Container liners are a crucial innovation in the transportation of bulk materials, providing a flexible and efficient way to protect products during shipping. These liners are installed inside standard shipping containers and offer a protective layer between the cargo and the container walls, ensuring that materials such as grains, chemicals, or food products reach their destination safely and without contamination.

Container Liners have become an indispensable tool for industries dealing with dry bulk materials. Whether it's food products, chemicals, minerals, or raw materials, these liners offer a cost-effective solution for transporting large quantities of goods. With a growing number of Container Liners manufacturers across the globe, particularly in regions like India, companies can access high-quality products tailored to meet specific shipping needs. In fact, container liner sheet in India is widely regarded for its affordability and durability, making it a popular choice for global shipping requirements.

What Are Container Liners?

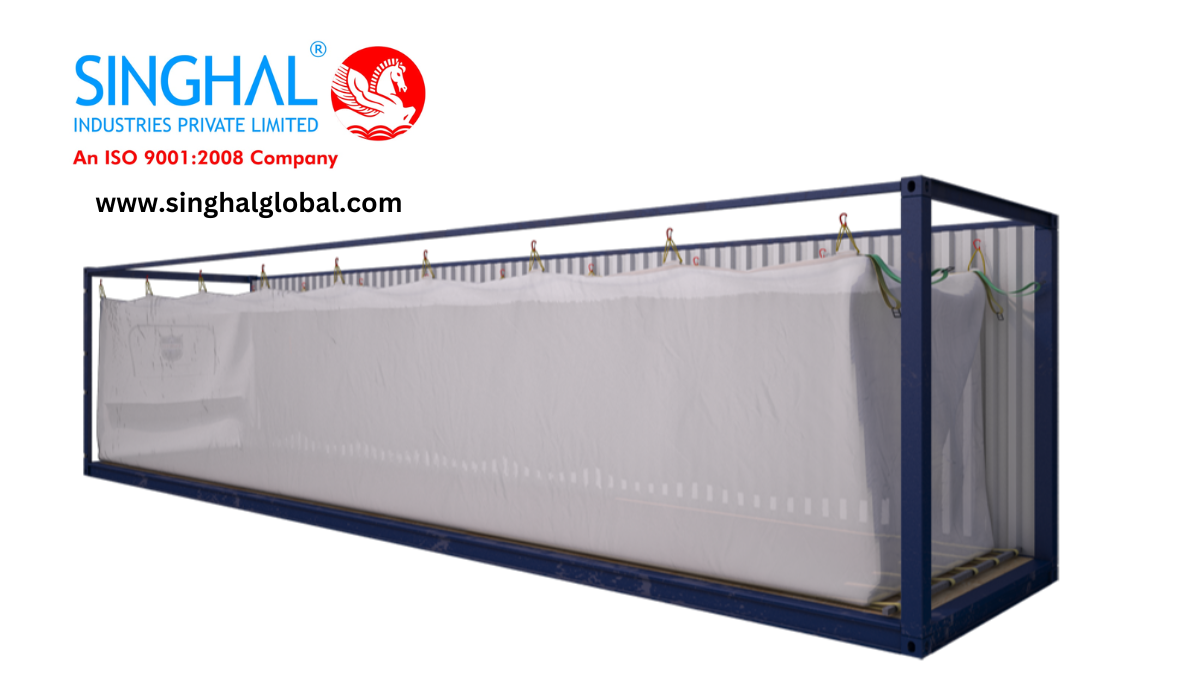

Container liners are large bags or sheets designed to fit inside standard shipping containers (20ft, 40ft, etc.). They serve as a barrier that protects bulk cargo from exposure to contaminants, moisture, and container walls, ensuring that the material stays clean and safe during transport. These liners are typically made from high-density polyethylene (HDPE) or polypropylene (PP) and come in various designs, depending on the type of material being shipped.

There are different types of container liners based on the application, including:

- Dry Bulk Liners: Designed for dry bulk cargo such as grains, chemicals, and powders.

- Liquid Bulk Liners: These are used for transporting non-hazardous liquids, such as oils and syrups.

- Thermal Liners: Used to maintain temperature control for sensitive products.

