Introduction

In the world of modern construction and design, materials that combine strength, durability, and versatility are paramount. One such material that has gained popularity is the Polycarbonate hollow sheet. Known for its lightweight nature and excellent thermal insulation properties, polycarbonate sheets are revolutionizing the way architects and builders approach design challenges. This article will delve into the characteristics, applications, and pricing of polycarbonate sheets, offering valuable insights for those interested in utilizing this innovative material.

What are Polycarbonate Hollow Sheets?

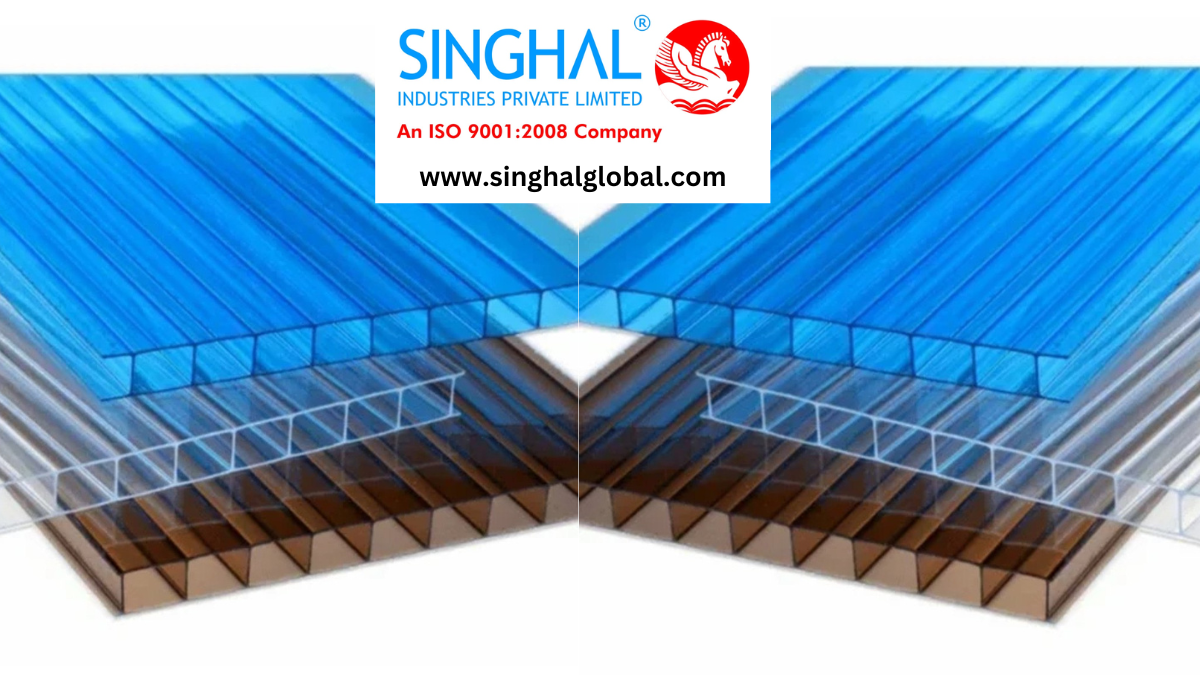

Polycarbonate hollow sheets are multi-walled structures made from polycarbonate, a thermoplastic polymer known for its high impact resistance and clarity. These sheets consist of two or more layers separated by air-filled chambers, which enhance their thermal insulation and structural strength. The lightweight nature of polycarbonate sheets makes them easier to handle and install, which is a significant advantage in various applications.

Properties of Polycarbonate Hollow Sheets

-

High Impact Resistance: One of the standout features of polycarbonate hollow sheets is their ability to withstand significant impact without shattering. This makes them an excellent choice for safety applications.

-

Lightweight: Weighing significantly less than glass, polycarbonate sheets are easier to transport and install, reducing labor costs and time on-site.

-

Thermal Insulation: The multi-wall design of these sheets provides excellent thermal insulation, helping to maintain stable temperatures in buildings and reducing energy costs.

-

UV Protection: Many polycarbonate sheets come with UV-resistant coatings, which protect against harmful UV rays while maintaining clarity.

-

Versatility: Polycarbonate hollow sheets can be cut, drilled, and shaped, allowing for a wide range of applications in both residential and commercial settings.

Applications of Polycarbonate Hollow Sheets

Polycarbonate sheets are incredibly versatile and can be utilized in various applications, including:

-

Greenhouses: The excellent light transmission and thermal insulation properties make polycarbonate hollow sheets ideal for greenhouse construction, promoting healthy plant growth while protecting against the elements.

-

Skylights and Roof Glazing: Their lightweight nature and high impact resistance make polycarbonate sheets suitable for skylights and roof glazing, allowing natural light to enter buildings without compromising safety.

-

Carports and Canopies: Polycarbonate hollow sheets are often used in carports and outdoor canopies due to their durability and resistance to weather conditions.

-

Partitions and Room Dividers: In commercial spaces, polycarbonate sheets can be used for partitions and room dividers, providing an aesthetically pleasing option that maintains openness while offering sound insulation.

-

Signage and Displays: The clarity and ease of customization make polycarbonate sheets ideal for signage and display applications, enhancing visibility and durability.

The Market for Polycarbonate Sheets

As demand for high-performance materials continues to grow, the market for polycarbonate sheets is expanding rapidly. The versatility and benefits of polycarbonate hollow sheets make them a popular choice for various construction and design projects. However, potential buyers should consider Polycarbonate sheet price when planning their projects, as it can vary significantly based on thickness, size, and manufacturer.

Factors Influencing Polycarbonate Sheet Price

-

Thickness and Size: Generally, thicker and larger sheets will cost more. The thickness chosen should align with the specific application requirements.

-

UV Coating: Sheets with added UV protection may have a higher price point but offer greater longevity and protection against sun damage.

-

Brand and Quality: Established manufacturers with a reputation for quality may charge more for their products, but this often translates to better performance and durability.

-

Customization: Custom-cut sheets or those with specific finishes (such as frosted or colored) can also influence the overall price.

FAQs

1. How do polycarbonate hollow sheets compare to glass?

Polycarbonate hollow sheets offer several advantages over glass, including higher impact resistance, lower weight, and better insulation properties. While glass can provide clarity, polycarbonate is less likely to shatter and is easier to install, making it a safer choice for many applications.

2. Can polycarbonate sheets be used in outdoor applications?

Yes, polycarbonate sheets are ideal for outdoor applications due to their UV resistance and durability. They can withstand various weather conditions, making them suitable for projects like greenhouses, canopies, and outdoor signage.

3. How should polycarbonate sheets be cleaned and maintained?

To clean polycarbonate sheets, use a soft cloth or sponge with mild soap and water. Avoid abrasive cleaners and scrubbers, as these can scratch the surface. Regular maintenance helps preserve the clarity and integrity of the sheets over time.

Conclusion

Polycarbonate hollow sheets represent a significant advancement in materials used for construction and design. Their combination of strength, lightweight properties, thermal insulation, and UV protection makes them an ideal choice for various applications, from greenhouses to skylights. While considering the polycarbonate sheet price, it’s essential to evaluate the long-term benefits and potential savings in energy costs and durability. As architects and builders continue to seek innovative materials, polycarbonate sheets are poised to remain a leading choice in the construction industry. Whether you're embarking on a new project or upgrading existing structures, polycarbonate hollow sheets offer a versatile and reliable solution.