In today's fast-paced commercial landscape, packaging solutions must evolve to meet the growing demands for durability, aesthetic appeal, and sustainability. PP corrugated sheets, made from polypropylene, have emerged as a popular choice across various industries for their distinctive properties and functionalities. Due to their lightweight nature and robust structure, these sheets are widely adopted for packaging, signage, and even construction applications. This Pulkit Plastic Products explores the characteristics, manufacturing processes, benefits, and extensive applications of corrugated plastic sheets, providing insights into why they have become a preferred material in many sectors.

Understanding PP Corrugated Sheets

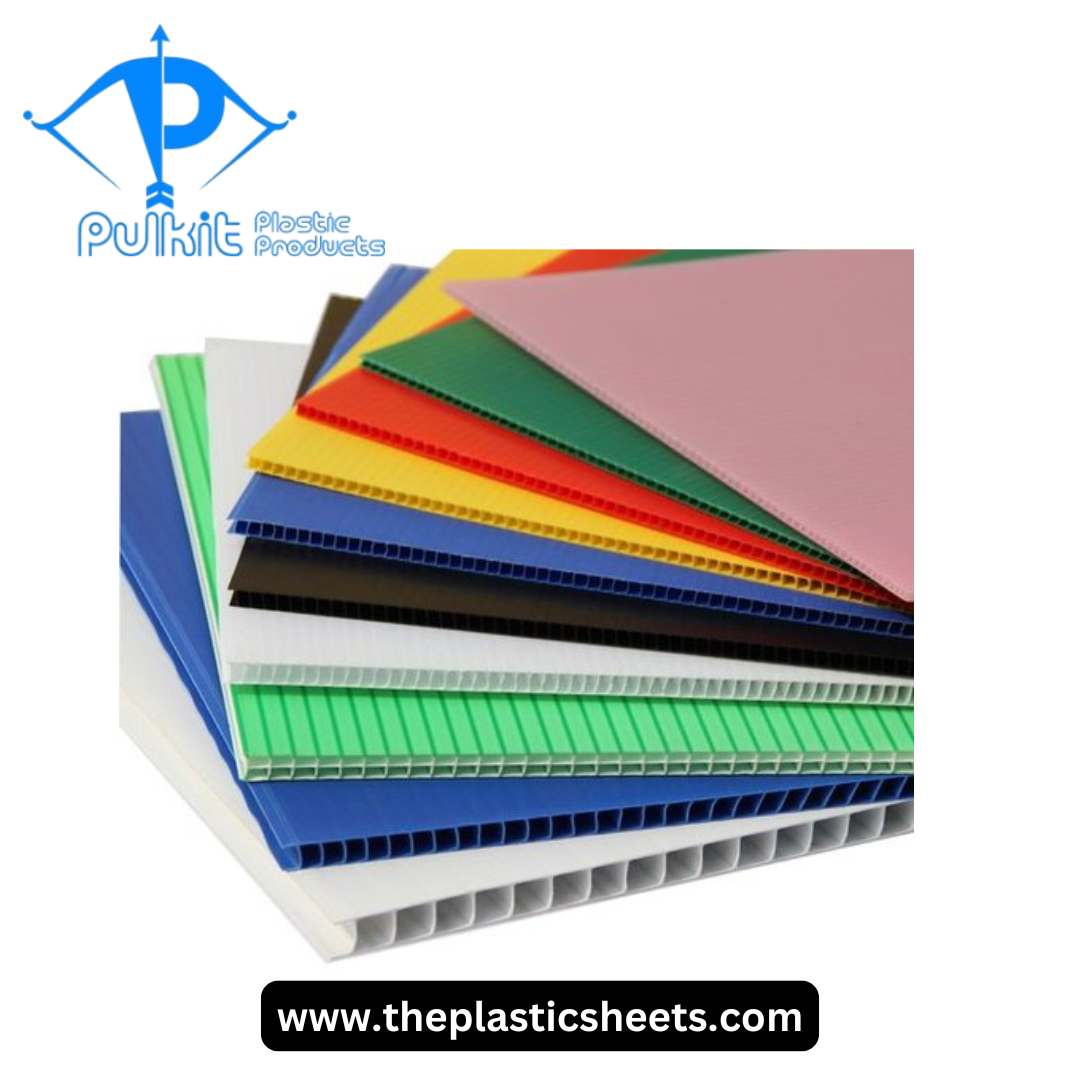

PP corrugated sheets, or corrugated plastic sheets, are multi-layered structures characterized by their wavy, fluted design sandwiched between two flat layers. This unique design not only enhances their strength but also makes them lightweight, providing a significant advantage over traditional materials like cardboard or wood. These sheets are produced through a process that involves the extrusion of polypropylene, resulting in a robust yet flexible sheet material that can withstand various stresses without sacrificing performance.

The manufacturing process of corrugated plastic sheets involves heating polypropylene pellets until they melt, then extruding the molten material through a die to form the corrugated structure. After cooling, the sheets can be cut to specific dimensions, embossed with designs, or laminated for added protection or aesthetics. Given their ease of customization, they can be tailored to meet specific industry needs, making them a versatile choice for many applications.

