BOPP Bags Modern Packaging Solutions

BOPP bags have revolutionized the packaging industry due to their superior strength, excellent clarity, and high durability. These bags, made from Biaxially Oriented Polypropylene (BOPP), offer a unique combination of flexibility and toughness, making them a preferred choice for packaging various products. Industries such as food, agriculture, textiles, and consumer goods rely heavily on these bags for secure storage and transportation. With the demand for high-quality packaging materials increasing, manufacturers and suppliers are continually innovating to enhance the performance of Bopp Bag Exporters in Gujarat Many businesses seeking efficient packaging solutions turn to reliable sources for high-grade materials that meet industry standards. Their widespread use is a testament to their effectiveness in maintaining product integrity and extending shelf life.

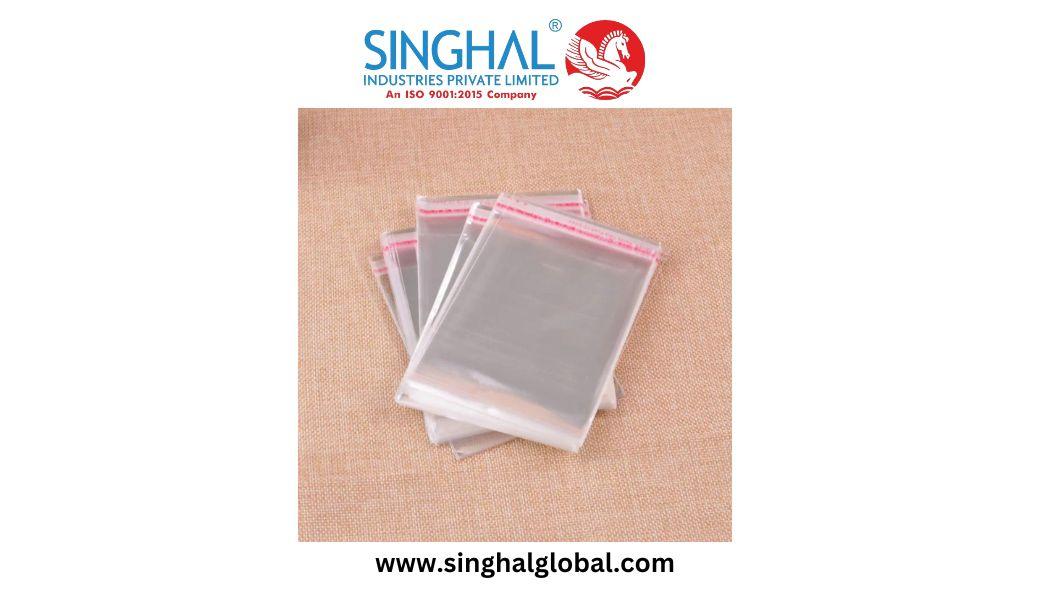

Key Features That Make These Bags a Popular Choice

BOPP bags offer numerous advantages over traditional packaging materials. Their high tensile strength makes them resistant to tearing, ensuring the safe transportation of goods. They are also moisture-resistant, protecting products from humidity and external contaminants. One of the standout features of these bags is their excellent printability, allowing businesses to create visually appealing packaging with vibrant designs and branding elements. The transparency of BOPP material enhances product visibility, providing consumers with a clear view of the contents inside. Additionally, these bags are lightweight, reducing shipping costs while maintaining the robustness needed for handling heavy loads. Businesses looking for premium packaging solutions often collaborate with trusted industry professionals to ensure they receive high-quality materials suitable for their specific needs.

Common Applications Across Various Industries

The versatility of BOPP bags makes them suitable for multiple industries, each utilizing them for distinct purposes. In the food industry, they are used to package grains, pulses, snacks, and bakery items, providing a barrier against moisture and contamination. The agricultural sector relies on these bags for storing fertilizers, seeds, and animal feed, ensuring the safe handling of bulk materials. Textile businesses use them for packaging garments, offering protection against dust and damage during transit. Retail stores prefer these bags for their aesthetic appeal and reusability, making them an eco-friendly alternative to conventional plastic packaging. With the growing demand for efficient and sustainable packaging solutions, suppliers in the industry continuously work on enhancing the functionality and appeal of these bags to meet diverse market needs.

Why the Manufacturing Process Matters

The production of BOPP bags involves advanced technology and stringent quality control measures to ensure consistency and reliability. The biaxial orientation process enhances the strength and clarity of the material, giving the bags their signature and durability. High-quality raw materials are used to maintain superior mechanical properties, ensuring resistance to punctures and abrasions. Advanced printing techniques allow for custom branding, transforming ordinary bags into effective marketing tools. The thickness and sealing process plays a crucial role in determining the bag's overall performance, ensuring that the contents remain secure during transportation and storage. Reliable manufacturers focus on innovation, incorporating new techniques to enhance the efficiency and sustainability of their packaging solutions to cater to various industry requirements.

