When it comes to mechanical systems, the efficiency and durability of the components involved are paramount. One such critical component is the pulley, a fundamental part of transmission systems that helps in the smooth transfer of mechanical power. In this guide, we will compare the Circular Arc Pulley and the Traditional Pulley, exploring their differences, advantages, and applications in various industries.

What is a Circular Arc Pulley?

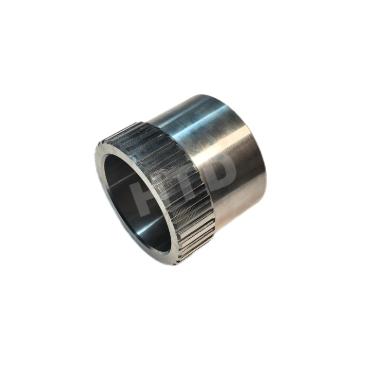

A Circular Arc Pulley is a pulley that is designed with an arc-shaped groove, which helps improve the grip and contact with the belt or rope that runs through it. This specialized design allows the pulley to distribute pressure more evenly, leading to better load management and reduced wear and tear. Circular arc pulleys are particularly known for their ability to increase efficiency in power transmission systems.

What is a Traditional Pulley?

In contrast, a Traditional Pulley typically has a V-shaped groove, which is the standard design for most pulleys. These pulleys are widely used in various industrial and mechanical systems, from simple hand-operated machines to complex machinery. Traditional pulleys are functional, cost-effective, and can handle a wide range of loads.

Key Differences Between Circular Arc Pulleys and Traditional Pulleys

-

Groove Design:

-

Circular Arc Pulley: The groove in a circular arc pulley is shaped like a segment of a circle, which enhances the contact surface area between the belt and pulley.

-

Traditional Pulley: The groove in a traditional pulley is V-shaped, which can lead to higher wear and tear due to concentrated pressure at the point of contact.

Efficiency:

-

Circular Arc Pulley: The even distribution of pressure in a circular arc pulley improves efficiency by reducing friction and heat generation. This means less energy is wasted, making the system more energy-efficient.

-

Traditional Pulley: Traditional pulleys tend to have higher friction due to the point contact between the belt and the pulley, which can reduce overall efficiency.

Durability:

-

Circular Arc Pulley: The design of a circular arc pulley helps in distributing the stress across a larger area, leading to less wear and tear, and extending the lifespan of both the pulley and the belt.

-

Traditional Pulley: Traditional pulleys may experience quicker wear because of the sharper V-shaped groove, which increases localized pressure and friction.

Applications:

-

Circular Arc Pulley: These pulleys are ideal for high-precision applications where efficiency, reduced wear, and longevity are critical. They are often used in industries that require smooth, constant power transmission, such as automotive, robotics, and industrial machinery.

-

Traditional Pulley: Traditional pulleys are still widely used in various mechanical applications where cost-effectiveness is more important than specialized performance. They are common in simple conveyor systems and some machinery.

Cost:

-

Circular Arc Pulley: Due to the precision required in manufacturing and the benefits they offer in performance, circular arc pulleys are typically more expensive than traditional pulleys.

-

Traditional Pulley: Traditional pulleys are often cheaper to produce, making them a more economical option for basic applications.

Why Choose Circular Arc Pulley Over Traditional Pulley?

-

Improved Performance: The smoother operation of circular arc pulleys results in less energy lost to friction, making them ideal for applications where performance is critical.

-

Longer Lifespan: With better load distribution and reduced friction, circular arc pulleys often last longer, which can lead to lower maintenance and replacement costs.

-

Better for Precision Machines: Circular arc pulleys are often used in precision machinery where consistent power transmission is necessary. Their ability to maintain tension and alignment across various parts of the system helps ensure reliability and smooth operation.

Suzhou Hetuoda Machinery Manufacturing Co., Ltd. – Your Trusted Supplier of High-Precision Pulleys

At Suzhou Hetuoda Machinery Manufacturing Co., Ltd., we specialize in providing high-precision transmission parts, including circular arc pulleys, traditional pulleys, timing belt pulleys, tooth plates, tightening wheels (sleeves), gears, and various other machined parts. Our factory, covering an area of over 4000 square meters, employs a team of 85 professionals, including 12 skilled technicians and 8 dedicated quality control staff.

We pride ourselves on our ability to deliver high-quality, durable, and efficient pulleys that meet the diverse needs of our clients. With years of expertise in manufacturing, we also offer OEM services, allowing us to customize products to meet the specific requirements of your applications.

Conclusion

When deciding between a Circular Arc Pulley and a Traditional Pulley, it's essential to consider the specific needs of your system. While traditional pulleys may be suitable for general applications, circular arc pulleys offer distinct advantages in terms of efficiency, durability, and performance. At Suzhou Hetuoda Machinery Manufacturing Co., Ltd., we ensure that you receive the best products tailored to your needs, helping you achieve optimal system performance.

Feel free to contact us for more information or to place an order. We are committed to providing high-quality pulleys and transmission parts that can improve the efficiency and reliability of your machinery.