Advantages of Corrugated Plastic Sheets

One of the standout features of Corrugated plastic sheet Manufacturers is their exceptional durability. Resistant to moisture, chemicals, and UV rays, these sheets can withstand adverse environmental conditions, making them suitable for both indoor and outdoor applications. This resilience provides businesses with a reliable solution for packaging and displays, ensuring that products remain protected during transportation and storage.

In addition to their durability, corrugated plastic sheets are also remarkably lightweight. This characteristic not only reduces shipping costs but also simplifies handling and installation. Businesses can save time and resources by using lighter materials without compromising strength and functionality. Additionally, the flexibility of the material allows it to be cut, folded, or shaped easily, making it ideal for a variety of project requirements.

Environmental Sustainability

As global environmental concerns rise, companies are increasingly looking for sustainable materials to use in their operations. Many corrugated plastic sheet manufacturers are responding to this demand by producing sheets from recycled materials or ensuring that their products are fully recyclable. Polypropylene itself is a type of plastic that can be recycled multiple times, reducing waste and contributing to a circular economy.

Using corrugated plastic sheets also minimizes waste during manufacturing and end-of-life disposal compared to traditional materials. For instance, they produce less scrap during their production process, and their lightweight nature reduces carbon emissions associated with transport. By choosing environmentally friendly options, businesses can enhance their sustainability credentials while also appealing to eco-conscious consumers.

Applications Across Various Industries

The versatility of PP corrugated sheets lends itself to a broad range of applications across numerous industries. In the packaging sector, these sheets provide an excellent alternative to cardboard boxes, especially for products that require added strength and moisture resistance. Their durability makes them ideal for shipping everything from electronics to food products, allowing for safe and secure transportation.

In the signage industry, corrugated plastic sheets are often used for temporary and permanent displays. Their lightweight nature facilitates easy installation for point-of-sale displays, directional signs, and advertising boards, making them a go-to choice for businesses looking to grab attention without overwhelming costs. Additionally, they can be printed with vibrant colors and designs, allowing companies to convey branding messages effectively.

The construction industry also benefits significantly from the use of corrugated plastic sheets. They can serve as lightweight barriers, protective coverings, or even temporary walls on construction sites. Their ability to endure harsh weather conditions while protecting other materials makes them invaluable in maintaining safety and organization on-site.

A Growing Market of Manufacturers

The demand for corrugated plastic sheets has led to an increase in manufacturers specializing in this material. As competition grows, Corrugated plastic sheet are consistently innovating to enhance the quality, performance, and sustainability of their products. This ongoing innovation has expanded the range of available options, from different thicknesses and textures to a variety of colors, catering to the unique requirements of diverse industries.

Furthermore, advancements in technology and production methods have streamlined the manufacturing process, resulting in cost-effective solutions for end-users. Many manufacturers also offer customization options, allowing businesses to order sheets tailored to their specific dimensions and durability needs. This adaptability has made it easier for companies to incorporate corrugated plastic sheets into their operations seamlessly.

Durability and Maintenance

One of the most appealing attributes of PP corrugated sheets is their low maintenance requirements. Unlike wood or certain other materials, corrugated plastic sheets do not require treatments or chemicals to protect against rot or pests. This easy-care aspect allows businesses to focus on their core operations without worrying about product care. A simple wash with soap and water is often sufficient to keep them clean and visually appealing.

While the sheets are designed to be durable, it is essential to recognize that they have limitations. Extreme temperatures, physical impacts, or prolonged exposure to ultraviolet light can compromise their integrity over time. Therefore, businesses should consider the conditions in which they will be using these sheets and select the appropriate thickness and type that caters to their specific needs.

Conclusion

PP corrugated sheets have established themselves as an essential material in various industries, thanks to their unique combination of durability, lightweight properties, and versatility. As businesses continue to seek sustainable and cost-effective solutions for packaging, display, and construction, these sheets provide an ideal option. The ongoing innovations from corrugated plastic sheet manufacturers ensure that this material will continue to evolve to meet the demands of modern applications.

By choosing Corrugated plastic sheets, companies not only gain access to a reliable and effective material but also contribute to a more sustainable future. Their applications span multiple sectors, showcasing the capability of this remarkable material to support various industries while addressing environmental concerns. As the trend towards eco-friendly solutions grows, we can expect the demand for PP corrugated sheets to rise even further.

Frequently Asked Questions

1. What are PP corrugated sheets made of?

PP corrugated sheets are made from polypropylene, a type of plastic known for its lightweight, durable, and moisture-resistant properties. The sheets are formed through an extrusion process that creates a fluted structure between two flat surfaces.

2. How are corrugated plastic sheets recycled?

Corrugated plastic sheets can be recycled by grinding them into small flakes and reprocessing them into new products. Many manufacturers also produce sheets from recycled materials, contributing to a circular economy.

3. What industries commonly use corrugated plastic sheets?

Corrugated plastic sheets are utilized across various industries, including packaging, signage, agriculture, and construction. Their versatility makes them suitable for both temporary and permanent applications.

4. Can corrugated plastic sheets be customized?

Yes, many manufacturers offer customization options for corrugated plastic sheets. Businesses can order sheets in specific sizes, thicknesses, colors, and even printed designs to suit their unique needs.