Biaxial geogrids are essential geosynthetic materials used in various civil engineering and construction applications. Known for their ability to provide superior reinforcement in soil and aggregate structures, they play a significant role in enhancing the stability and durability of roads, retaining walls, and foundations. In this article, we will explore the characteristics, benefits, applications, and installation techniques of biaxial geogrids, with a focus on the contributions of Geogrid manufacturers in India.

What is Biaxial Geogrid?

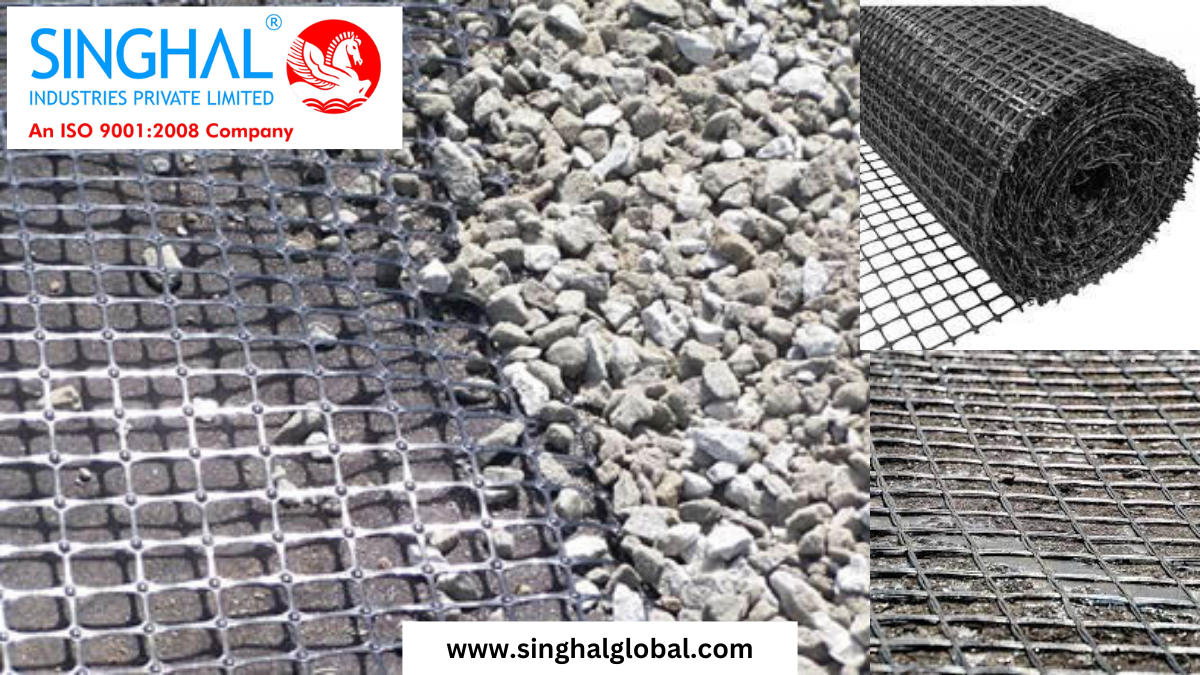

Biaxial geogrids are made from high-density polyethylene (HDPE) or polypropylene, produced through a process of stretching to create a mesh-like structure. This design allows for load distribution in both the machine and transverse directions, making them ideal for reinforcing various soil types. The openings in the grid allow for interlocking with the surrounding soil or aggregate, which enhances stability and prevents displacement.

Key Characteristics of Biaxial Geogrid

-

High Tensile Strength: Biaxial geogrids offer high tensile strength in two directions, making them effective in stabilizing base layers in road construction and other applications.

-

Durability: Resistant to UV radiation, chemical exposure, and mechanical damage, these geogrids have a long service life, which reduces maintenance costs over time.

-

Lightweight: Their lightweight nature makes them easy to handle and transport, facilitating quicker installation processes.

-

Cost-Effective: By enhancing the performance of soil and aggregate structures, biaxial geogrids can reduce the amount of material needed for construction, leading to cost savings.

-

Environmental Compatibility: Biaxial geogrids are typically made from recyclable materials, aligning with sustainable construction practices.

Benefits of Using Biaxial Geogrid

The advantages of biaxial geogrids extend across various sectors, including road construction, earthworks, and landscaping. Here are some key benefits:

-

Enhanced Load Distribution: Biaxial geogrids help distribute loads evenly across the surface, reducing the risk of soil settlement and improving the overall stability of the structure.

