In the area of modern construction and development of infrastructure, the discovery of materials that offer extraordinary durability, resistance and lifetime is constant. Between the countless available solutions, the HDPE T-rib lining sheet has emerged as a foundation stone for protecting concrete and other structural elements from the aggressive environment. These special sheets, characterized by their unique T-shaped ribs, are more than just a barrier; They are a sophisticated engineering solution designed to expand the life of important property. Increasing demand for strong and durable infrastructure has inspired the HDPE T-RB liner sheet in advance of material selection for different types of applications, from wastewater treatment plants to tunnels and industrial control structures.

The Genesis of Durability: Understanding HDPE

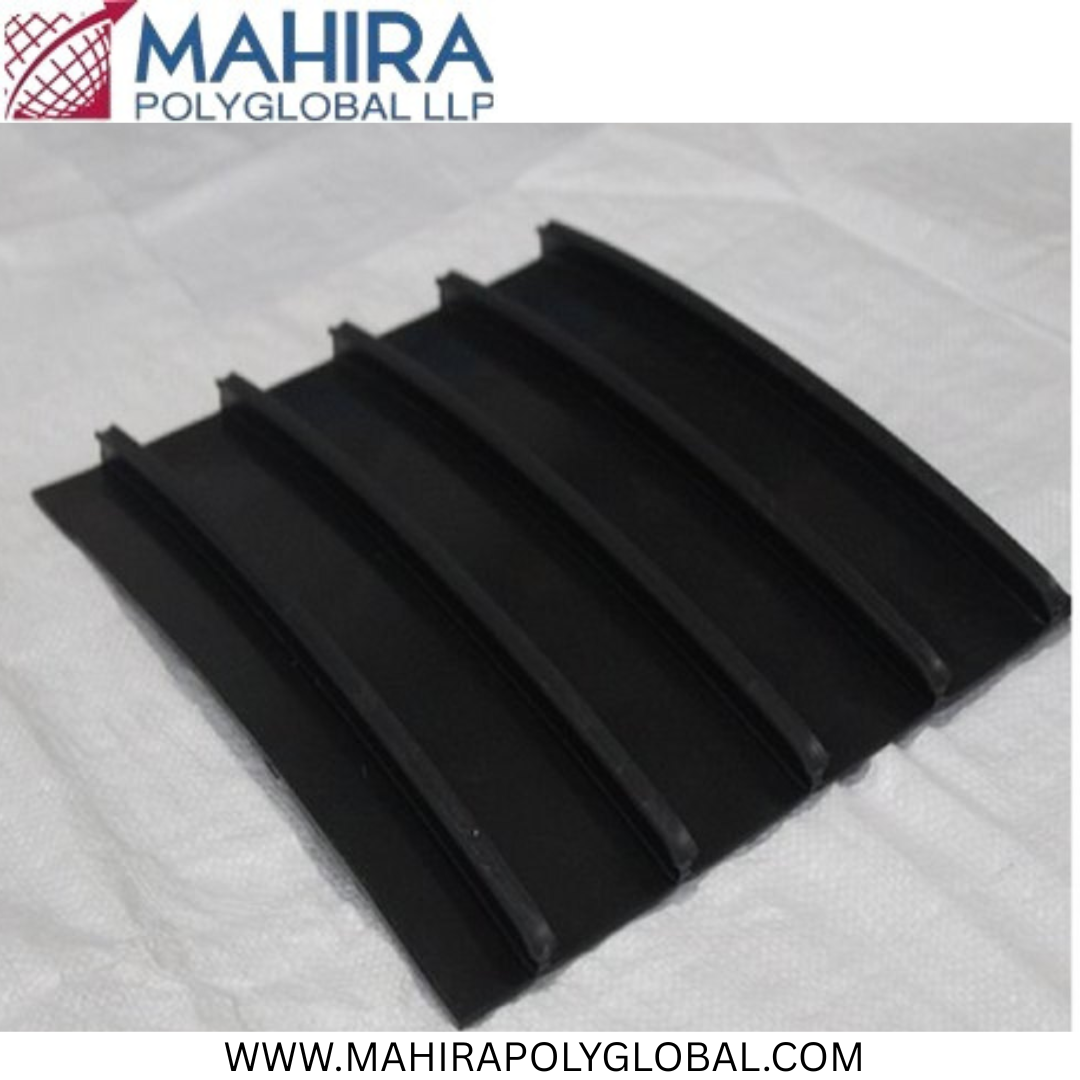

HDPE T-rib feeding sheets has high density polyethylene. Unlike many other plastics, HDPE claims a high -order molecular structure, which is translated into better stiffness and indispensity. These inherent properties make HDPE R-rib liner sheets an ideal candidate for applications seeking long -term performance under tough conditions. When the T-rib is cast into the sheet, these properties are further improved by the mechanical interlock mechanism provided by the ribs, which form almost an inseparable binding with concrete. This fusion of material science and intelligent design ends in a feed system that provides wide and long -lasting protection.

The Distinctive Advantage of T-Rib Design

These ribs are not just aesthetics; They serve an important engineering ceremony. During the process of inserting concrete, the wet concrete flows around and meets these ribs, providing a strong mechanical anchor. This interlock mechanism ensures that the lining is safely attached to the concrete structure, which prevents itself delay, during critical hydrostatic pressure or seismic activity. This mechanical bonding is much better than traditional glue -based lining systems, which may be exposed to slimmer failure over time due to chemical falls, temperature fluctuations or insufficient surface preparation. The T-rib design mainly makes the lining an integral part of the fixed structure, expanding the general integrity and resistance to the decline in different forms.

Applications Across Diverse Industries

