At present, the precision requirements of special type milling machine are no longer limited to the requirements of static geometric accuracy, and its motion accuracy, thermal deformation, vibration monitoring and compensation have received more and more attention. Hard rail CNC lathe is a kind of machine tool with high precision and high efficiency. Equipped with multi-station tower or power tower, the processing process performance is wide, can be processed straight line, oblique cylinder, arc and a variety of complex workpieces. So what are the working conditions of this lathe? There are four main points:

1, temperature: suitable temperature.

2, the machining center instruction manual stipulates: the user can not change the parameters set in the control system when using the machining center. The setting of these machining center parameters is directly related to the dynamic characteristics of each part of the machining center. Adjust the gap compensation parameters only according to the actual situation.

3, the processing center location of the environmental requirements: the processing center should be far from the source, to avoid direct sunlight, to avoid thermal radiation, to avoid the impact of moisture and airflow. If there is a vibration source near the CNC machining center, anti-vibration trenches should be set up around the machining center. Otherwise, it will affect the machining accuracy and stability of the CNC machining center, so that the electronic components have poor contact, failure occurs, and the reliability of the machining center is affected.

4, power requirements: the general processing center is installed in the machining workshop, not only the ambient temperature changes, the use of poor conditions, and a wide variety of mechanical and electrical equipment, resulting in large fluctuations in the power grid. Therefore, when installing the machining center, the power supply voltage must be strictly controlled. Power supply voltage fluctuations must be controlled within the allowable range and kept relatively stable. Otherwise, it will affect the normal work of the CNC system.

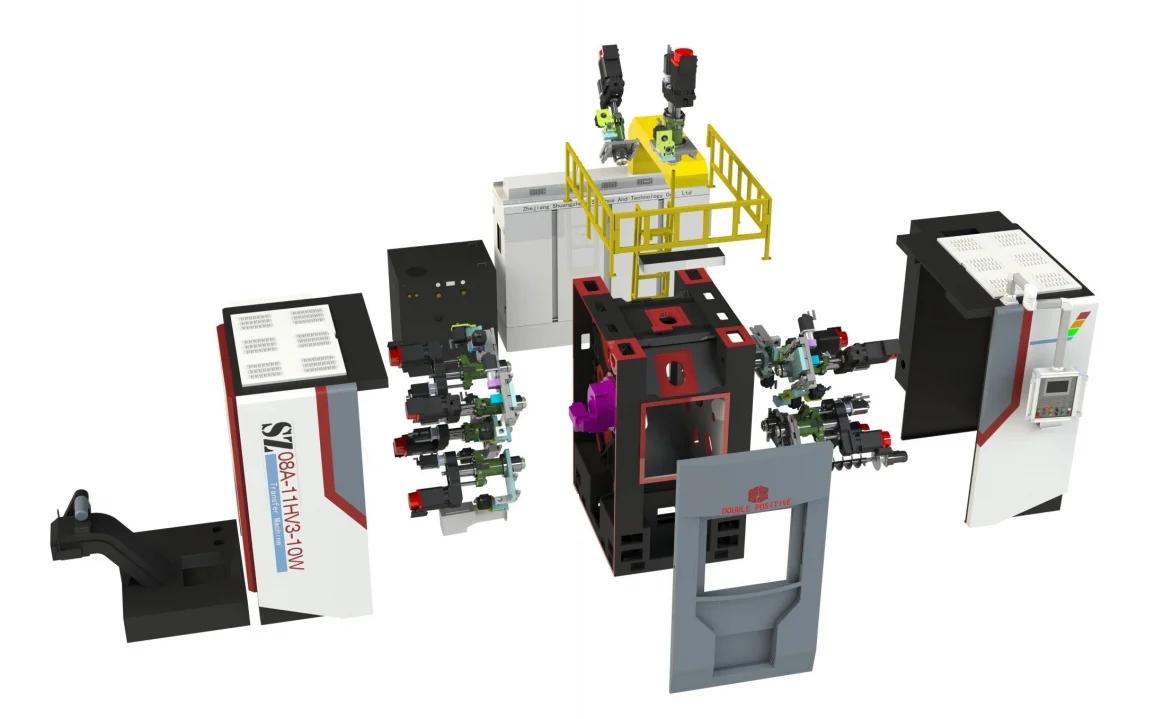

The progress and development of special type milling machine technology has created favorable conditions for the development of modern manufacturing industry, and promoted the manufacturing industry to develop in the direction of high efficiency, high quality and humanization.

special type milling machine https://www.zjshuangzheng.com/Special-Machine-for-Servo-Gate-Valve-SZ02N-125-160-CNC.html