How Businesses Benefit from Using High-Quality Packaging

Investing in premium packaging materials provides businesses with multiple advantages beyond just product protection. Visually appealing and well-designed packaging enhances brand recognition and customer perception, giving companies a competitive edge in the market. High-strength materials reduce product loss due to damage during shipping, leading to lower replacement costs and improved profitability. The lightweight nature of Bopp Bags Supplier in Ahmedabad minimizes transportation expenses, making them an economical choice for bulk shipments. Customization options allow businesses to tailor their packaging to reflect their brand identity, helping them stand out on store shelves. By working with experienced suppliers, businesses can access innovative packaging solutions that align with their operational needs and sustainability goals, ultimately improving overall efficiency and customer satisfaction.

The Role of Reliable Suppliers in Meeting Industry Demands

Quality packaging solutions depend on the expertise and reliability of suppliers who understand the evolving needs of businesses. Trusted suppliers provide customized solutions that cater to various industries, ensuring that clients receive the best-suited materials for their specific applications. They offer a range of options, from standard clear bags to printed and laminated variations, providing businesses with flexibility in their packaging choices. Many suppliers focus on sustainable production practices, incorporating recyclable materials and eco-friendly processes to reduce environmental impact. Collaborating with reputable professionals ensures consistent product quality, timely delivery, and compliance with industry regulations. This strategic partnership helps businesses streamline their packaging operations, ensuring that they meet both functional and branding requirements efficiently.

Challenges Faced in the Packaging Industry and Their Solutions

Despite their numerous advantages, the packaging industry faces several challenges, including environmental concerns, fluctuating raw material prices, and the need for innovation to keep up with market trends. The push for sustainable packaging has led to the development of biodegradable and recyclable alternatives, addressing environmental concerns while maintaining product performance. Advances in material science have allowed manufacturers to create thinner yet stronger films, reducing material usage without compromising durability. Price volatility in raw materials has led to the exploration of cost-effective alternatives that maintain quality while minimizing production costs. Continuous research and development ensure that packaging solutions remain adaptable to changing consumer demands, ensuring long-term viability and sustainability in the industry.

Future Trends and Innovations in the Packaging Sector

The future of packaging is driven by technological advancements and increasing consumer awareness of sustainability. Smart packaging solutions, including QR codes and embedded tracking systems, are gaining traction, allowing businesses to improve logistics and consumer engagement. The demand for biodegradable and compostable materials is expected to grow as industries seek environmentally responsible alternatives. Advances in printing technology enable higher-quality graphics and branding opportunities, enhancing the overall appeal of packaged products. Digitalization in supply chain management is improving efficiency and reducing lead times, ensuring that businesses can adapt to market changes more effectively. Companies that embrace these trends and invest in innovative packaging solutions will remain competitive, meeting both regulatory standards and consumer expectations for sustainability and functionality.

Conclusion

BOPP bags have established themselves as an essential component of modern packaging solutions, offering strength, clarity, and customization options that cater to various industries. Their widespread use in food, agriculture, textiles, and retail demonstrates their adaptability and effectiveness in preserving product quality. The manufacturing process plays a crucial role in ensuring that these bags meet industry standards, providing businesses with reliable packaging solutions. Companies that prioritize high-quality packaging benefit from enhanced brand recognition, reduced shipping costs, and improved product protection Bopp Bag Manufacturer in Ahmedabad continues to evolve, embracing new technologies and sustainable practices will be key to staying ahead of market trends and meeting consumer demands for environmentally responsible packaging solutions.

Frequently Asked Questions

What makes BOPP bags different from regular plastic bags?

BOPP bags are made using biaxially oriented polypropylene, which enhances their strength, clarity, and durability. Unlike standard plastic bags, they offer superior printability, moisture resistance, and better protection for packaged goods, making them an ideal choice for various industries.

Can these bags be customized for branding purposes?

Yes, BOPP bags are highly customizable, allowing businesses to incorporate branding elements such as logos, colors, and product information. Advanced printing techniques ensure that graphics remain vibrant and resistant to fading, helping businesses enhance their brand visibility.

Are BOPP bags environmentally friendly?

Many BOPP bags are designed to be recyclable, contributing to environmental sustainability. Manufacturers are also exploring biodegradable alternatives to reduce plastic waste, aligning with global efforts to promote eco-friendly packaging solutions.

Where can businesses source high-quality BOPP bags?

Companies looking for premium packaging solutions can collaborate with trusted professionals in the industry. Working with reputable suppliers ensures access to high-quality materials that meet industry standards, providing businesses with reliable and efficient packaging options.