Understanding the Importance of Differential Shafts in Modern Machinery

A differential shaft is an essential component in many mechanical systems, ensuring the efficient transmission of rotational energy in various machinery. Used in applications ranging from automotive drivetrains to industrial equipment, differential shafts are designed to enable smooth and efficient movement in complex systems. For industries relying on high-precision equipment, partnering with a trusted Differential Shaft Supplier is crucial for maintaining optimal machinery performance.

What is a Differential Shaft?

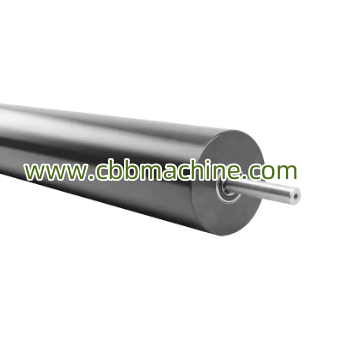

At its core, a differential shaft is a mechanical part used to transfer torque between rotating parts while allowing those parts to rotate at different speeds. This is particularly important in systems where multiple outputs are required to rotate independently, such as in gear systems or machinery that requires synchronized rotation.

In applications such as candy manufacturing, automotive engineering, and heavy machinery, differential shafts provide a means of regulating the rotational forces that drive various components, enabling them to function smoothly and effectively. Without these components, the machinery would face severe inefficiencies, leading to equipment breakdowns and production delays.

The Role of a Differential Shaft in Machinery

Differential shafts are integral to many types of machinery, particularly in industries that rely on continuous motion and precision. For example, in candy production, these shafts allow various parts of the candy-making machines—such as mixers, molders, and conveyors—to function independently while being driven by the same power source. The differential shaft ensures that power is transmitted accurately and efficiently to each part of the machine, allowing for consistent production processes and high-quality output.

In other industries, such as the automotive sector, differential shafts are crucial for transmitting power to the wheels, especially in systems where the wheels need to rotate at different speeds, such as during turns. This prevents unnecessary wear on the tires and maintains vehicle stability.

Choosing the Right Differential Shaft Supplier

When searching for a Differential Shaft Supplier, quality, durability, and customization options should be the primary factors to consider. A reputable supplier ensures that their products meet industry standards for performance and reliability, offering solutions that stand the test of time under demanding conditions.

Working with an experienced Differential Shaft Supplier can help businesses enhance their production efficiency, minimize downtime, and reduce the frequency of repairs. High-quality shafts reduce mechanical failures, which can disrupt manufacturing lines and result in costly maintenance.

It’s important to choose a supplier who can offer a broad range of differential shaft options that meet the specific needs of your machinery. Some applications may require shafts that are resistant to corrosion, while others may demand shafts that can withstand high torque or extreme temperatures. A reliable Differential Shaft Supplier will provide products that meet these specific requirements and ensure that your machinery operates at its peak.

Benefits of High-Quality Differential Shafts

Improved Efficiency: High-quality differential shafts ensure that power is transmitted effectively, improving the overall efficiency of the machinery. By reducing friction and wear, these shafts contribute to smoother operation, enhancing the productivity of your production lines.

Increased Longevity: Durable differential shafts last longer than their lower-quality counterparts, reducing the need for frequent replacements and lowering maintenance costs. A Differential Shaft Supplier who prioritizes quality can help extend the lifespan of your machinery.

Customization: Many industries have specific needs when it comes to differential shafts. Whether it's for a candy-making machine, an industrial conveyor system, or a vehicle drivetrain, a Differential Shaft Supplier can offer customizable solutions. Tailored designs can be created to ensure that the shafts meet the exact specifications of your equipment.

Reduced Downtime: By choosing a trusted supplier, businesses can reduce the likelihood of unexpected failures. This leads to fewer instances of downtime and more consistent production, which is essential for industries where time is a critical factor.

Applications of Differential Shafts

Differential shafts are used across numerous sectors, where they help manage the distribution of power between rotating components. Some common applications include:

Candy Production: Differential shafts are vital in machines that require different parts to rotate at different speeds. For example, they help power mixers, molders, and conveyors simultaneously in candy manufacturing.

Automotive Engineering: Differential shafts are integral to vehicles’ drivetrains, allowing power to be distributed efficiently to the wheels. This is especially important when turning corners, as the inner and outer wheels need to rotate at different speeds.

Heavy Machinery: In industrial machinery, differential shafts are essential for distributing torque to various moving parts, enabling precise operations in manufacturing plants and construction equipment.

Why Choose Us as Your Differential Shaft Supplier?

As a leading Differential Shaft Supplier, we pride ourselves on providing reliable, high-quality components tailored to your specific needs. Our differential shafts are designed to meet stringent industry standards and are tested for durability, efficiency, and performance.

By working with us, you benefit from:

Customization: We understand that every business has unique requirements. Our team works with you to design differential shafts that fit your machinery perfectly.

Precision: We ensure that every shaft we supply is manufactured to precise specifications, ensuring optimal performance.

Long-Term Support: Our commitment to our clients doesn’t end at the point of sale. We offer continued support and service to ensure your machinery remains in peak condition.

Conclusion

Choosing the right Differential Shaft Supplier is a crucial step toward ensuring the efficiency and longevity of your machinery. Whether you're involved in candy production, automotive manufacturing, or heavy industry, the quality of your differential shafts can make a significant difference in your operations. Investing in high-quality, customizable shafts helps you optimize production, reduce costs, and minimize downtime, making them a vital component of your business success.