The growing demand for electric vehicles (EVs) and hybrid electric vehicles (HEVs) has increased the need for high-performance electric motors. The stator, a crucial component of these motors, plays a vital role in converting electrical energy into mechanical energy. High-quality new energy motor stators offer numerous benefits, including improved efficiency, increased power density, and enhanced reliability. This blog post explores the key features and benefits of high-quality new energy motor stators, with a focus on the solutions offered by Longnai Intelligent Co. Ltd.

Understanding the Stator's Role in New Energy Motors

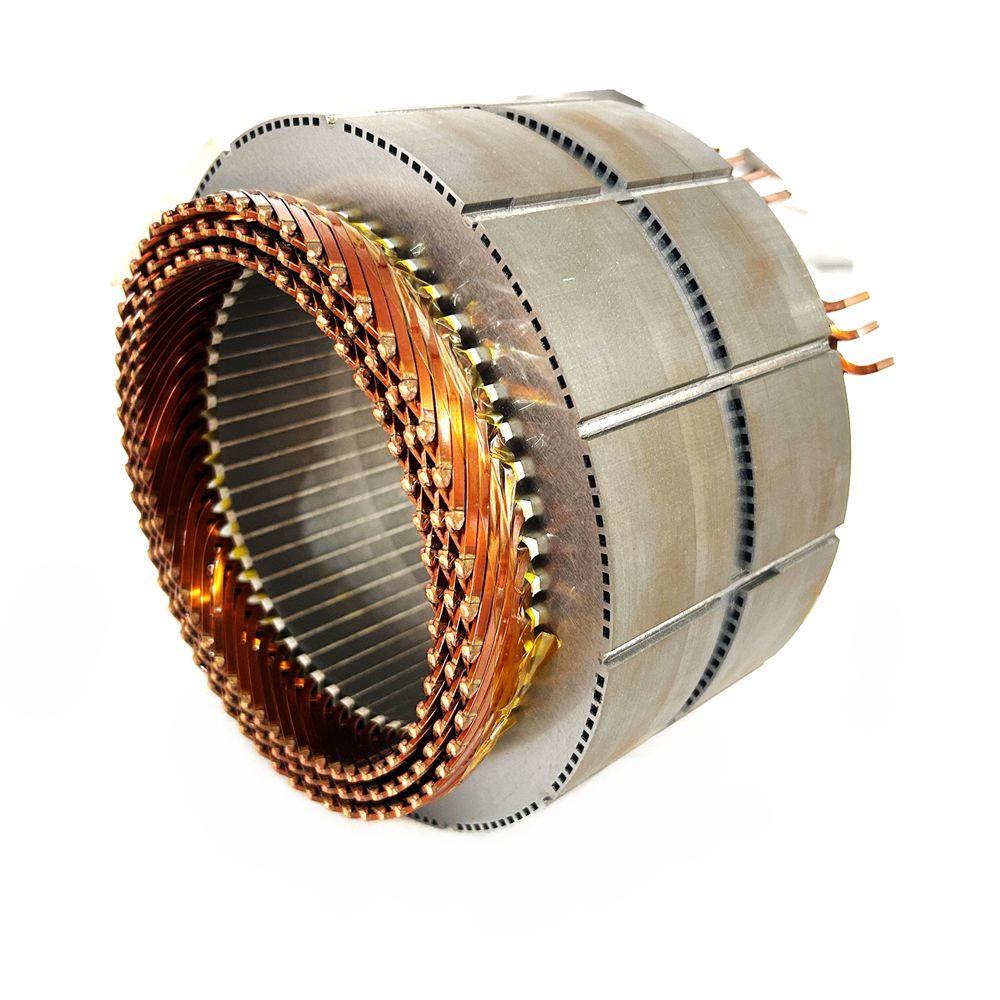

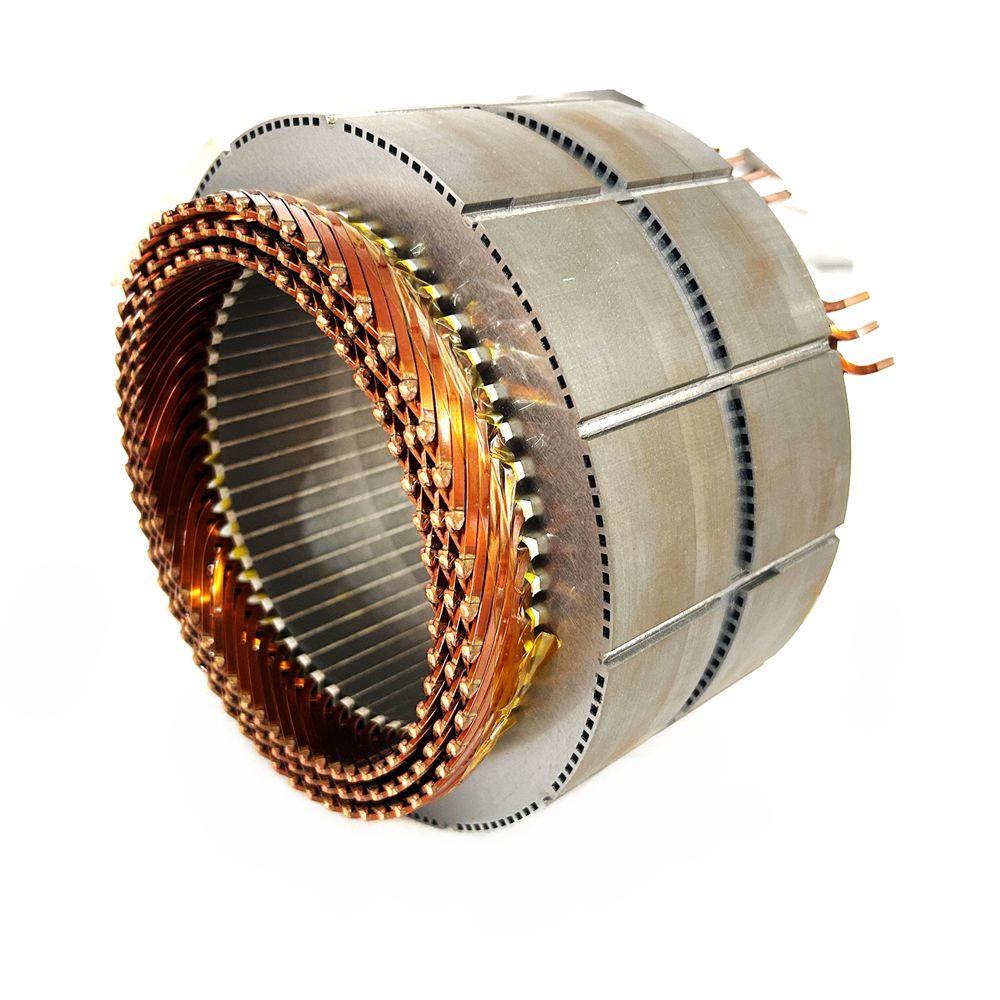

The stator is the stationary part of an electric motor, containing the windings that generate a magnetic field when energized. This magnetic field interacts with the rotor, the rotating part of the motor, producing torque and driving the vehicle. In new energy vehicles, stators must meet stringent requirements for efficiency, power density, and durability to maximize vehicle range and performance.

Key Features of High-Quality New Energy Motor Stators

High-Performance Materials: High-quality stators utilize advanced materials such as silicon steel laminations with high permeability and low core loss. These materials minimize energy waste due to hysteresis and eddy current losses, improving overall motor efficiency.

Optimized Winding Design: The winding configuration significantly impacts the stator's performance. High-quality stators employ optimized winding designs to maximize the magnetic field strength and minimize copper losses. Common winding techniques include distributed windings and concentrated windings, each offering unique advantages depending on the motor's specific requirements.

Precise Manufacturing Processes: The manufacturing process plays a critical role in ensuring the quality and performance of the stator. High-precision stamping, winding, and insulation techniques are essential to achieve tight tolerances and consistent performance. Automated manufacturing lines, like the Hairpin Motor Stator Production Line, ensure high levels of accuracy and repeatability.

