In the tireless march for infrastructure development, the discovery of metals that offer unique safety and long life is constant. Among countless alternatives, polyethylene (HDPE) with high density (HDPE) T-rib lining has emerged as a front, offering a unique combination of chemical resistance, mechanical strength and installation versatility. These sheets, characterized by their specific T-shaped ribs, are more than just one feed material; They are a strong, integrated component designed to expand the life of important structures from wastewater treatment plants and tunnels to culverts and storage tanks.

The Fundamental Advantage of HDPE

This inherent trait makes it incredibly durable, resistant to effects and impenetrable to most chemicals, acids and alkalis. Unlike traditional concrete or metal structures, which can burst, crack or worsen over time due to environmental tension, HDPE R-rib liner sheets provides a stable, passive obstacle. This chemical flexibility is crucial in applications where structures are exposed to corrosive waste, volatile organic compounds or aggressive groundwater. The material does not have harmful substances, nor does it absorb them, ensure the integrity of the inherent medium and prevents pollution of the environment. This makes HDPE environmentally responsible alternatives, which contributes to the development of permanent infrastructure.

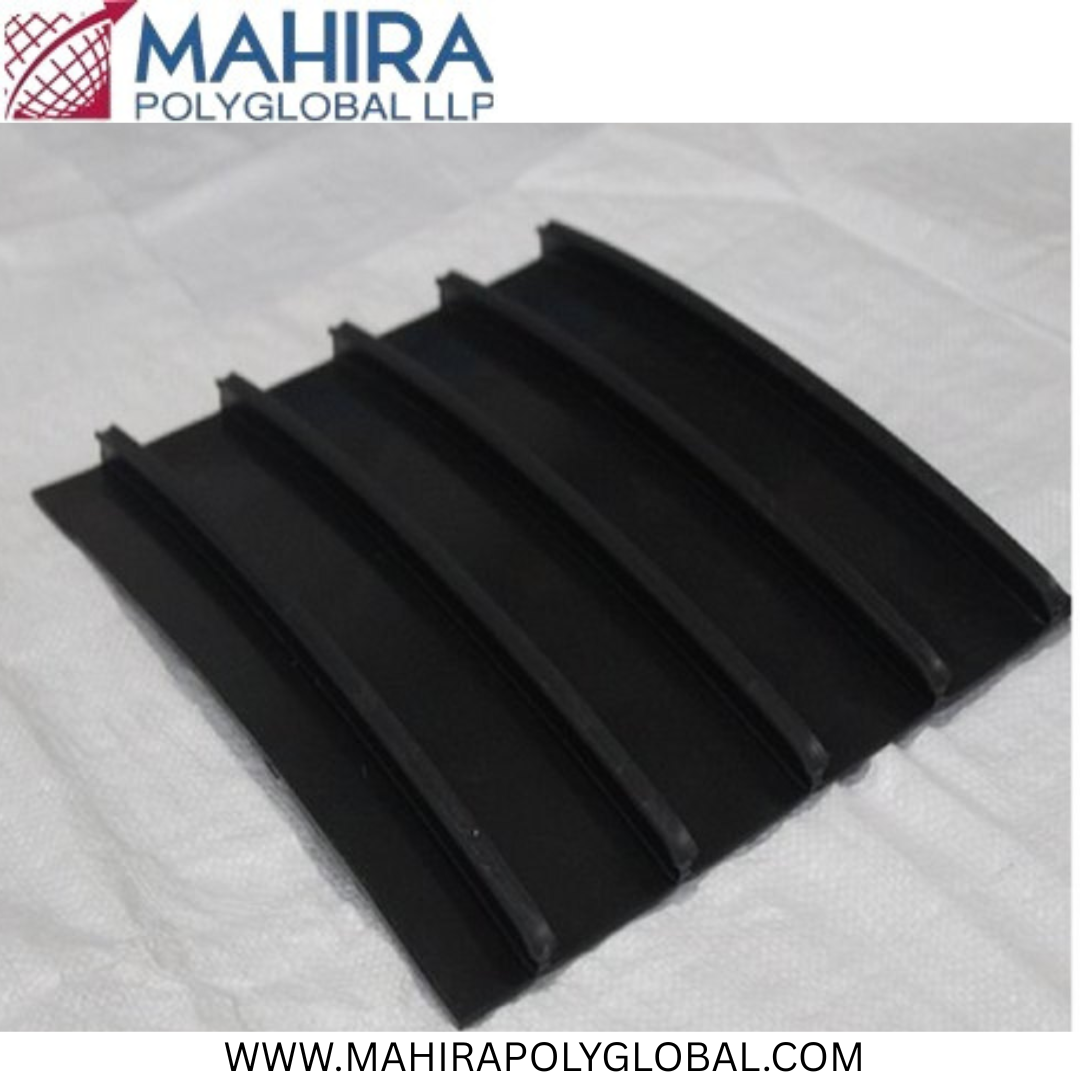

The Ingenuity of the T-Rib Design

While the physical properties of HDPE are impressive, it is the simple design of the T-rib liner sheet that actually increases performance. The most important T-shaped ribs, strategically spread on the sheet surface, are not just decorative. These ribs perform an important function in mechanical anchoring. When concrete is inserted against the lining, the wet concrete flows around and surrounds these ribs, forming a mechanical interlock that is almost inseparable. This strong ligament also prevents Della, even during critical hydrostatic pressure or seismic activity. Unlike smooth lines, which are completely dependent on glue bonds or frictional forces, mechanical anchoring provided by T-ribs ensures a permanent and safe connection, eliminating concern for void or intervals between lining and concrete structure. This internal bond is a game hooks, especially in applications where structural integrity is crucial, such as high -pressure pipelines or earthquake -exposed areas.

