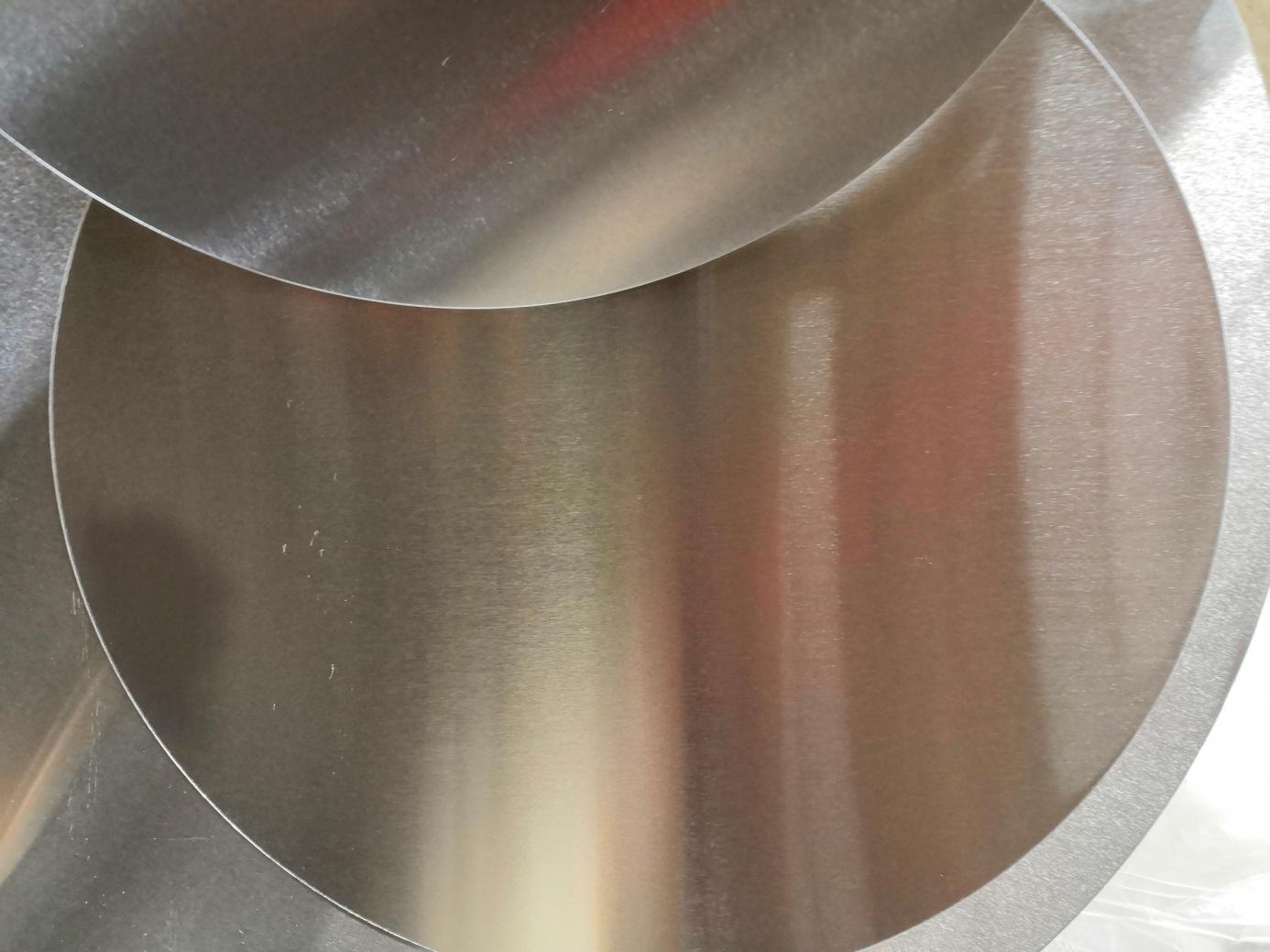

5052 aluminium round discs are of the fine performances in all normal aluminum circle alloys. The 5052 aluminum circle is an AL-Mg series alloy and is the maximum extensively used sort of rust-evidence aluminum. Because magnesium is the principle alloying detail of 5052 aluminum, the strength of 5052 is high, mainly the fatigue energy. Similarly to magnesium, different alloy factors are introduced to the 5052 aluminum wafer, which additionally contains a small amount of manganese, chromium, beryllium, titanium, and so on. In addition to a small amount of stable solution, the manganese within the alloy frequently bureaucracy MnAl6. The impact of chromium is similar to that of manganese. It improves the resistance to pressure corrosion cracking, will increase the energy of the bottom steel and the weld, and decreases the tendency of welding cracks, but its content commonly does no longer exceed zero.35%. 5052 aluminum has excessive plasticity and corrosion resistance, and can't be bolstered via warmth remedy. The plasticity is ideal at some stage in semi-bloodless paintings hardening, and the plasticity is low when bloodless paintings hardening, which may be polished.The thickness of 5052 aluminum discs is from 0.5mm to six.0mm. We supply tempers of O, H12, H22, H14, H24, H32 and so forth. The diameter stages among 100mm and 1300mm, but on the whole from 200mm to 800mm. The discs are low in density, mild in weight, accurate in tensile power, strong in fatigue capacity, high in crystal particle and smooth in surface. Used in excessive give up cooking utensils like pressure boxes and non-stick cookers, 5052 aluminum discs clean can be similarly processed by using anodizing, PVDF coating, PE coating and so on. We've got anodized aluminum circles, and our coating traces are beneath coaching. There may be no question that we are able to be capable of deliver pre-painted aluminum discs quickly.