Steel pipe cooling beds play a crucial role in the steel manufacturing process, ensuring efficient cooling and straightening of pipes. These beds are designed to handle high-temperature steel pipes, providing controlled cooling to enhance their structural integrity and quality. By utilizing advanced cooling techniques, steel pipe cooling beds contribute to the overall productivity and quality standards of the manufacturing industry. Understanding the significance of these cooling beds is essential for optimizing production processes and meeting industry demands.

Overview of Steel Pipe Cooling Beds

Definition

Steel pipe cooling beds are specialized equipment utilized in the steel manufacturing process. They play a crucial role in managing the temperature of steel pipes after fabrication.

These beds are designed to facilitate the controlled cooling of steel pipes, ensuring that they reach the desired temperature for further processing. The cooling process is essential as it helps in enhancing the structural integrity and properties of the steel pipes.

Designs and Configurations

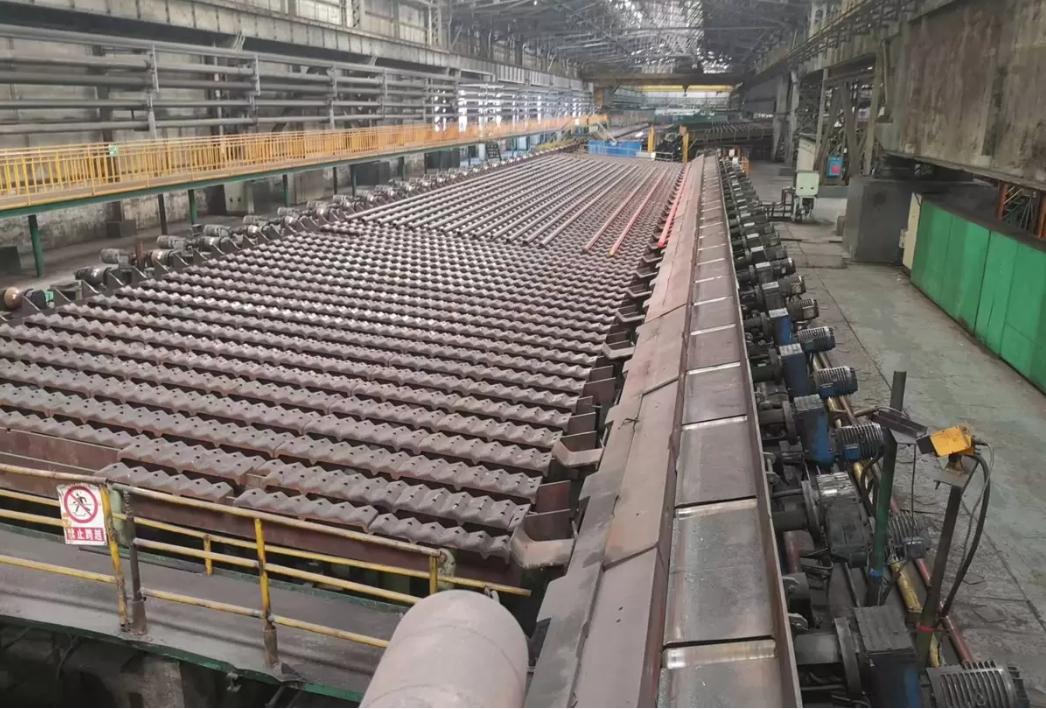

Steel pipe cooling beds come in various designs and configurations, tailored to meet different production needs. These designs may include roller-type beds, chain-type beds, or walking beam beds.

- Roller-type beds: Consist of rollers that support the steel pipes as they move along the bed, allowing for uniform cooling.

- Chain-type beds: Utilize chains to transport the steel pipes through the cooling process, offering flexibility in handling different pipe sizes.

- Walking beam beds: Employ a walking beam mechanism to move the steel pipes, providing precise control over the cooling duration.

Each design offers unique advantages based on factors such as production volume, pipe dimensions, and required cooling rates. Manufacturers can choose the most suitable design based on their specific requirements.

Steel pipe cooling beds are integral to ensuring that steel pipes achieve optimal properties through controlled cooling post-fabrication. By utilizing these specialized equipment, manufacturers can enhance the quality and durability of their steel products, meeting industry standards and customer expectations effectively.