Key Features and Benefits of Container Liners

-

Cost-Effective: Container liners eliminate the need for intermediate packaging like pallets, crates, or smaller bags, thus reducing overall shipping costs. They maximize the container’s capacity, making them a highly efficient bulk transport solution.

-

Protects Cargo from Contamination: These liners create a protective barrier between the cargo and the container. This prevents any direct contact with container walls, which may have traces of dirt, moisture, or chemical residues from previous loads.

-

Prevents Moisture Damage: Many products, especially food grains and chemicals, are highly sensitive to moisture. Container liners prevent the ingress of moisture, thus ensuring that the cargo remains dry and safe during transit.

-

Versatile Applications: Container liners are suitable for various industries. They are used for transporting agricultural products (grains, seeds, etc.), chemicals, minerals, food products, and even pharmaceutical ingredients.

-

Easy Installation and Removal: Container liners are lightweight and can be easily installed in containers within a short time. After reaching the destination, they can be quickly removed without much hassle, speeding up loading and unloading processes.

-

Customizable: Many Container Liners manufacturers offer customization options. Liners can be tailored in terms of size, material, and specific features like anti-static coatings or additional barriers for moisture control.

Applications of Container Liners

-

Agriculture: Container liners are widely used for transporting agricultural products such as grains, cereals, pulses, and animal feed. The liner ensures that the products remain dry and uncontaminated during the shipping process.

-

Chemicals: In the chemical industry, where bulk powders, resins, and even hazardous materials are transported, container liners offer a secure and contamination-free shipping solution. They also help avoid spillage and product loss during transit.

-

Food Industry: For companies in the food industry, container liners are essential for transporting bulk quantities of sugar, flour, rice, and other food ingredients. The liners help ensure that food remains clean, free from pests, and unaffected by changes in temperature or humidity.

-

Pharmaceuticals: Container liners are used in pharmaceutical industries for the safe and sanitary transport of bulk pharmaceutical ingredients. This is critical to maintaining the quality and purity of sensitive materials.

-

Construction Materials: Bulk quantities of materials such as cement, sand, or minerals are often transported using container liners, ensuring that the materials remain dry and are efficiently loaded and unloaded.

Container Liners in India

India is one of the leading suppliers of container liners, producing high-quality, durable, and cost-effective liners for the global market. With a robust manufacturing base, Container liner sheet in India is known for its ability to withstand the rigors of bulk transportation, particularly in harsh environments.

Many Container Liners manufacturers in India provide customizable solutions that cater to specific industry needs. They produce liners in various designs, such as with loading spouts, discharge spouts, or thermal insulation, to ensure that goods are transported in optimal conditions. India’s container liner industry is also known for its competitive pricing, making it a leading exporter of these products.

Why Choose Container Liners?

When it comes to bulk transportation, Container Liners offer a reliable, safe, and efficient solution. They are suitable for a wide range of materials, from food products to chemicals, and they protect cargo from contamination, moisture, and external factors. The ability to customize liners to meet specific needs ensures that businesses can find the right liner solution for their unique requirements.

Choosing container liners from Container Liners manufacturer in India ensures access to high-quality products at competitive prices, making it an attractive option for businesses both domestically and internationally.

Summary

Container Liners are an essential part of modern bulk transportation, offering protection and efficiency in the shipping of a wide range of materials. Whether you’re in the agriculture, food, or chemical industry, these liners provide a cost-effective solution that maximizes cargo space and protects against contamination. With India emerging as a leading producer of container liner sheet in India, businesses can access top-quality liners that meet their shipping requirements.

FAQs

1. How are container liners installed in shipping containers?

Container liners are lightweight and can be easily installed by attaching them to the container’s walls using straps or hooks. Depending on the type of liner, loading and unloading points are strategically placed for efficient use.

2. What materials are container liners made from?

Container liners are typically made from high-density polyethylene (HDPE) or polypropylene (PP). These materials are durable, moisture-resistant, and provide protection against contamination.

3. Can container liners be reused?

In most cases, container liners are designed for single-use to ensure the cleanliness and safety of each cargo load. However, depending on the material and condition, some liners may be reusable with proper care and cleaning.