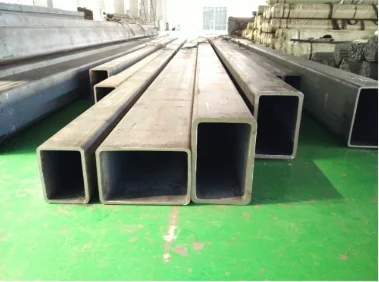

In the world of industrial construction and manufacturing, the materials used play a crucial role in ensuring the strength, durability, and safety of structures and equipment. Among these materials, heavy wall square tubing stands out as a preferred choice for various applications due to its robust properties. This article explores the advantages of heavy wall square tubing, its applications across different industries, and how it contributes to building strong and lasting structures.

Understanding Heavy Wall Square Tubing

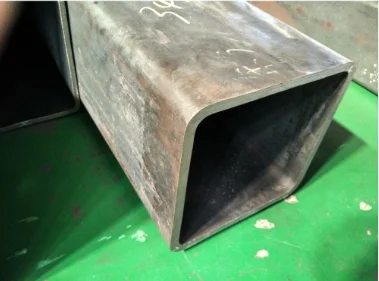

Heavy wall square tubing is a type of structural steel tubing characterized by its square shape and thicker walls compared to standard tubing. This design enhances its strength, making it suitable for applications that require high load-bearing capacity and resistance to deformation. Typically made from carbon steel or alloy steel, heavy wall square tubing is available in various sizes and grades, allowing for versatility in its use.

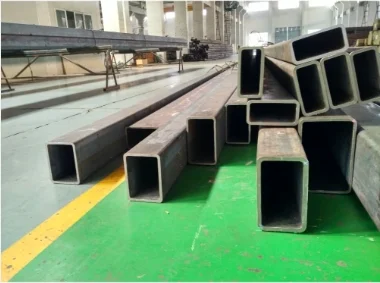

Key Advantages of Heavy Wall Square Tubing

Superior Strength and Rigidity:

One of the primary benefits of heavy wall square tubing is its exceptional strength. The thicker walls provide increased rigidity, allowing the tubing to withstand significant loads without bending or buckling. This makes it an ideal choice for structural applications where safety and stability are paramount.

Enhanced Durability:

Heavy wall square tubing is designed to endure harsh environments and challenging conditions. Its robust construction makes it resistant to wear and tear, corrosion, and impact damage. This durability extends the lifespan of structures and equipment, reducing maintenance costs over time.

Versatility in Applications:

The versatility of heavy wall square tubing allows it to be used in a wide range of applications across various industries. From construction and manufacturing to automotive and agricultural sectors, heavy wall square tubing serves as a fundamental component in many products and structures.

Ease of Fabrication:

Heavy wall square tubing can be easily cut, welded, and formed into various shapes and configurations. This ease of fabrication allows manufacturers to create custom solutions tailored to specific project requirements. The uniform shape of square tubing also facilitates efficient stacking and transportation.

Cost-Effectiveness:

While heavy wall square tubing may have a higher initial cost compared to lighter alternatives, its long-term benefits often outweigh the upfront investment. The combination of durability, reduced maintenance needs, and enhanced performance contributes to overall cost savings throughout the lifecycle of the product.

Applications Across Industries

Heavy wall square tubing finds application in numerous industries due to its strength and durability:

Construction:

In construction projects, heavy wall square tubing is commonly used for structural supports such as columns, beams, and trusses. Its ability to bear heavy loads makes it suitable for both residential and commercial buildings.

Manufacturing:

Heavy wall square tubing is utilized in manufacturing equipment frames, conveyor systems, and material handling systems. Its strength ensures that machinery can operate efficiently without risk of failure.

Automotive:

In the automotive industry, heavy wall square tubing is employed in the production of vehicle frames, chassis components, and suspension systems. Its robustness contributes to vehicle safety and performance.

Agriculture:

Agricultural equipment often relies on heavy wall square tubing for components such as trailers, implements, and machinery frames. The strength of the tubing allows it to withstand the rigors of agricultural use.

Energy Sector:

Heavy wall square tubing is used in the energy sector for constructing support structures for oil rigs, pipelines, and renewable energy installations such as wind turbines. Its durability is essential for withstanding environmental challenges.

Infrastructure:

In infrastructure projects like bridges and towers, heavy wall square tubing provides essential support elements that must endure significant stress while maintaining structural integrity over time.

Furniture Manufacturing:

The furniture industry also benefits from heavy wall square tubing in creating sturdy frames for tables, chairs, shelving units, and other decorative pieces that require both aesthetic appeal and strength.

Safety Equipment:

Heavy wall square tubing is often used in safety equipment such as guardrails, handrails, and protective barriers due to its ability to withstand impacts while providing reliable protection.

Conclusion

Heavy wall square tubing serves as a vital component in various industrial applications due to its strength, durability, versatility, ease of fabrication, and cost-effectiveness. As industries continue to evolve with increasing demands for robust materials that can withstand challenging conditions, heavy wall square tubing remains an essential choice for engineers and manufacturers alike.

With companies like TORICH leading the way in producing high-quality steel pipe materials, businesses can confidently rely on heavy wall square tubing for their structural needs. As we move toward a future defined by innovation and sustainability in construction practices, the role of strong materials like heavy wall square tubing will undoubtedly continue to grow—ensuring safe and durable solutions across all sectors.

The Role of Hydraulic Telescopic Cylinders in Mobile Equipment