In the world that requires a civil engineer and infrastructure, the life and integrity of solid structures are crucial. From drainage systems and drainage pipelines to tunnels and storage tanks, this important property is constantly exposed to corrosive elements, abduction currents and aggressive chemicals. Traditional protective coatings often decrease, for wear, chemical attacks and microbial falls over time. This is the place where the HDPE T-RB lining sheet appears as a unique solution, and offers a strong, long-lasting and very effective barrier to deterioration.

The Genesis of Enduring Protection

The concept behind HDPE R-rib liner sheets is simple, yet simple: making a mechanical anchor, impenetrable layer that protects concrete from the rigid environment. Unlike the applied coatings, which perfectly depend on adhesion and can delimately, T-rib lines are integrated into a physically concrete structure during the casting. This mechanical ratio, obtained through specific T-shaped ribs, ensures a permanent and inseparable compound, eliminates practically the risk of contingent or blisters. It is a fundamental difference that HDPE over traditional methods lifts the T-ribs sheet, and establishes them as Go-to as for important infrastructure projects that seek final stability.

Unpacking the Material Marvel: HDPE

The root of these malignant lines has high density polyethylene. HDPE is just no plastic; It is a thermoplastic polymer observed for its extraordinary chemical resistance, high strength-tightness ratio and remarkable imperfection. It is largely affected by a wide range of acid, alkaline, salts and organic solvents, which is ideal for the atmosphere where chemical attacks are a significant concern. In addition, HDPE shows excellent resistance to friction, an important feature of applications associated with abrasive grinding or high-road flow. The inherent flexibility allows it to match different forms and shapes, while its resistance to UV radiation ensures long -term performance even when exposed to sunlight. These properties make collective HDPE the right material to make HDPE a durable and reliable protective barrier.