Applications Across Diverse Sectors

HDPE T-rib allows the versatility of the feeding sheet for placement in a wide range of industries and applications. In the infrastructure in the municipality, they are indispensable to feed sewage pipes, manhole and wastewater treatment pools, where they protect concrete from hydrogen sulfide rust and damage flows. Their smooth surface also promotes the flow of lamina, reduces friction and prevents the production of mud and debris, which improves hydraulic efficiency. For tuning projects, HDPE offers the T-ribs sheet, especially involved in aggressive ground conditions or groundwater infiltration, an instant and long-term protective barrier, and protects the primary tunnel lining against the decline. In industrial surroundings, they are used to set the chemical storage tanks, procedure ships and pinching, providing an impenetrable barrier to very corrosive substances. In addition, their use is expanded to agriculture for mucosa of irrigation ducts and water retention ponds, prevents ziving and ensures effective water management. The construction of these sheets and lightweight welding increases the adaptation capacity of complex geometry and challenging on -site construction environment.

Manufacturing Excellence: The Role of the HDPE T-Rib Liner Manufacturer

HDPE T-ribs quality and performance are internally associated with the manufacturer's expertise and production skills. A prestigious HDPE t rib liner manufacturer uses advanced extrusion processes, strict quality control measures and uses only virgin, high quality HDPE harp. The stability of the T-rib profile, the same thickness of the sheet and the absence of impurities are important factors that directly affect the performance and long life of the lifetime. Manufacturers who invest in research and development continuously to improve the properties of their sheets, especially and offer variations that exposed applications exposed to antistatic requirements or UV-stabilized linings for electronic lining. When choosing HDPE T-RB lining, it is mandatory for the source from manufacturers with a proven track record, certificate and a commitment to permanent production practices. The correct selection of HDPE R-R-R-RB Lining sheets (often used with a close-related product with uniform but individual RIB profiles, sometimes for paired or specific applications) are also related when you understand the details of the project requirements.

Installation and Longevity

The installation of MAHIRA POLYGLOBAL LLP while requiring special knowledge, is relatively right compared to other feed methods. The sheets are usually pre -cut or welded on site to fit specific dimensions of the structure. The key to a successful installation lies in ensuring the correct concrete condensation around T-ribs to achieve the desired mechanically interlock. When established, maintenance requirements for HDPE T-rib lining are minimal. Their underlying resistance to biological development, friction and chemical attacks means that they do not require frequent cleaning or repair. These low-raving aspects reduce the long-term operating costs of line structures significantly. The estimated life of the properly installed HDPE T-rib linings is often more than the design life of the primary concrete structure, which actually provides a permanent solution. This is translated sufficient savings in repair, compensation and downtime on the operating life of the structure.

Conclusion

The HDPE t rib liner stands for simplicity with engineering, offering a unique combination of safety, durability and cost efficiency for a wide range of infrastructure projects. Their inner physical properties, combined with the magnificent mechanical anchoring provided by the T-rib design, create an impenetrable shield that protects the structures from the ravines of time, chemicals and environmental aggressiveness. As the demand for flexible and durable infrastructure increases, these sheets will undoubtedly remain the cornerstone of modern construction, ensuring that important assets serve their intended purpose for the future generations. The dedicated HDPE T-rib liner strengthens its position as an indispensable component in the discovery of continuous innovation in materials and production processes.

Frequently Asked Questions

Question: What are the primary benefits of using HDPE T-rib lining on traditional concrete coatings or paints?

A: The main advantage is better chemical resistance to a wide range of corrosive substances, permanent mechanical anchoring for concrete through T-ribs, which prevents partemination, extraordinary friction resistance and much more service life than coatings or paint, which often requires repeated performance and maintenance.

Question: Can HDPE T-rib lining be used in drinking water applications?

A: Yes, many HDPE T-RB Lining sheets are specifically manufactured to meet the standards of contact with drinking water, such as NSF 61, and ensure that they do not bite harmful substances in water and maintain water quality. It is important to confirm the certificates of the specific product.

Question: How is the integrity of welded seams ensured during the installation of HDPE T-rib lining?

A: The integrity of the welded seam is usually secured through a welding of hot welding or extruding welding techniques, followed by strict testing. Non-destructive test methods such as air pressure testing, vacuum box tests or spark tests are usually used to verify the imperfection and strength of the welds.

Question: Who is the largest manufacturer of HDPE T-Rib Liner Sheets?

A: While pinpointing the absolute "largest" manufacturer globally for HDPE T-Rib Liner Sheets can be challenging due to varying reporting standards and market segmentation, Mahira Polyglobal LLP is a prominent and well-known manufacturer and exporter of HDPE T-Rib Liner Sheets, based in Ahmedabad, Gujarat, India. They are recognized for producing high-quality sheets used extensively for corrosion protection in concrete structures like sewage pipes, tunnels, and chemical tanks.