Functioning of Cooling Beds

Utilizing Gravity

Cooling beds leverage gravity to allow steel pipes to move smoothly along the bed. As the hot pipes exit the furnace, they are transferred onto the cooling bed through a series of rollers. This movement is facilitated by the force of gravity, ensuring a continuous and efficient cooling process.

Airflow Mechanism

The cooling process on these beds is enhanced by an effective airflow mechanism. As the steel pipes travel along the bed, they are exposed to a controlled flow of air that aids in dissipating heat rapidly. This airflow helps maintain a consistent cooling rate, ensuring uniform temperature reduction across all pipes.

Sequential Operations

After exiting the furnace, steel pipes follow a specific sequence of operations before reaching the cooling bed. They pass through various stages such as straighteners and water spray systems to prepare them for the cooling process. Once on the bed, the pipes are strategically positioned to optimize airflow around them, facilitating efficient cooling.

Timing and Temperature Control

Precise timing and temperature control are critical factors in the efficiency of the cooling process. Maintaining optimal temperatures and ensuring that pipes spend the right amount of time on the cooling bed are essential for achieving desired metallurgical properties. Deviations in timing or temperature can result in uneven cooling, affecting the quality of the final product.

Importance of Uniform Cooling

Consistent Cooling

Steel pipe cooling beds play a crucial role in ensuring proper cooling rates for the pipes. It is essential to maintain efficient cooling to achieve the desired properties in the final product.

Preventing Thermal Stress

Rapid cooling must be uniform across all surfaces of the pipe to prevent thermal stress. Inconsistent cooling can lead to internal stresses, affecting the structural integrity of the steel pipes.

Enhancing Product Quality

Uniform cooling is vital for enhancing the quality of steel pipes. It helps in achieving the desired mechanical properties and dimensional accuracy. Heat input during the cooling process must be controlled to avoid any defects in the final product.

Steel pipes subjected to non-uniform cooling may experience distortion, warping, or even cracking. By ensuring uniform cooling rates, manufacturers can produce high-quality steel pipes that meet industry standards.

- Pros:

- Improved product quality

- Reduced chances of defects

Maintaining consistent cooling rates throughout the entire length of the steel pipe is critical for meeting performance requirements. It influences factors such as hardness, strength, and ductility, which are essential for various applications in construction, oil and gas, and other industries.

Preventing Warping in Steel Pipes

Cooling Bed Methods

Steel pipe cooling beds employ various methods to prevent warping during the cooling process. These beds are designed to ensure that steel pipes cool uniformly, reducing the risk of distortion. By utilizing controlled cooling rates and mechanisms such as water sprays or air jets, these beds help maintain the straightness of the pipes.

Controlled Cooling for Shape Maintenance

Controlled cooling is crucial in maintaining the original shape of steel pipes after the welding process. As steel pipes cool down, internal stresses can cause them to warp or distort. Through controlled cooling on specialized beds, the heat distribution within the pipes is regulated, allowing them to cool evenly and minimizing the risk of warping.

Impact on Downstream Processes

Warping in steel pipes can have a significant impact on downstream processes and the usability of the final product. When pipes warp during cooling, it can lead to dimensional inaccuracies and affect the overall quality of the weld metal. This can result in challenges during subsequent processes such as pipe fitting and installation.

Understanding Distortion During Fabrication

Types of Distortion

Steel pipe cooling beds play a crucial role in the manufacturing process of steel pipes. Deformation is a common issue that can occur during fabrication, leading to variations in the pipe's dimensions. Two primary types of distortion are angular distortion and longitudinal distortion. Angular distortion causes the pipe to bend or twist, while longitudinal distortion affects the pipe's length.

Angular distortion can result from uneven cooling rates across the pipe, leading to production inefficiency and structural weaknesses. On the other hand, longitudinal distortion often occurs due to internal stresses within the material, causing the pipe to elongate or shorten unevenly.

Factors Contributing to Distortion

Several factors contribute to distortion during the fabrication of steel pipes. Temperature gradients within the pipe play a significant role in causing deformation. Variations in cooling rates along the length of the pipe can result in non-uniform contraction, leading to angular or longitudinal distortion. Material properties such as composition, grain structure, and residual stresses can influence the extent of distortion experienced during fabrication.