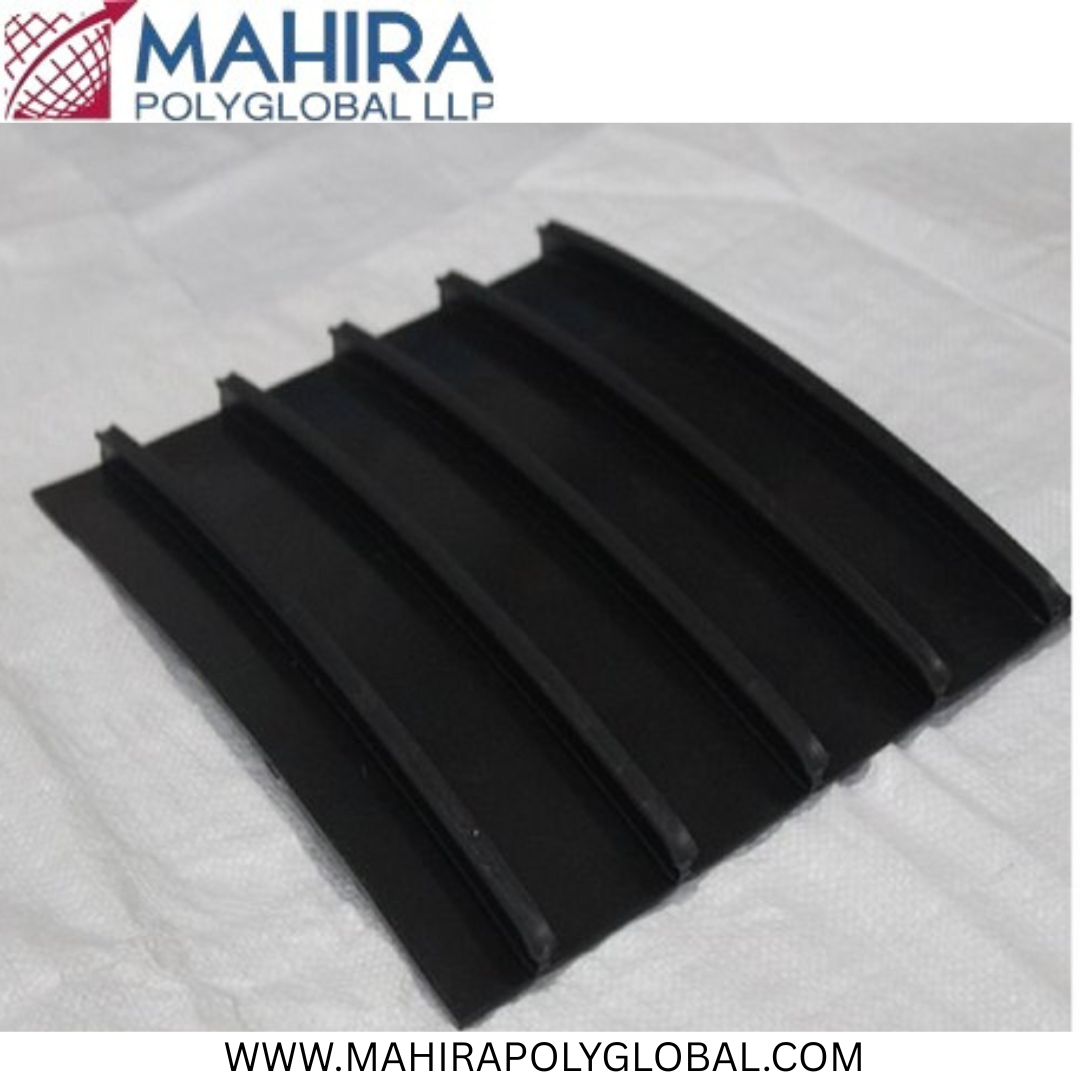

The Ingenious Design of T-Ribs

The unique "T -rib" profile is a defined feature of these lining sheets. These ribs are designed to be built directly in wet concrete during insertion, scattered from the main sheet, spread vertically from the main sheet. When the concrete is cured and hard, it improves these ribs, forming a mechanical interlock that is almost impossible to break. This simple design provides many great benefits. First, it ensures a uniform and continuous bond, which prevents the entry of corrosive substances between lining and concrete. Second, it distributes some stress evenly, reduces the ability to crack or delay. Finally, T-ribs act as an anchor, and also hold the feed well during hydrostatic pressure or aggressive flow. This mechanical meeting separates MAHIRA POLYGLOBAL LLP casing from the surface from the surface, which guarantees a protective layer that is actually integrated with the structure.

Applications Across Industries

The versatility of HDPE T-rib lining is clear in their wider application in different industries. In wastewater treatment, they are indispensable for pinester, clarifying and pumping stations, which protect concrete from the corrosive effects of hydrogen sulfide and other invasive chemicals found in sewage. For municipal drainage systems, HDPE R-R-rib lining, a close cousin with a similar anchoring mechanism, is used, but sometimes different RIB profiles, are used for rehabilitation of large-scale aging concrete pipes and manhole, and expand their lifetime for decades. In tunnel construction, this lining provides a strong defense against entrance and chemical attack. Storage tanks for different fluids, including industrial chemicals and drinking water, are also strongly advantageous of impensable and chemically resistant properties of these lines. The selection of applications is a will for the adaptability of the lining and better performance in the diverse, challenging environment. When considering the best protective solution, sensible engineers often look for a recognized HDPPRIB liner manufacturer known for quality and reliability.

Installation: A Seamless Integration

The installation process for HDPE T-RB lining is designed for efficiency and efficiency. The sheets are usually prepared for specific dimensions and then distributed in the shape work before inserting concrete. T-ribs face the inner side of the shape, so that fresh concrete can flow around and surround them. Specific welding techniques, often involving extrusion welding or welding of hot road, are used to create a continuous, leak -proof stitch between adjacent sheets and get in around, secure a monolithic barrier. This carefully installation, combined with the underlying properties of HDPE, results in a lining system that is not only durable, but also virtually impervious. The expertise of the HDPE t rib liner manufacturer is often spread to provide guidance and help with optimal installation practices.

The Long-Term Economic Advantage

While the original cost of HDPE T-rib lining may be slightly higher than any traditional occupancy, their long-term economic benefits are undisputed. Resistance to their extraordinary durability and decline reduces maintenance requirements and extends the life of solid structures for decades. Adequate savings, rehabilitation and replacement costs are translated into adequate savings during the property stand. In addition, the increased safety leaks given by these lines reduce the risk of environmental pollution, avoiding potential legal obligations and cleaning expenses. Investing in HDPE T-rib lining sheets is therefore a strategic decision that provides a better return on investment through unique life and low life cycle.

Conclusion

HDPE T-RB Lining sheets represents a paradigm change in solid security. Their unique design combined with the underlying properties of HDPE t rib liner creates a durable, chemically resistant and impenetrable obstacle that is mechanically integrated with concrete structure. From reducing rust in the infrastructure of wastewater, to protect tunnels and storage tanks, these linings provide unique long life and reduce life cycle costs. As the demand for strong and durable infrastructure increases, the HDPE T-rib linings stand out as a proven, reliable and inevitable solution, such as to ensure long-term integrity and performance of important concrete values. When considering such important security, it is important to look for a reliable HDPPRIB liner manufacturer for the highest quality and performance guarantee.

Frequently Asked Questions

Question: How is HDPE T-RB Lining sheets different from traditional protective coatings for concrete?

A: On the other hand, the HDPE t-rib lining plate eases the T-shaped ribs, which mechanically insert into wet concrete, creating a permanent, inseparable bond.

Question: What are the biggest benefits of using HDPE as a material for T-rib lining?

A: Polyethylene with high density (HDPE) provides extraordinary chemical resistance, making it impenetrable for a wide range of acid, alkaline, salts and organic solvents usually found in the industrial and sewer environment. It also shows excellent frictional resistance, high strength-tightness conditions and impregnability.

Question: Can HDPE T-RB Lining sheets be used for rehabilitation of existing concrete structures, or are they just for new buildings?

A: While HDPE T-RB lining sheets is mainly designed for new concrete structure, where they are inserted into wet concrete, variations such as HDPE R-R-RB liability can be adapted to rehabilitate existing concrete structures. In such cases, lines can be installed in the existing structure, often to create a new, preserved surface, with a grout.

Question: Who is the largest manufacturer of HDPE T-Rib Liner Sheets?

A: However, Mahira Polyglobal LLP is a prominent manufacturer and exporter of HDPE T-Rib Liner Sheets, known for their quality products and presence in the market. They emphasize their focus on quality and customer satisfaction in manufacturing these sheets, which are vital for corrosion protection in various concrete applications like sewage pipes and tunnels.