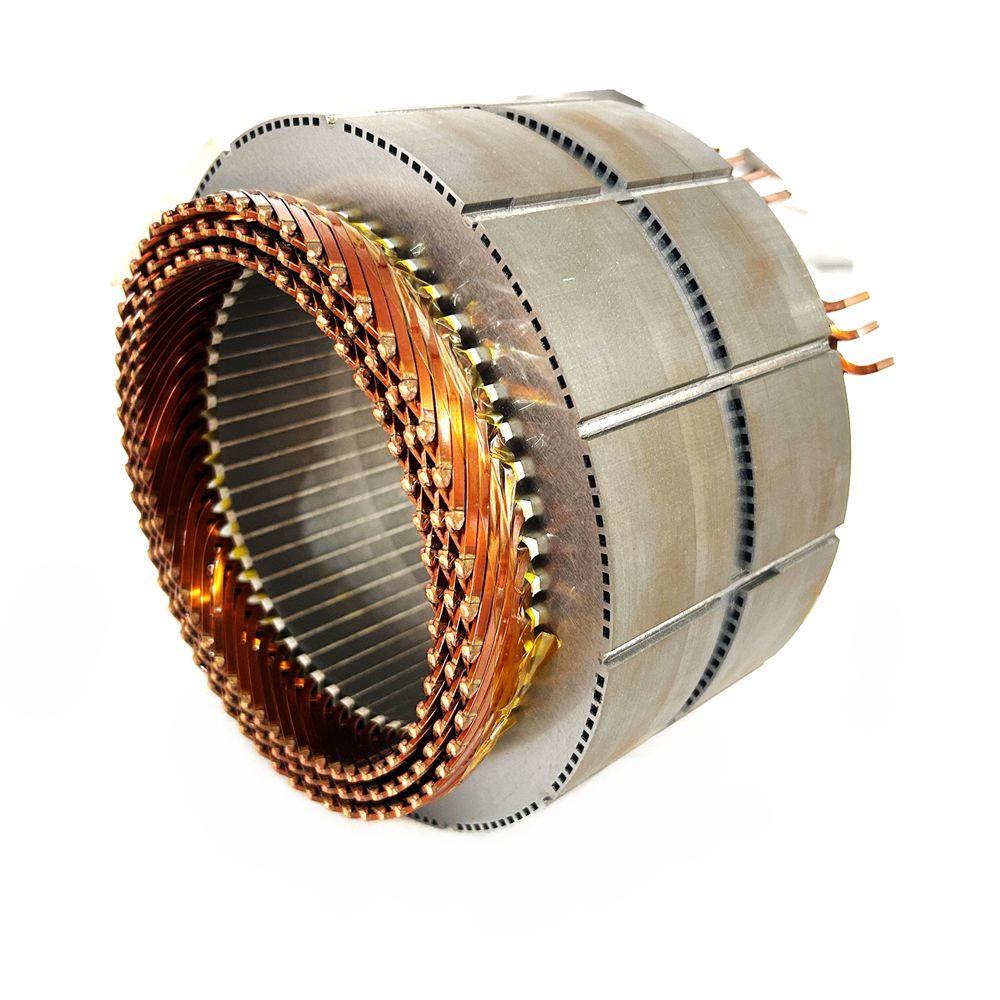

Effective Cooling Systems: Electric motors generate heat during operation, which can degrade performance and shorten lifespan. High-quality stators incorporate effective cooling systems, such as water jackets or air cooling channels, to dissipate heat and maintain optimal operating temperatures.

Robust Insulation: The insulation system is crucial for preventing electrical shorts and ensuring the stator's long-term reliability. High-quality stators use advanced insulation materials and processes to provide superior electrical insulation and thermal conductivity.

Benefits of Using High-Quality New Energy Motor Stators

Improved Energy Efficiency: High-quality stators minimize energy losses, resulting in improved motor efficiency and increased vehicle range.

Increased Power Density: Optimized designs and advanced materials enable high-quality stators to deliver more power in a smaller package, increasing the vehicle's power-to-weight ratio.

Enhanced Reliability and Durability: Robust materials, precise manufacturing, and effective cooling systems contribute to the enhanced reliability and durability of high-quality stators, ensuring long-term performance in demanding automotive applications.

