precise bending, you can minimize material waste, saving on costs and promoting sustainable manufacturing practices. Active hydraulic crowning improves bending accuracy.

Extended Tool Life

The high-quality materials and robust construction of our punches ensure long-lasting performance, reducing the need for frequent replacements and minimizing downtime. All press brake tooling produced by AE are deep hardened, enhancing the hardness of the steel and making them robust and durable.

Compatibility

Bystronic punches are designed for easy integration and tool changes, minimizing downtime and maximizing productivity. Our punches are compatible with Bystronic-Beyeler RFA and other press brakes.

Choosing the Right Punch

Selecting the right punch for your specific application is crucial for achieving optimal performance. Consider the following factors when making your selection:

Material Type: Different materials require different punch geometries and materials.

Bending Angle: Choose a punch with the appropriate angle for your desired bend.

Material Thickness: Ensure the punch is suitable for the thickness of the material you are bending.

Press Brake Compatibility: Verify that the punch is compatible with your press brake model.

Conclusion

Investing in Bystronic punches from AE Tooling is a smart decision for any sheet metal fabrication business looking to enhance efficiency, improve accuracy, and reduce costs. Our 1231 - RF Punches - A 30° exemplifies our commitment to providing high-quality, reliable tooling solutions. Explore our range of Bystronic punches and experience the difference in your bending operations. If you have any questions about our products or need assistance in selecting the right RF connector for your needs, feel free to reach out!