As personal technology becomes more compact, portable, and lifestyle-integrated, the materials used in electronic device construction must also evolve. Among the innovations shaping this new era is TPU Compound Film , a lightweight yet highly durable solution that meets the dual demands of functionality and aesthetic flexibility in consumer electronics and smart accessories.

More than just a protective layer, TPU Compound Film provides essential properties—impact resistance, tactile comfort, transparency, and chemical stability—that are critical in devices such as smartwatches, earbuds, power banks, wearable chargers, and phone cases. Its application supports both user experience and product longevity, particularly in environments where durability and daily handling are key.

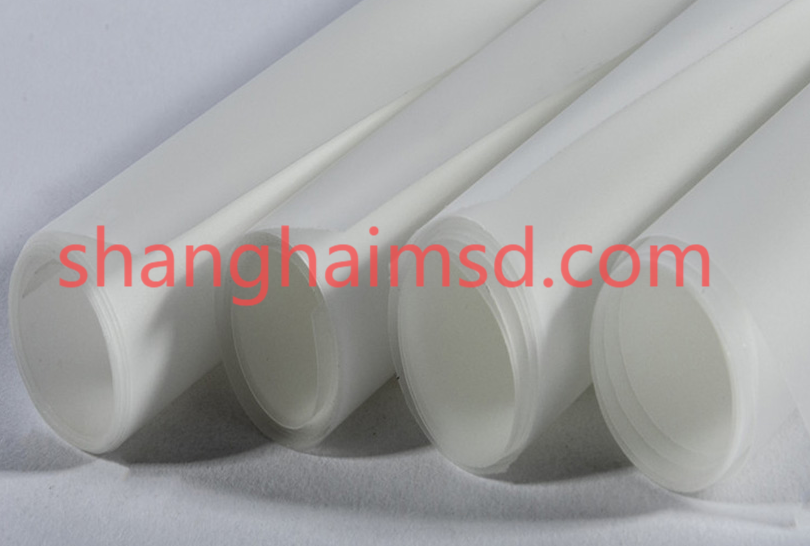

Shanghai MSD International Trade Co. provides advanced TPU films tailored for the electronics industry, offering surface finishes that range from high-gloss clarity to anti-fingerprint matte. Their film products are engineered to withstand heat exposure, UV degradation, and repeated bending without cracking or yellowing—features especially important in flexible device enclosures, wristbands, or cable covers.

What makes TPU film stand out is its ability to bond easily with substrates like polycarbonate, ABS, or fabric. Through lamination or insert molding, the film adheres cleanly to curved or contoured surfaces, allowing for seamless design transitions without interfering with device functionality. This is particularly valuable in the production of minimalist, no-seam designs—where every millimeter counts, and edges must stay flush and smooth.

In addition to structural integrity, TPU compound film contributes to the overall user experience. Its soft-touch finish adds grip and comfort, especially in handheld or wearable products. For example, fitness bands and headphones benefit from non-slip surfaces that remain skin-friendly even during intense use. The hypoallergenic nature of the film also makes it suitable for direct skin contact, an essential factor in wellness or medical-grade wearables.

The film’s flexibility enables creative form factors, such as folding devices, stretchable electronics, or embedded lighting systems. Its transparency allows for backlit displays, logo illumination, or sensor exposure without compromising protection. Shanghai MSD offers printable versions that support digital graphics or QR integration, adding branding opportunities without the need for extra adhesives or printed labels.

TPU compound film also plays a role in extending device lifecycles. Its scratch-resistant coating preserves clarity and smoothness even under daily friction—helping products retain their value and reducing customer dissatisfaction. This durability makes it a material of choice for brands focused on reliability and visual appeal in competitive electronics markets.

Beyond performance, the material aligns with modern sustainability goals. Compared to legacy plastic coatings, TPU is recyclable, and Shanghai MSD uses solvent-free manufacturing methods to minimize emissions and environmental impact. For brands that emphasize green design, the use of clean, safe, and modular materials like TPU sends a strong message to conscious consumers.

As consumer electronics continue to evolve toward wearability, customizability, and sustainability, the need for versatile surface solutions grows. TPU compound film answers this need by combining mechanical strength, aesthetic versatility, and responsible sourcing—all within a thin, flexible format that suits next-generation tech.For electronics designers, OEM developers, and product engineers exploring tailored material solutions, visit: https://www.shanghaimsd.com/news/growing-industrial-use-of-tpu-compound-film-highlights-material-s-versatility.html .