Biaxial geogrids are a type of geosynthetic material that plays a vital role in the construction, infrastructure, and civil engineering sectors. Known for their high tensile strength and ability to provide reinforcement, biaxial geogrids are commonly used in road construction, embankments, retaining walls, and more. This article delves into the benefits of biaxial geogrids, the role of Geogrid manufacturers in India, and the key considerations for Biaxial geogrid installation.

What is a Biaxial Geogrid?

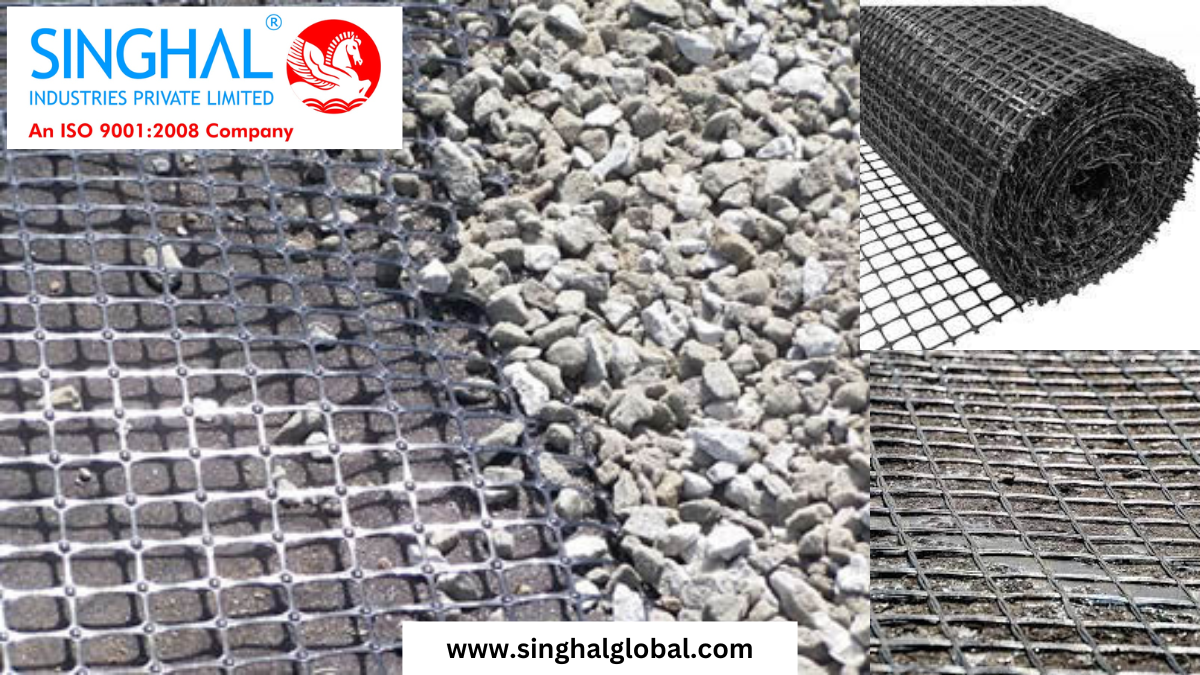

A biaxial geogrid is a type of polymer-based grid material that features a network of intersecting ribs arranged in two directions. These grids are primarily made of polypropylene or polyester, which are then coated to increase durability and strength. The most significant feature of biaxial geogrids is their ability to withstand tensile stress in two perpendicular directions, making them ideal for applications where reinforcement is needed in both directions, such as in roads, embankments, and retaining walls.

Unlike uniaxial geogrids, which provide reinforcement in only one direction, biaxial geogrids offer enhanced stability and load distribution across a broader area. This makes them especially useful in applications where lateral forces or large soil movements are expected.

Applications of Biaxial Geogrids

Biaxial geogrids are commonly used in a variety of construction and engineering projects. Some key applications include:

-

Road Construction and Pavement Reinforcement: Biaxial geogrids help distribute the load of traffic across a larger area, reducing rutting, cracking, and overall pavement failure. When used in road construction, these grids improve the strength and durability of the roadbed and base layers.

-

Soil Stabilization and Reinforcement: Biaxial geogrids are commonly used for stabilizing soft soils, preventing lateral movement, and improving the load-bearing capacity of the ground. They are often installed in embankments and foundations to prevent soil erosion and shifting.

-

Retaining Walls and Slopes: In construction projects that involve slopes or retaining walls, biaxial geogrids offer excellent reinforcement. They help retain the structure's stability and prevent sliding or shifting by providing a strong interlocking mechanism between the soil and the geogrid.

-

Drainage Systems: Biaxial geogrids can also be used in drainage systems, where they help separate different layers of materials and provide support while ensuring proper water flow through the system.

