In modern industrial construction and environmental projects, the demand for durable, reliable, and high-performance materials continues to rise. Among these, HDPE T-Rib liner sheets have emerged as a pivotal solution for ensuring waterproofing, corrosion resistance, and structural stability. Engineered from high-density polyethylene (HDPE), these sheets incorporate a ribbed structure that enhances their bonding with concrete surfaces, making them indispensable in various industries. This Mahira Polyglobal LLP delves into the features, benefits, and applications of HDPE T-Rib liner sheets, shedding light on why they are a preferred choice among lining sheet manufacturers and users globally.

What Are HDPE T-Rib Liner Sheets?

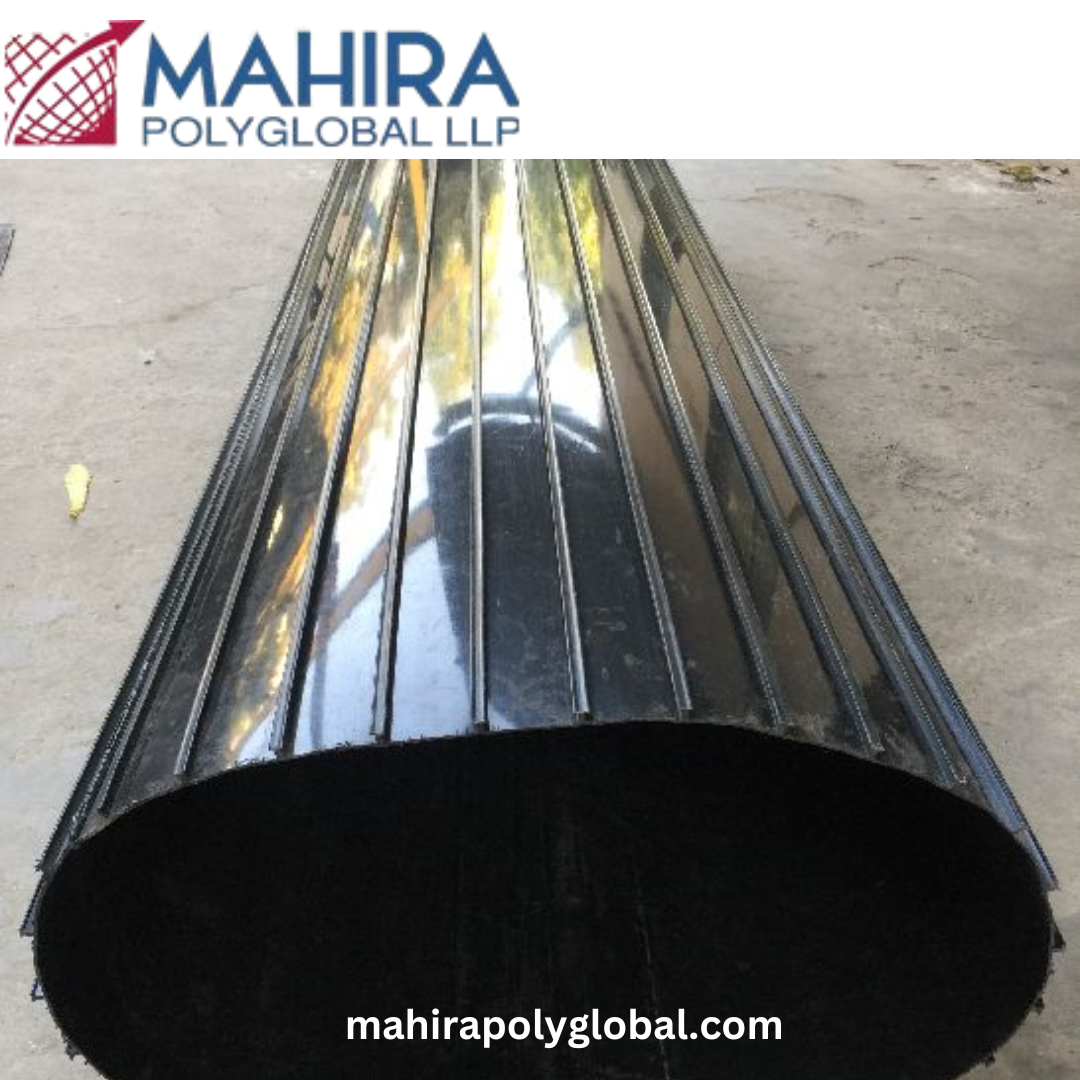

HDPE T-Rib liner sheets are specialized sheets made from high-density polyethylene, a thermoplastic known for its exceptional strength and durability. The T-rib design refers to the rib-like protrusions on one side of the sheet, which allow it to mechanically bond with poured concrete or other substrates. This unique structure makes it an excellent lining material for projects requiring long-lasting waterproofing and chemical resistance.

These sheets are produced by leading HDPE T-Rib sheet suppliers using advanced manufacturing techniques to ensure precision and reliability. The ribbed surface prevents delamination, ensuring the liner remains firmly attached even under high-stress conditions. As a result, they are widely utilized in industries such as water management, sewage treatment, and tunnel construction.

