Another significant characteristic of CCW is its capacity to integrate and configure a large number of devices. The software can program and configure a wide range of Rockwell Automation devices, including Micro810, Micro820, Micro830, Micro850, and Micro870 controllers, as well as PowerFlex 4, 520-series, and 750-series drives. Because users can install, operate, and maintain these devices from a single environment, system design is simplified and fewer programming tools are needed. A further level of efficiency and integration is provided by the ability to manage PanelView 800 graphic terminals from the same software environment, which makes it easier for the controller and HMI to communicate.

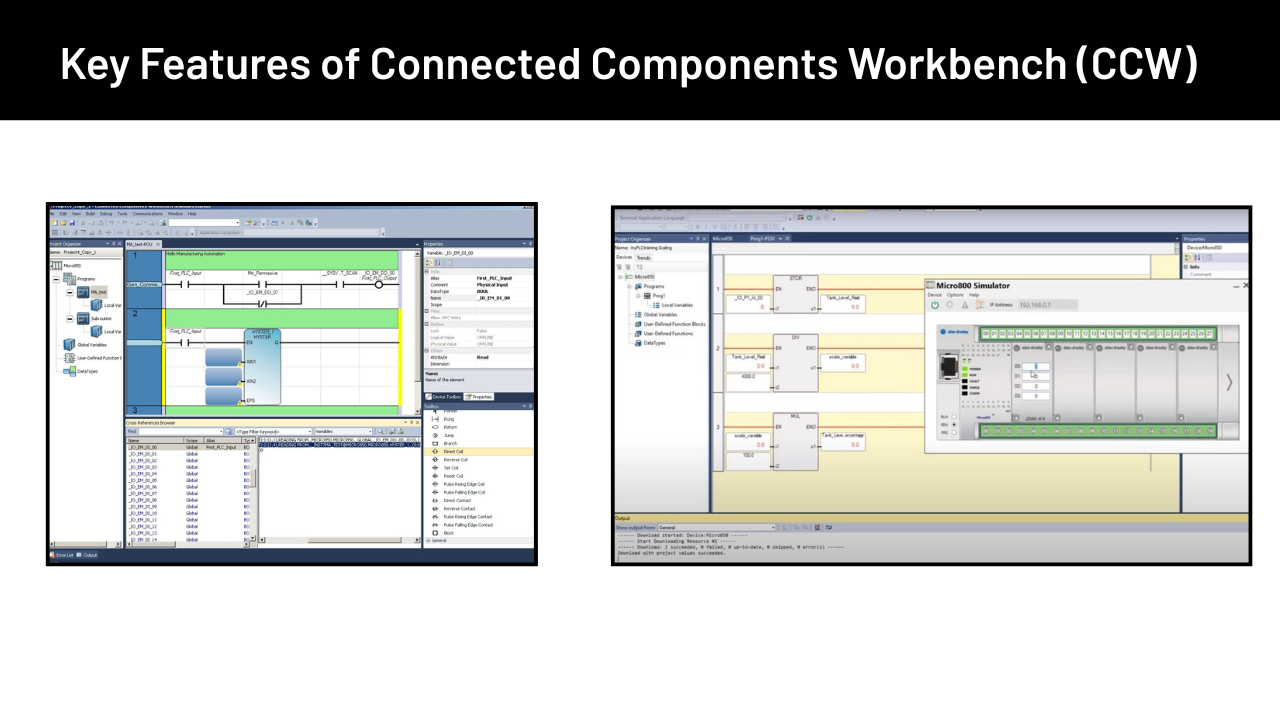

Furthermore, CCW is a pioneer in controller programming support, offering a large selection of programming languages that adhere to the IEC 61131-3 standard, such as function blocks and ladder diagrams (LD). This flexibility allows programmers to work in the language of their choice or select the one that is most appropriate for a certain application. Additionally, user-defined function blocks, complex instruction sets, and reusable code components offer the scalability and control needed for both simple and complex automated jobs. Furthermore, CCW offers diagnostic features like watch windows, breakpoints, and tag monitoring that facilitate real-time troubleshooting, reduce system downtime, and speed up commissioning.

Another significant feature of Connected Components Workbench is its integrated testing and simulation capabilities. The application allows users to reproduce controller logic without requiring a hardware connection. This virtual environment helps with performance enhancement, problem discovery, and logic validation before deployment. The offline simulation environment is also a useful tool for improving team skill development and project deadlines since it makes the first stages of training and development easier. CCW's integrated firmware update management further simplifies device maintenance by ensuring that connected components are always running the latest, secure firmware versions.

The application has robust networking and communication facilities, including built-in Ethernet and serial port configuration wizards. These make it easier for users and controls, drives, and HMIs to communicate effectively. The Auto-Discover function helps to automatically detect connected devices, which further reduces the time needed for manual setup. CCW also makes trending, recipe management, and data recording easier, enabling users to monitor performance, optimize workflows, and support flexible production environments.

One of CCW's most noteworthy characteristics is its support for global project creation, which includes a bilingual interface and support for user-generated material. This facilitates worldwide deployment and collaboration for teams spread across several locations. The application also makes it easier to communicate with Studio 5000 and Logix systems through data exchange and project import features, which is particularly useful for clients switching from smaller to bigger automation systems.

Data security and protection are also crucial elements of CCW's feature set. Features like project encryption, password security, and user access control help ensure that intellectual property is safeguarded and that only authorized personnel may upload to hardware or alter configurations. Version control and automated project backups are also made feasible by CCW, which helps teams manage changes more effectively and quickly fix problems.

Lastly, Connected Components Workbench is continuously updated to support new hardware, provide bug fixes, and enhance user functionality. Rockwell Automation also offers a free Standard Edition of the software, making it accessible for small-to-mid-sized operations, educational institutions, and developers who want to explore automation solutions without significant upfront investment. The Developer Edition includes added features like advanced drive configuration and secure programming options, catering to more complex industrial automation needs.

In conclusion, Connected Components Workbench stands out as a comprehensive, scalable, and user-friendly software platform that brings together configuration, programming, simulation, and diagnostics for a wide range of Rockwell Automation products. With its streamlined interface, multi-device support, flexible programming options, and powerful testing tools, CCW helps OEMs, machine builders, and system integrators accelerate design, reduce cost, and improve operational efficiency. Whether you're building a simple standalone machine or preparing for future system expansion, CCW provides the flexibility and performance needed to succeed in today’s industrial automation landscape.