Reduced Noise and Vibration: High-quality stators are designed to minimize noise and vibration, enhancing the overall driving experience.

Better Thermal Management: Effective cooling systems prevent overheating, maintaining optimal operating temperatures and prolonging the motor's lifespan.

Longnai Intelligent Co. Ltd: A Leader in Stator Technology

Longnai Intelligent Co. Ltd. is a China-based company specializing in the R&D and manufacturing of high-quality motor stators for new energy vehicles. With a focus on innovation and quality, Longnai offers a comprehensive range of stator solutions designed to meet the demanding requirements of the EV and HEV markets.

Customization and Expertise: Longnai provides customized stator designs and manufacturing services to meet the specific needs of its customers. Their team of experienced engineers works closely with clients to develop optimized solutions for various motor applications.

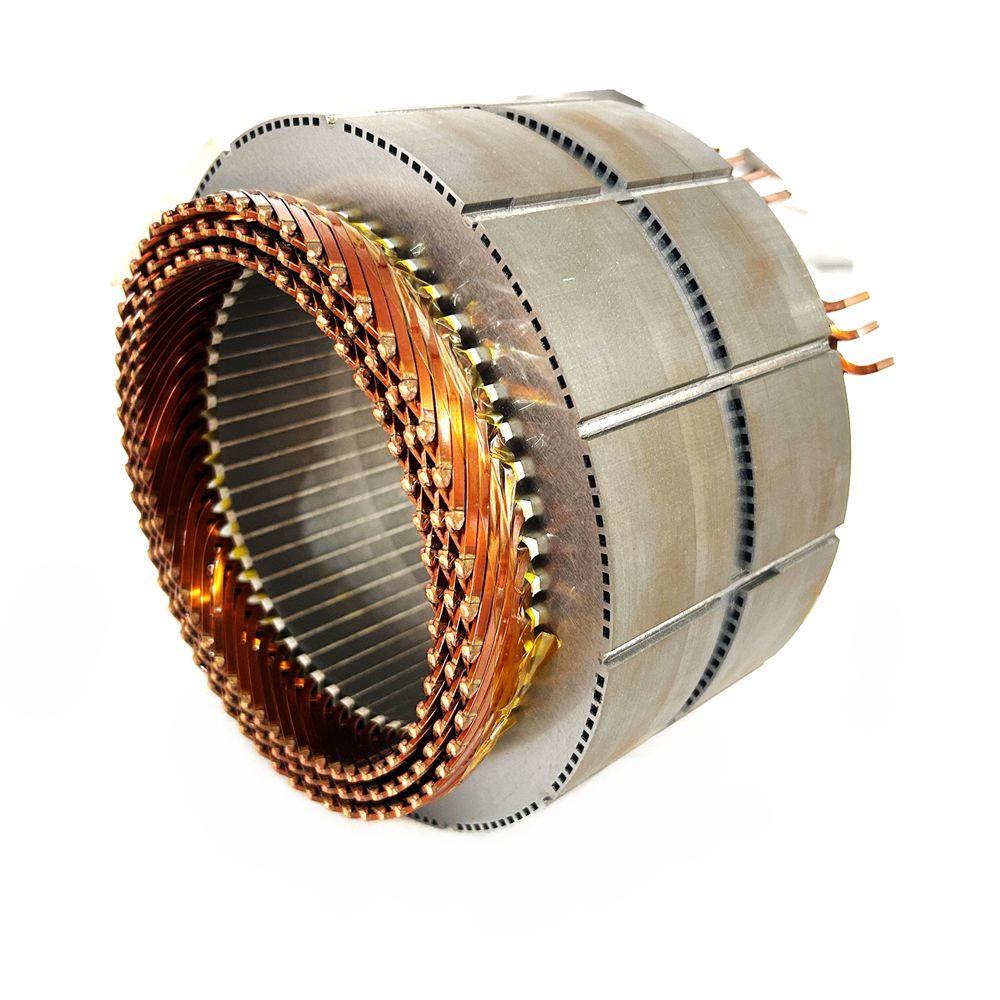

Advanced Manufacturing Capabilities: Longnai utilizes advanced manufacturing equipment and processes to ensure the highest levels of quality and precision. Their capabilities include high-speed stamping, automated winding, and advanced insulation techniques.

