For the purpose of conducting research on rock fracturing and acidizing processes, a rock fracturing and acidizing drilling and well control simulators is either a piece of hardware or a piece of software that is utilized for the purpose of simulating those processes in order to carry out research on those processes. Both of these categories of simulators are referred to collectively by the term "fracturing and acidizing simulator," which is a term that describes both of these categories. It begins by simulating the essential processes and parameters of acidizing and fracturing operations, and then it moves on to evaluating the impact and effect that these procedures have on the subsurface reservoirs or wellbores. This step comes after the simulation of the essential processes and parameters of acidizing and fracturing operations. By carrying it out in this way, it is possible to accomplish the goal that was stated earlier.

In order to generate fractures and increase the permeability of the reservoir, a technique that is known as hydraulic fracturing involves injecting fluid into a wellbore while the fluid is under high pressure. Because of this, the reservoir is able to accommodate a greater volume of fluid. As a consequence of this, the reservoir has the capacity to store a greater quantity of liquid. On the other hand, acidizing is the process of treating the wellbore and the reservoir formations with acid fluids in order to remove sediment and increase flow capacity. This is done in order to maximize production from the reservoir. This is done so that production can be increased to its full potential. This is done in order to maximize the output of the production and reach its full potential. Both of these recent technological advances are put to extensive use in the process of extracting oil and gas, which contributes to an increase in production as well as an improvement in overall productivity.

What are the benefits and advantages of using the drilling and well control simulators for acidizing and fracturing, as well as what are the features of this simulator and what are the characteristics of this simulator? In addition, what are the features of this simulator?

The drilling and well control simulators for fracturing and acidizing possesses, in addition to the benefits that are described in greater detail in the following paragraphs, the qualities that are detailed in the following paragraphs:

1. A high level of controllability: the simulator for hydraulic fracturing and acidizing has the ability to accurately control and adjust a wide variety of parameters and conditions. This is one of the most important features of the simulator. This is one of the most essential components of the drilling and well control simulators that you can use. This category encompasses a wide range of topics, some of which are the injection pressure, flow rate, rock properties, fluid properties, and so on. Because of this, the drilling and well control simulators is able to simulate a wide variety of real-world operating scenarios and evaluate the impact that a wide variety of parameters have on both yield and performance. In addition, the simulator can simulate a wide variety of performance and yield metrics. In addition to this, the is able to model a broad spectrum of performance and yield metrics.

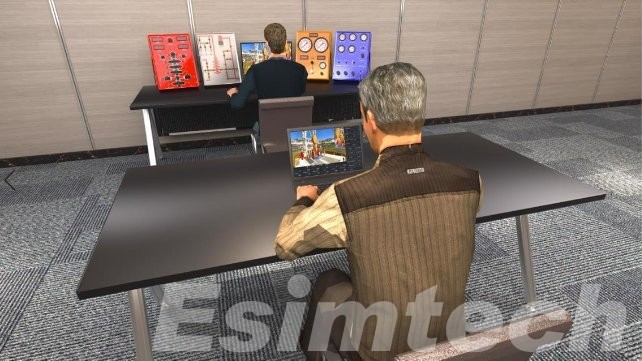

2. Virtual LaboratoryThe simulator is equipped with a virtual laboratory that makes it possible to carry out a variety of trials and tests in either a computer model or a physical model. This feature makes it possible to investigate and improve the procedure for fracturing and acidizing the rock. This can be done in order to simulate conditions that exist in the real world. This is something that can be done in order to conduct research and come up with new methods for the process, and it is something that can be done. Not only does this result in a significant reduction of the costs associated with conducting actual trials, but it also results in a significant reduction of the risks that are associated with doing so.

3. Prediction in multiple dimensions: The simulator enables the prediction and evaluation of multiple indicators, such as fracture expansion, fluid distribution, production prediction, and recovery factor, amongst others. This feature enables the prediction and evaluation of multiple indicators. Because of this, it is possible to produce an accurate evaluation of the performance of the well. Because of this, it is now possible to generate predictions regarding the growth of an oil or gas field that can be relied upon. Engineers and researchers can make use of this information to acquire a more in-depth understanding of the outcomes of jobs, improve the efficiency of designs and decisions, and forecast the financial outcomes of projects.

4. Achieving the highest possible level of effectiveness in one's own designs and scenariosThe use of simulators for acidizing and fracturing can be helpful in optimizing designs for acidizing and fracturing by comparing the effects of a number of different parameters, scenarios, and approaches. This can help designers create designs that are more effective for acidizing and fracturing. Because of this, designers may find it easier to create designs that work well with acidizing and fracturing. Simulation and analysis are both helpful tools in this endeavor, and they can be used together to derive the parameter settings that produce the best possible results for an operation. This has the potential to significantly cut down on the amount of time and money that is spent on experimentation, in addition to eliminating any unnecessary risks that may be involved.

The drilling and well control simulators for fracturing and acidizing has many benefits, some of which are listed below: high controllability; a virtual laboratory; multi-dimensional prediction; optimal design; education and training; and other benefits. In addition to this, the can be utilized to gain a deeper comprehension of the procedure. They make available highly efficient tools for research, optimization, and training, all of which contribute to an increase in the overall productivity, safety, and profitability of acidizing and fracturing operations.