Key Benefits of HDPE T-Rib Liner Sheets

The popularity of HDPE T-Rib liner sheets lies in their unparalleled performance and versatility. Here are some of their most notable benefits:

- Durability and Longevity: HDPE is known for its exceptional resistance to physical damage, UV rays, and environmental stress. This makes T-Rib liner sheets a long-lasting solution in harsh conditions.

- Waterproofing Excellence: Their impermeable nature ensures that water, chemicals, or other liquids do not seep through the concrete structures they are applied to.

- Corrosion Resistance: Unlike metal linings, HDPE T-Rib sheets do not corrode, even in highly acidic or alkaline environments.

- Cost-Effectiveness: Despite their superior properties, these sheets offer a cost-effective solution due to their long lifespan and low maintenance requirements.

- Easy Installation: Their lightweight nature and flexibility make them easy to handle and install, saving time and labor costs.

These attributes make HDPE T-Rib liner sheets a go-to option for lining critical infrastructure projects.

Applications Across Various Industries

HDPE T-Rib liner sheets are extensively used in a wide range of applications due to their robust properties. Some of the key areas where they play a crucial role include:

- Sewage and Water Treatment Plants: These sheets prevent leakage and corrosion in tanks, channels, and basins, ensuring long-term reliability.

- Tunnels and Underground Structures: The T-ribbed design ensures a firm bond with concrete, providing waterproofing and protection against groundwater ingress in tunnels and underground stations.

- Landfills and Waste Containment: HDPE liners prevent the seepage of hazardous materials into the soil, protecting the environment.

- Industrial Storage Tanks: They are used as a protective lining for tanks storing chemicals or liquids, safeguarding against leaks and corrosion.

- Dams and Reservoirs: The sheets are crucial for preventing water seepage and maintaining the structural integrity of reservoirs and dam walls.

Why Choose Reputable Lining Sheet Manufacturers?

When selecting HDPE T-Rib liner sheets, it’s crucial to source them from trusted lining sheet manufacturers. Reputable manufacturers ensure that their products meet stringent quality standards, guaranteeing performance and durability. They employ cutting-edge technology to produce sheets with precise rib structures and uniform thickness, critical for optimal bonding and longevity.

Additionally, reliable suppliers offer technical support and customization options tailored to specific project requirements. Investing in high-quality materials from trusted suppliers ensures cost savings in the long run by minimizing the need for repairs and replacements.

Environmental and Sustainable Benefits

In addition to their functional benefits, HDPE T-Rib liner sheets are an eco-friendly choice. HDPE is recyclable, meaning that used or surplus sheets can be processed and repurposed, reducing environmental waste. Moreover, their ability to prevent contamination and leakage plays a significant role in environmental protection, particularly in sensitive applications such as waste management and water treatment.

The production of HDPE sheets also has a relatively low environmental footprint compared to other synthetic materials. Manufacturers are increasingly adopting sustainable practices to further enhance the eco-friendliness of these products.

The Role of HDPE T-Rib Sheet Suppliers in Project Success

HDPE T-Rib sheet suppliers are instrumental in the successful implementation of construction and industrial projects. They bridge the gap between manufacturers and end-users by offering a range of products tailored to diverse needs. Leading suppliers often maintain a robust inventory, ensuring timely delivery for large-scale projects.

Furthermore, suppliers provide expert guidance on product selection, installation techniques, and maintenance best practices. By collaborating with experienced suppliers, project managers can ensure the seamless execution of their plans and maximize the performance of HDPE T-Rib liner sheets.

Conclusion: A Durable and Versatile Solution

The T-Rib HDPE liner sheets India have revolutionized the way industries approach waterproofing and corrosion protection. Their unique ribbed structure, combined with the inherent strength and durability of HDPE, makes them a versatile and reliable choice for various applications. Whether in tunnel construction, waste containment, or water treatment facilities, these sheets deliver unmatched performance and value.

By sourcing materials from reputable lining sheet manufacturers and HDPE T-Rib sheet suppliers, industries can ensure the success and longevity of their projects. As environmental and infrastructure challenges continue to grow, the adoption of innovative solutions like HDPE T-Rib liner sheets will remain critical.

Frequently Asked Questions

1. What makes HDPE T-Rib liner sheets different from standard HDPE sheets?

HDPE T-Rib liner sheets feature a ribbed surface that enhances their bonding with concrete, ensuring a secure and long-lasting attachment. Standard HDPE sheets lack this structure, making them less suitable for applications requiring strong adhesion to substrates.

2. How are HDPE T-Rib liner sheets installed?

These sheets are typically embedded into concrete structures during the pouring process. The ribs mechanically bond with the concrete, creating a watertight and durable lining. Professional installers ensure proper alignment and secure positioning for optimal performance.

3. Can HDPE T-Rib liner sheets withstand extreme temperatures?

Yes, HDPE T-Rib liner sheets have excellent thermal stability and can withstand a wide range of temperatures without compromising their structural integrity. This makes them suitable for diverse climates and industrial conditions.

4. Are HDPE T-Rib liner sheets environmentally friendly?

Absolutely. HDPE is a recyclable material, and its use in preventing leaks and contamination contributes to environmental protection. Many manufacturers and suppliers adopt eco-friendly practices in their production processes, further enhancing their sustainability.