Quality Assurance: Longnai is committed to delivering high-quality products that meet or exceed industry standards. They implement rigorous quality control procedures throughout the manufacturing process to ensure consistent performance and reliability.

Longnai's Stator Solutions

Longnai offers a variety of stator solutions for new energy vehicles, including:

Stator Cores: Longnai manufactures high-quality stator cores using advanced materials and precision stamping techniques. Their stator cores are designed to minimize core losses and maximize magnetic field strength.

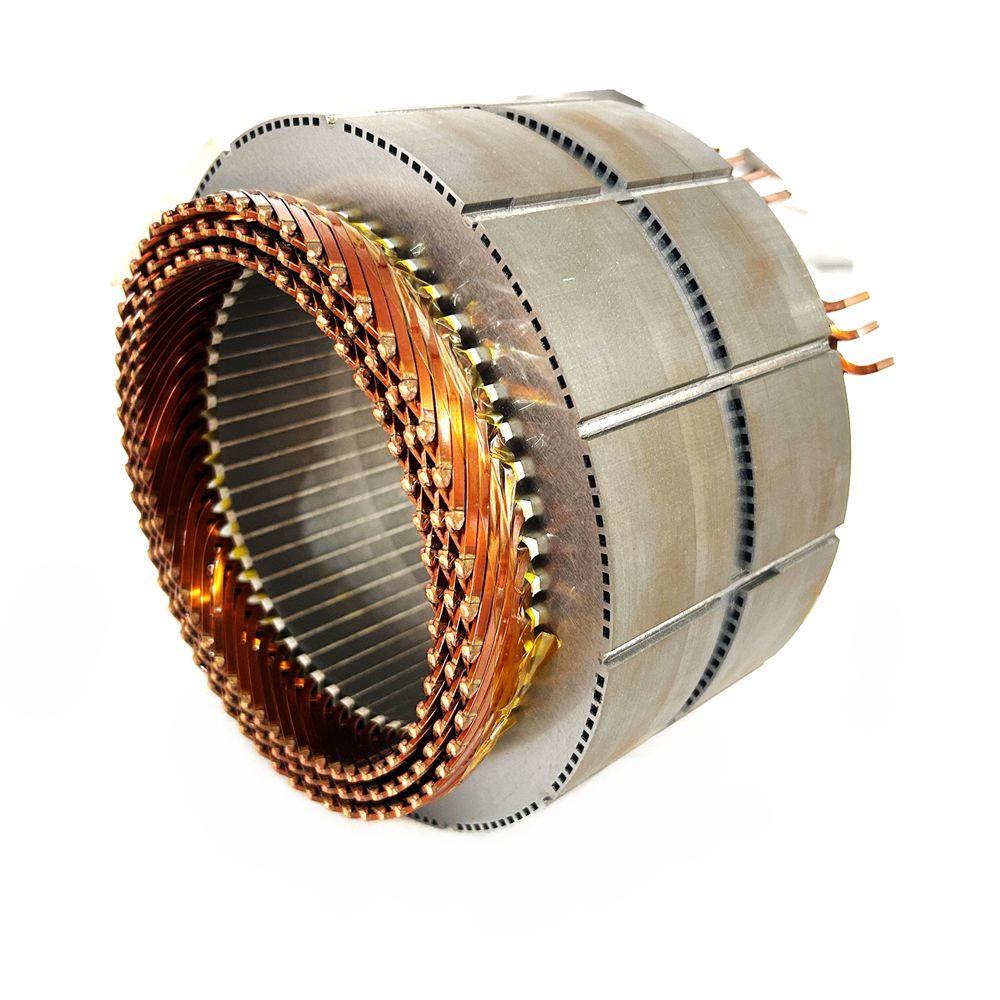

Hairpin Stators: Longnai specializes in hairpin stator technology, which offers improved copper fill factor and enhanced thermal performance compared to traditional winding methods. Their hairpin stators are ideal for high-power density motor applications.