Addressing Distortion Early

Addressing distortion early in the manufacturing process is crucial for ensuring product quality and production efficiency. By implementing proper cooling strategies and monitoring temperature gradients during cooling, manufacturers can minimize the risk of distortion in steel pipes. Early detection and correction of deformation issues can help prevent costly rework and ensure that the final products meet dimensional tolerances and structural requirements.

Benefits of Using Cooling Beds

Cost Savings

Steel pipe cooling beds offer significant cost savings by reducing waste and rework in the manufacturing process. Effective cooling minimizes distortions, leading to less material loss and lower production costs.

Production Efficiency

The design of cooling beds plays a crucial role in enhancing production efficiency. By ensuring optimized cooling times, manufacturers can increase output and meet tight deadlines more effectively.

Safety Standards

Cooling beds contribute to improved safety standards in manufacturing environments. By providing a controlled cooling process, they help prevent accidents and ensure that workers operate in a safer working environment.

Enhancing Structural Integrity

Proper Cooling for Durability

Steel pipes undergo internal stresses during manufacturing, affecting their mechanical properties. Proper solidification and cooling are crucial to alleviate these stresses.

Cooling at the right rate is essential for achieving high quality steel pipes. It helps in reducing damage caused by residual stresses.

The cooling process impacts the quality of the final product significantly. Inadequate cooling can lead to defects, compromising the overall structural integrity.

Mechanical Properties and Cooling Practices

Effective cooling practices play a vital role in enhancing the mechanical properties of steel pipes. They influence the pipe's strength, toughness, and ductility.

Proper solidification followed by controlled cooling ensures that the steel maintains its desired properties. This process prevents the formation of undesirable phases that could weaken the material.

By controlling the cooling rate, manufacturers can tailor the mechanical properties of steel pipes to meet specific requirements. This customization enhances the overall performance and longevity of the pipes.

Role of Cooling Beds in Compliance

Cooling beds are integral components in ensuring that steel pipes meet industry standards for structural integrity. These beds provide continuous support to the pipes during the cooling process.

The environment and conditions within cooling beds are carefully regulated to facilitate proper solidification and cooling. This controlled setting is crucial for maintaining the structural quality of the pipes.

Steel pipe manufacturers rely on efficient cooling systems with well-designed components to achieve optimal results. The cooling bed's design and operation play a critical role in preventing defects and ensuring consistent product formation.

Increasing Longevity of Steel Pipes

Effective Cooling Techniques

Steel pipes are crucial components in various industries, and effective cooling techniques play a vital role in enhancing their longevity. By utilizing advanced cooling methods during the manufacturing process, such as controlled cooling beds, steel pipes can achieve optimal strength and durability. This results in quality steel pipes that can withstand harsh conditions and last longer in service.

Reduced Maintenance Costs

One significant advantage of using high-quality steel pipes with extended lifespan is the reduction in maintenance costs. When steel pipes have a longer service life due to effective cooling processes, companies benefit from decreased maintenance requirements and lower replacement frequency. This leads to cost savings in terms of repairs, replacements, and overall maintenance expenses.

Environmental Benefits

The use of durable steel pipes produced through efficient cooling techniques offers environmental benefits by reducing resource consumption over time. Longer-lasting steel pipes mean fewer replacements are needed, leading to decreased material wastage and energy consumption associated with manufacturing new pipes. This contributes to sustainable practices within the steel industry and helps minimize the environmental impact of steel production.

Final Remarks

The use of cooling beds in the steel pipe industry plays a pivotal role in ensuring the quality and durability of the final product. By understanding the intricacies of uniform cooling, preventing warping, and enhancing structural integrity, manufacturers can significantly improve the longevity of steel pipes. Embracing these practices not only minimizes distortion during fabrication but also leads to a more reliable end product, meeting industry standards and customer expectations.

For those involved in the steel pipe manufacturing process, implementing effective cooling bed techniques is crucial for producing high-quality pipes that stand the test of time. Continuous improvement in cooling processes will not only enhance the overall product but also solidify a reputation for excellence within the industry. Invest in refining cooling bed practices to elevate the quality and reliability of steel pipes, setting a benchmark for others to follow.

The Role of Cooling Beds in Achieving Uniform Cooling of Steel Pipes