rotary table intelligent assembly machine workshop so messy, how to do? The production site of many enterprises is a word: chaos! Managers can't do anything about it, or even get used to it. Why does our product quality or service never improve? Why do we always put off the customer's delivery time? Why are our costs so high? Because our site management is dirty, messy and poor.

Whether an enterprise management is in place, the most intuitive and effective observation is to look at his work site, a good management site must be neat and orderly, so that the quality of enterprise products can be guaranteed, and the cohesion and centripetal force of personnel will be much better than the chaotic enterprise on the scene...

In fact, the site management is numerous, the basic elements are only three: people, things, places; The situation on the scene is ever-changing, and it boils down to only "two streams" : logistics and information flow.

Field managers must make detailed analysis and research on these three elements and two streams to find problems, analyze reasons, and find out the answers to solve problems. To put it simply:

First, check the process flow

2. Do the math on the assembly line

Three, the action elements are reduced

Fourth, the floor plan has been adjusted upward

Five, transport time and space pressure

Six, man-machine efficiency mentioned

7. Shrink key routes

Eight, visual management take a look

9. Find the root of the problem

Then, the management of the chaos of workshop management can be started from the following aspects:

Personnel allocation: Is there sufficient equipment, appropriate management levels and management personnel, all types of production personnel and related personnel (production planners, purchasing, quality control, warehouse management, technicians, plumber, etc.) allocation reasonable?

Work process: Has the work process been developed (production scheduling, procurement process, quality inspection procedures and standards, warehouse management methods, etc., site management methods)? Are the departments working according to the process?

Order scheduling: Is it reasonable for the production planner to arrange the production, and is the production capacity overloaded without corresponding measures?

Quality management: Are there corresponding written quality standards, and are the quality personnel inspection and final inspection thoroughly implemented according to the standards? Are problem areas addressed and improved in a timely manner?

Production Management: Is the flow line design reasonable? Are the job requirements clear? Is the production schedule detailed? Are material procurement and preparation keeping up with production needs? Is there a special person responsible for the warehouse management, and the material account is clear? Temporary problems, can the technical personnel timely and effectively deal with? Is the production site sorted out? Is it dirty and disorderly? Failure to distinguish defective products from good ones, causing confusion?

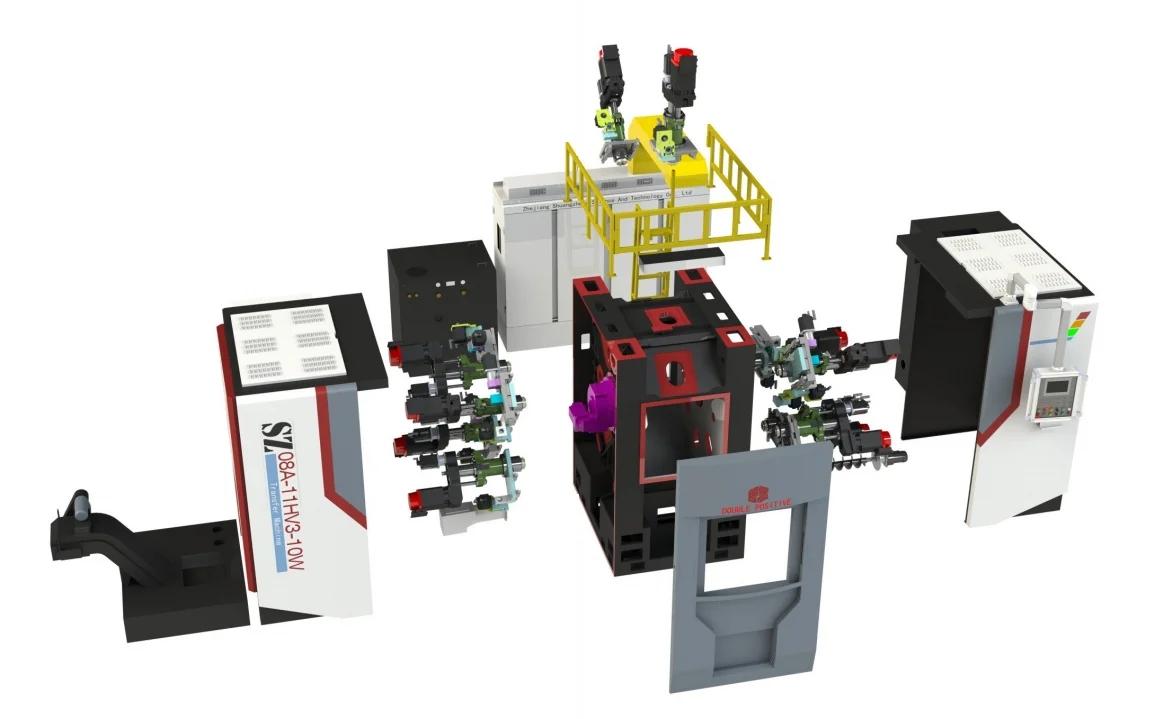

rotary table intelligent assembly machine https://www.zjshuangzheng.com/Rotary-Table-Intelligent-Assembly-Machine.html