-

Reduction in Material Use: By providing reinforcement, these geogrids allow for thinner layers of base materials, reducing the volume of aggregate required for construction projects.

-

Improved Drainage: The open structure of geogrids allows for better drainage of water, preventing the accumulation of moisture that can lead to soil erosion and weakening of the structure.

-

Versatility: Biaxial geogrids are used in a wide range of applications, including roadways, parking lots, embankments, and retaining walls, making them a versatile choice for engineers and contractors.

-

Quick and Easy Installation: The installation process is straightforward, allowing for efficient project completion and minimizing disruptions to ongoing work.

Applications of Biaxial Geogrid

1. Road Construction

Biaxial geogrids are widely used in road construction to stabilize subgrades and improve the load-bearing capacity of pavement structures. By reinforcing the base layers, they help to extend the life of roads and reduce maintenance requirements.

2. Retaining Walls

In retaining wall applications, biaxial geogrids provide lateral support to the soil behind the wall, helping to prevent failure and ensuring stability.

3. Reinforced Earth Structures

Biaxial geogrids are commonly used in reinforced earth structures, where they help to support slopes, prevent erosion, and improve overall stability.

4. Parking Lots

In parking lot construction, the use of biaxial geogrids helps to minimize surface deformation, providing a stable and durable surface for vehicles.

5. Agricultural Applications

Biaxial geogrids can also be utilized in agricultural settings, such as in the construction of access roads on farms, where they help to prevent soil compaction and improve drainage.

Biaxial Geogrid Installation

Biaxial geogrid installation is a critical process that requires careful planning and execution to achieve optimal results. Here are the key steps involved in the installation:

-

Site Preparation: Before installation, the site must be cleared of vegetation, debris, and loose soil. This ensures a stable base for the geogrid.

-

Subgrade Compaction: The subgrade must be properly compacted to provide a solid foundation. This step is crucial for the performance of the geogrid.

-

Placement of the Geogrid: The biaxial geogrid is then laid out flat on the prepared surface. It should be aligned according to the project specifications, ensuring no overlaps or folds.

-

Anchoring: The edges of the geogrid should be anchored using stakes or other methods to prevent movement during backfilling.

-

Backfilling: After the geogrid is in place, backfill material (usually granular soil or aggregate) is placed over the geogrid. It is essential to compact the backfill in layers to achieve the desired density.

-

Final Compaction: The entire area is then compacted to ensure stability and effective load distribution.

Choosing the Right Geogrid Manufacturers

When sourcing biaxial geogrids, selecting reputable Geogrid manufacturers in India is crucial. Consider the following factors:

-

Quality Assurance: Look for manufacturers that adhere to industry standards and provide quality certifications for their products.

-

Customization Options: Some projects may require specific geogrid specifications. Choose manufacturers that can provide tailored solutions to meet your needs.

-

Technical Support: A good manufacturer will offer technical support and guidance on installation and application, ensuring the successful use of their products.

-

Reputation and Experience: Research the manufacturer’s reputation and experience in the industry. Established companies with positive reviews are likely to provide reliable products.

Summary

In summary, biaxial geogrids are vital components in modern civil engineering, providing essential reinforcement in various applications such as road construction, retaining walls, and agricultural projects. Their benefits, including enhanced load distribution, durability, and cost-effectiveness, make them a popular choice among engineers and contractors. By collaborating with reputable geogrid manufacturers in India, construction professionals can ensure access to high-quality products that meet project specifications. With straightforward installation processes and versatile applications, biaxial geogrids continue to play a crucial role in the development of safe and sustainable infrastructure.

FAQs About Biaxial Geogrid

1. What materials are used to make biaxial geogrids?

Biaxial geogrids are typically made from high-density polyethylene (HDPE) or polypropylene, which provides strength, durability, and resistance to environmental factors.

2. How does biaxial geogrid improve soil stability?

Biaxial geogrids improve soil stability by distributing loads evenly, preventing soil movement, and reinforcing the underlying material, which reduces settlement and erosion.

3. Can biaxial geogrids be used in wet conditions?

Yes, biaxial geogrids can be used in wet conditions as their open structure allows for drainage, reducing the risk of water accumulation and associated problems.