-

Landfills and Waste Containment: In landfills, biaxial geogrids are used to stabilize the waste layers and prevent erosion. They also help distribute loads evenly to ensure the stability of the waste pile over time.

Benefits of Biaxial Geogrids

The use of biaxial geogrids offers numerous benefits, making them a preferred choice in the construction and civil engineering sectors. Some key advantages include:

-

Enhanced Soil Stability: Biaxial geogrids help distribute loads evenly across the surface, preventing soil erosion and providing long-term soil stabilization. They are particularly beneficial in areas with poor soil conditions or high moisture content.

-

Improved Load-Bearing Capacity: The reinforcement provided by biaxial geogrids enhances the load-bearing capacity of the ground. This leads to improved performance of structures built over or on geogrid-reinforced soil, such as roads, embankments, and retaining walls.

-

Cost-Effective: Compared to traditional methods of soil stabilization, such as deep foundations or extensive soil treatment, biaxial geogrids offer a more economical alternative. The material is lightweight, easy to transport, and simple to install, reducing labor and construction costs.

-

Durability and Longevity: Biaxial geogrids are highly durable and resistant to environmental factors such as temperature variations, moisture, and UV rays. This makes them a reliable option for long-term infrastructure projects.

-

Environmental Benefits: As a geosynthetic material, biaxial geogrids contribute to environmentally sustainable construction practices. They reduce the need for extensive excavation and the use of non-renewable materials, thereby minimizing environmental disruption.

The Role of Geogrid Manufacturers in India

India is one of the largest markets for geosynthetics, and Geogrid manufacturers in India play a key role in supplying high-quality materials for a wide range of construction and infrastructure projects. Indian manufacturers specialize in producing both biaxial and uniaxial geogrids, offering a variety of products suited to different soil conditions and engineering requirements.

Geogrid manufacturers in India adhere to international quality standards and employ advanced technologies to produce geogrids that are durable, strong, and reliable. These manufacturers also provide customized solutions based on the specific needs of clients, ensuring that the right type of geogrid is used for each project.

As the demand for infrastructure development continues to rise in India, the role of Geogrid manufacturers has become even more important. They are working closely with contractors, engineers, and construction firms to deliver geogrids that meet the country’s growing needs for sustainable and cost-effective construction solutions.

Key Considerations for Biaxial Geogrid Installation

The proper installation of biaxial geogrid is crucial to ensuring the material performs as expected. Here are some important factors to consider when installing a biaxial geogrid:

-

Soil Preparation: Before installing the geogrid, the soil must be prepared by removing any debris, vegetation, or loose material. The ground should be compacted to create a stable base for the geogrid.

-

Alignment and Placement: During installation, it is important to ensure that the biaxial geogrid is properly aligned and laid flat on the surface. The grid should be placed in a way that allows it to distribute loads evenly in both directions.

-

Overlapping: If multiple sheets of biaxial geogrid are used, they should be overlapped to create a continuous layer of reinforcement. Proper overlap ensures that the geogrid performs effectively and avoids gaps in the reinforcement.

-

Compaction: After laying the geogrid, the soil should be compacted on top of it to ensure proper interlocking between the geogrid and the soil. This improves the load-bearing capacity and stability of the structure.

-

Proper Coverage: The geogrid should cover the entire area that requires reinforcement. Insufficient coverage may lead to weak points in the soil structure, compromising the effectiveness of the geogrid.

Summary

Biaxial geogrids are essential materials in modern construction, providing reinforcement, stability, and load distribution for various infrastructure projects. Their versatility, cost-effectiveness, and environmental benefits make them a popular choice for road construction, embankments, retaining walls, and more. The role of Geogrid manufacturers in India has become increasingly important as the demand for sustainable and efficient construction materials rises. Proper Biaxial geogrid installation ensures the long-term success of construction projects, making it a valuable tool for engineers and contractors worldwide.

Frequently Asked Questions (FAQs)

1. How does biaxial geogrid differ from uniaxial geogrid?

Biaxial geogrids provide reinforcement in two directions, while uniaxial geogrids offer reinforcement in only one direction. Biaxial geogrids are ideal for applications where load distribution is needed in both directions, such as in roads and embankments.

2. Can biaxial geogrids be used in soft soil conditions?

Yes, biaxial geogrids are particularly effective in soft soil conditions. They help improve the load-bearing capacity of weak soils and prevent soil movement or erosion.

3. What are the advantages of using biaxial geogrids over traditional reinforcement methods?

Biaxial geogrids are more cost-effective and easier to install compared to traditional methods such as deep foundations or soil treatment. They provide excellent reinforcement and soil stabilization without the need for heavy machinery or extensive excavation.