Overview:

5052 aluminum sheet is a popular alloy in the 5000 series, known for its excellent corrosion resistance, particularly in marine environments. It is one of the most commonly used non-heat-treatable aluminum alloys, offering a good balance of strength, formability, and weldability.

Chemical Composition:

The primary alloying elements in 5052 aluminum are:

-

Magnesium (Mg): 2.2-2.8%

-

Chromium (Cr): 0.15-0.35%

-

Iron (Fe): ≤ 0.40%

-

Silicon (Si): ≤ 0.25%

-

Copper (Cu): ≤ 0.10%

-

Manganese (Mn): ≤ 0.10%

-

Zinc (Zn): ≤ 0.10%

-

Aluminum (Al): Balance

Properties:

-

Corrosion Resistance:

-

Excellent resistance to corrosion, especially in marine and saltwater environments.

-

Resistant to industrial chemicals and atmospheric conditions.

-

-

Strength:

-

Moderate strength, higher than 3003 aluminum.

-

Not heat-treatable, but can be work-hardened to increase strength.

-

-

Formability:

-

Good formability, making it suitable for various fabrication processes.

-

Can be easily bent, shaped, and formed without cracking.

-

-

Weldability:

-

Excellent weldability using conventional welding methods.

-

Suitable for both gas and arc welding.

-

-

Machinability:

-

Fair machinability, but not as good as 2000 or 6000 series alloys.

-

Requires proper tools and techniques for effective machining.

-

-

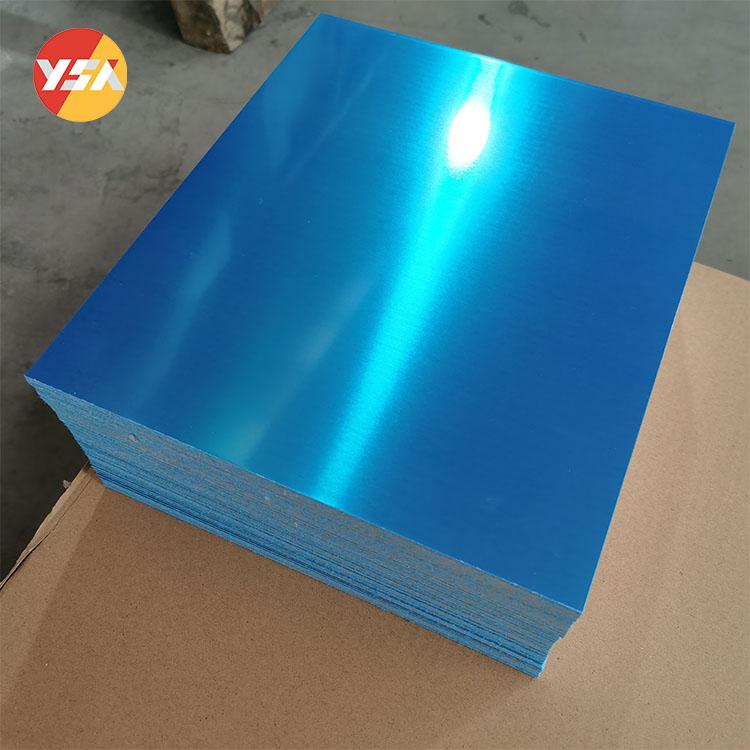

Surface Finish:

-

Can be easily anodized or painted for enhanced appearance and additional protection.

-

Applications:

5052 aluminum sheets are widely used in various industries due to their versatile properties. Common applications include:

-

Marine: Boat hulls, gangways, and other marine components.

-

Automotive: Fuel tanks, panels, and other structural parts.

-

Construction: Roofing, wall panels, and architectural elements.

-

Electronics: Chassis, enclosures, and other components.

-

General Fabrication: Tanks, pressure vessels, and other fabricated parts.

Available Tempers:

5052 aluminum sheets are available in different tempers to suit various applications:

-

H32: Strain-hardened and stabilized, offering a good balance of strength and formability.

-

H34: Further strain-hardened for higher strength.

-

H36: Even higher strength, suitable for more demanding applications.

-

H38: Maximum strength achievable through strain-hardening.

Advantages:

-

High corrosion resistance.

-

Good strength-to-weight ratio.

-

Excellent formability and weldability.

-

Suitable for marine and industrial environments.

Disadvantages:

-

Lower strength compared to heat-treatable alloys like 6061.

-

Limited machinability compared to other aluminum alloys.

Conclusion:

5052 aluminum sheet is a versatile and reliable material choice for applications requiring good corrosion resistance, moderate strength, and excellent formability. Its wide range of applications and availability in various tempers make it a popular choice in many industries.