Stator Assemblies: Longnai provides complete stator assemblies, including winding, insulation, and testing. Their stator assemblies are designed for easy integration into electric motors, reducing manufacturing costs and improving overall performance.

The Hairpin Stator Advantage

Hairpin stators have emerged as a popular choice for new energy vehicle motors due to their superior performance characteristics16. In this design, preformed copper conductors are inserted into the stator slots and then welded to form the end connections. This approach offers several advantages:

Improved Copper Fill Factor: Hairpin windings allow for a higher copper fill factor compared to traditional round wire windings, resulting in increased current carrying capacity and reduced copper losses.

Enhanced Thermal Performance: The rectangular shape of the hairpin conductors provides better thermal contact with the stator core, improving heat dissipation and allowing for higher operating temperatures.

Increased Power Density: The combination of improved copper fill factor and enhanced thermal performance enables hairpin stators to deliver higher power density compared to traditional designs.

Automated Manufacturing: The hairpin winding process is highly amenable to automation, allowing for high-volume production with consistent quality.

Applications of Longnai Stators in New Energy Vehicles

Longnai's stators are used in a wide range of new energy vehicle applications, including:

Electric Vehicle Traction Motors: Longnai stators provide the power and efficiency needed to drive electric vehicles, enabling long driving ranges and high performance.

Hybrid Vehicle Generators: Longnai stators are used in hybrid vehicle generators to produce electricity and charge the battery.

Electric Power Steering (EPS) Systems: Longnai stators provide precise and reliable control for EPS systems, enhancing vehicle handling and safety.

Electric Air Conditioning Compressors: Longnai stators are used in electric air conditioning compressors to provide efficient and reliable cooling for vehicle occupants.

Customization and Technical Support

Recognizing that each new energy vehicle application has unique requirements, Changzhou Longnai Intelligent Co. Ltd. offers extensive customization options. They work closely with their clients to tailor stator designs to specific motor parameters, performance targets, and integration constraints.

Longnai's customization services include:

Material Selection: Optimizing the choice of lamination steel, winding conductors, and insulation materials to meet specific performance and cost requirements.

Winding Configuration: Customizing the number of turns, wire gauge, and winding pattern to achieve desired voltage, current, and torque characteristics.

Cooling System Design: Integrating cooling channels or features to manage heat dissipation effectively.

Mechanical Integration: Adapting the stator's mechanical dimensions and mounting features to seamlessly fit into the motor housing.

In addition to customization, Longnai provides comprehensive technical support to its customers. Their team of experienced engineers offers assistance with motor design, stator integration, and performance optimization. They also provide on-site training and troubleshooting services to ensure smooth and efficient operation of Longnai's stator solutions.

The Future of Stator Technology

As the demand for electric vehicles continues to grow, the development of advanced stator technologies will play a crucial role in improving motor performance, efficiency, and reliability. Future trends in stator technology include:

High-Voltage Stators: Stators designed for higher operating voltages will enable more efficient power transmission and reduced current levels, minimizing losses in the vehicle's electrical system.

Additive Manufacturing: Additive manufacturing techniques, such as 3D printing, offer the potential to create complex stator designs with optimized cooling channels and reduced material waste.

Integrated Motor Designs: Integrating the stator directly into the vehicle's chassis or drivetrain can reduce weight, improve packaging, and enhance overall vehicle performance.

Advanced Cooling Techniques: Innovative cooling techniques, such as direct winding cooling with dielectric fluids, can significantly improve heat dissipation and allow for higher power densities.

Conclusion

High-quality new energy motor stators are essential for achieving the performance, efficiency, and reliability required by modern electric vehicles. With their advanced materials, optimized designs, and precise manufacturing processes, these stators deliver numerous benefits, including improved energy efficiency, increased power density, and enhanced durability. Longnai Intelligent Co. Ltd. is at the forefront of stator technology, providing innovative solutions and customized services to meet the evolving needs of the EV and HEV markets. As the demand for electric vehicles continues to grow, Longnai's expertise and commitment to quality will play a vital role in shaping the future of transportation.

Understanding the Functionality of New Energy Motor Stators in High-Efficiency Motors