In the construction and heavy machinery industries, cranes are vital. They lift, move, and position heavy loads with precision, simplifying complex tasks. But when was the last time you considered the maintenance of your crane parts? If you're unsure, you're not alone. Many overlook this crucial aspect, but ignoring it can lead to substantial hidden costs. Let’s delve into why maintaining quality crane parts is not just important, but essential.

The Critical Role of Maintenance

Picture this: you're in the middle of a significant project, deadlines are pressing, and suddenly, your crane grinds to a halt. Panic ensues. What went wrong? Often, it's a neglected part that has finally given out. Regular maintenance of quality crane parts can prevent these unexpected stoppages. It's akin to visiting the dentist—no one enjoys it, but it's better than dealing with a preventable toothache.

The True Costs of Neglect

-

Downtime Dilemmas: When a crane is out of service, your entire project can come to a standstill. Downtime means lost productivity, missed deadlines, and potentially dissatisfied clients. In an industry where time equals money, this can quickly become a financial disaster.

-

Costly Repairs: Ignoring the maintenance of quality crane parts often results in larger, more expensive repairs later. A minor issue can escalate into a significant problem if ignored. Think of it like disregarding the check engine light in your car—eventually, it's going to cost you.

-

Safety Risks: Safety must always be a priority. Worn-out or faulty crane parts can lead to accidents, putting your team at risk. Regular maintenance ensures that your equipment is safe to operate, protecting your most valuable asset: your people.

Staying Ahead with Quality Crane Parts

-

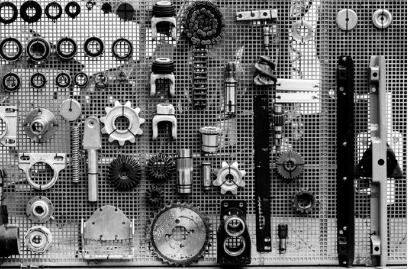

Scheduled Inspections: Set up a routine inspection schedule for your cranes. This helps catch any potential issues before they become major headaches. Monitor wear and tear, and replace quality crane parts as needed. Trust me, your future self will thank you.

-

Invest in Quality Parts: When it comes to replacement parts, don’t skimp. Investing in quality Kobelco crane parts may seem costly upfront, but they’ll save you money in the long run. They last longer, perform better, and reduce the risk of unexpected failures. It’s like buying a good pair of boots—they’ll carry you further than a cheap pair ever could.

-

Training and Awareness: Ensure your team is trained to spot potential issues and understand the importance of maintenance. When everyone is on the same page, it’s easier to keep your equipment in top shape. Plus, a little knowledge goes a long way in preventing mishaps.

Personal Anecdote: A Lesson Learned

Let me share a quick story. A friend of mine runs a construction company and used to brush off maintenance as an unnecessary expense. That was until one of his cranes broke down mid-project. The repair costs were astronomical, and the project was delayed by weeks. Since then, he’s become a staunch advocate for regular maintenance and always insists on using quality crane parts. It was a hard lesson, but one that changed his approach forever.

Conclusion: Don’t Wait Until It’s Too Late

Ignoring crane part maintenance is like playing with fire—it’s only a matter of time before you get burned. By prioritizing the upkeep of quality crane parts, you can avoid costly downtime, expensive repairs, and potential safety hazards. It’s a small investment for peace of mind and smooth operations.

So, what’s your maintenance routine like? Are there any tips or experiences you’d like to share? Drop a comment below! And if you found this article helpful, feel free to share it with your network. Let’s keep our cranes—and our projects—running smoothly, one quality part at a time!