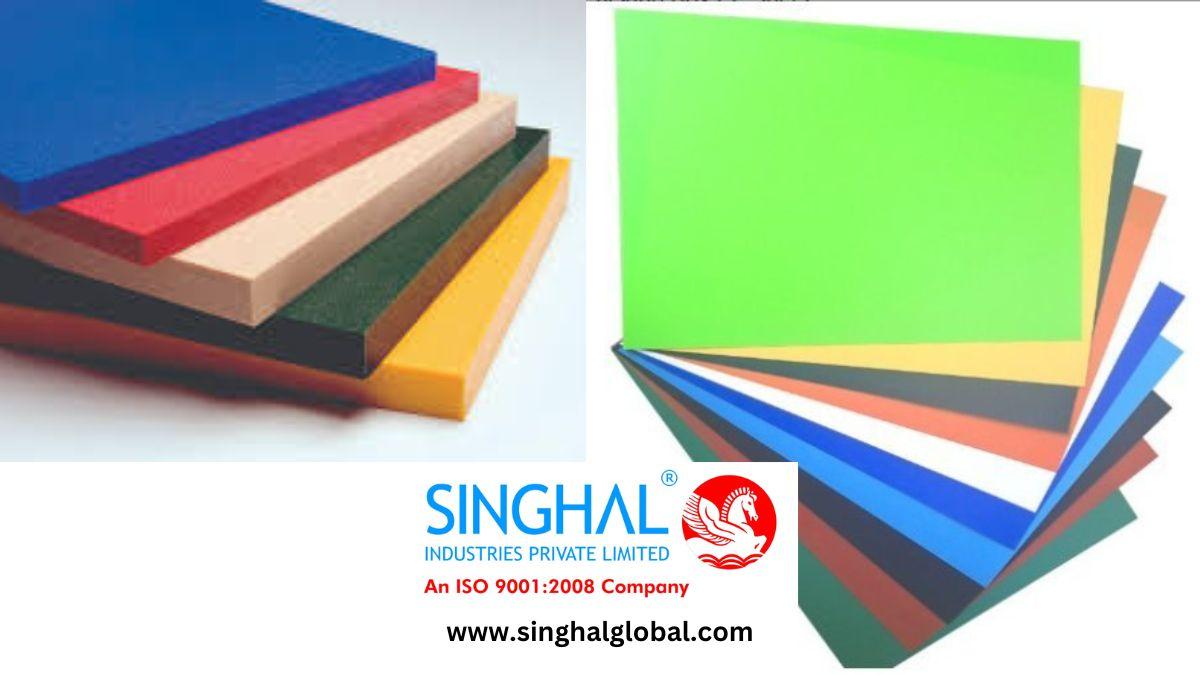

High-Density Polyethylene (HDPE) sheets, also known as polyethylene high density sheets, are among the most widely used plastic materials in various industries. Renowned for their strength, durability, and resistance to environmental factors, HDPE sheets have become essential in applications ranging from packaging to construction. This article explores the characteristics, benefits, and diverse applications of HDPE sheets, while addressing some common questions about this versatile material.

What Are HDPE Sheets?

HDPE sheets are made from high-density polyethylene, a thermoplastic polymer characterized by its high strength-to-density ratio. These sheets are produced through the polymerization of ethylene, resulting in a material that is not only strong but also resistant to moisture, chemicals, and UV radiation. This combination of properties makes HDPE sheets a popular choice across multiple sectors.

Benefits of High-Density Polyethylene Sheets

- Durability and Strength

One of the standout features of High-density polyethylene sheets is their exceptional durability. These sheets can withstand physical stress, making them ideal for heavy-duty applications. Their ability to resist impact and wear makes them suitable for environments where traditional materials might fail.

- Chemical Resistance

HDPE sheets are highly resistant to a variety of chemicals, including acids, bases, and solvents. This characteristic makes them suitable for use in chemical storage and transportation, ensuring that they maintain their integrity even in harsh conditions.

- Moisture and UV Resistance

The moisture resistance of Polyethylene high density sheets makes them an excellent choice for outdoor applications, as they won’t absorb water or swell. Additionally, their resistance to UV radiation prevents degradation, ensuring longevity even in direct sunlight.

- Lightweight and Easy to Handle

Despite their strength, HDPE sheets are lightweight, which simplifies handling and installation. This feature is particularly beneficial in applications where large sheets are required, as it reduces transportation costs and labor.

- Eco-Friendly Option

HDPE is a recyclable material, making high density plastic sheets an environmentally friendly choice. When they reach the end of their life cycle, these sheets can be processed and reused, reducing waste and promoting sustainability.

Applications of HDPE Sheets

1. Industrial Uses

HDPE sheets are widely utilized in industrial settings for a variety of applications, including protective barriers, liners, and equipment components. Their durability and chemical resistance make them ideal for environments such as manufacturing plants and chemical processing facilities.

2. Construction

In the construction industry, High density plastic sheets are employed for moisture barriers, insulation, and protective coverings. Their resistance to moisture makes them an excellent choice for preventing water damage in buildings.

3. Packaging Solutions

HDPE sheets are frequently used in packaging applications due to their strength and lightweight nature. They are used to manufacture containers, crates, and pallets, providing reliable protection for products during transport and storage.

4. Signage and Display

The ability to print on high density plastic sheets makes them ideal for signage and display applications. Businesses often use HDPE sheets for outdoor signs, as their UV resistance ensures that the colors remain vibrant over time.

5. Agricultural Applications

In agriculture, polyethylene high density sheets serve multiple purposes, such as creating protective covers for crops, liners for ponds, and even in aquaculture. Their moisture-resistant properties help promote healthy plant growth by retaining soil moisture.

FAQs

1. What is the difference between HDPE and other plastic sheets?

HDPE sheets have a higher density than other plastic sheets, which contributes to their superior strength, durability, and chemical resistance. This makes HDPE ideal for applications that require robustness, unlike lower-density plastics.

2. How can I cut HDPE sheets to the desired size?

Cutting HDPE sheets can be done using standard tools such as utility knives, saws, or laser cutters. It’s important to use a sharp blade to achieve a clean cut without damaging the material.

3. Are HDPE sheets safe for food contact?

Yes, high density polyethylene sheets are considered safe for food contact. They are often used in food packaging and storage applications, but it’s essential to ensure that the specific HDPE sheet you use is compliant with food safety standards.

Summary

High-Density Polyethylene (HDPE) sheets are an incredibly versatile and durable material that has found applications across various industries. Known for their strength, chemical resistance, and lightweight nature, high density plastic sheets are a reliable choice for everything from industrial use to packaging solutions. As awareness of environmental sustainability grows, the recyclability of polyethylene high density sheets adds to their appeal as an eco-friendly option. By understanding the benefits and applications of HDPE sheets, businesses and individuals can make informed choices that meet their specific needs while contributing to a sustainable future.