The versatility of the HDPE t rib liner manufacturer allows their application in a wide range of industries, each of which benefits from its unique protective properties. In wastewater treatment properties, where concrete structures are exposed to persistent corrosive chemicals, microbial attacks and abrasive currents, the HDPE T-ribs provide an impenetrable barrier. It extends clarity, digestion and life for channels significantly, reduces the costs of maintenance and operating disorder. For tuning projects, whether for transport or tools condensed, this lining provides significant protection against groundwater infiltration, aggressive soil and root infiltration, and protects the structural integrity of the tunnel drilling. Industrial control structures, as used for chemical storage or processing, are more dependent on these lines to prevent leakage and protect the underlying concrete from extremely corrosive substances. In addition, they are used for fast mining operations, power plants and even different control and safety requirements in the agricultural sector, which shows the widespread appeal and efficiency of HDPE T-rib lining.

Installation and Longevity: A Synergistic Process

The successful installation of MAHIRA POLYGLOBAL LLP is important to feel their complete protective ability. Usually, sheets are pre -produced to fit specific dimensions and shapes of the structure. They are then deployed in the form work before adding concrete. The concrete is then inserted, and ensures carefully that it meets T-ribs fully, eliminates zero air and creates a complete bond. This spontaneous integration, combined with the inherent durability of HDPE, ensures extraordinary long life, often more than the design life of primary concrete structure. Maintenance requirements have been significantly reduced, and expensive repair of concrete or premature compensation requirements is largely eliminated. This long-term performance makes HDPE T-rib liner a very reasonable alternative in the long term despite the early content costs.

Considering an HDPE T-Rib Liner Manufacturer

A well-known manufacturer will not only deliver high quality HDPE T-rib lining, but will also provide extensive technical assistance including design help, installation guidelines and quality assurance documentation. They can understand the nuances of different applications and loose tailoring to meet specific project requirements. In addition, a reliable HDPE R-RB lining sheet will follow strict quality control measures in the supplier production process, and ensure the stability and performance of their products. Taking connection to experienced professionals in this field is guaranteed that distributed products meet the highest standards of durability and reliability, and provide security for engineers and project managers. The selection process should prefer a proven tracking list of experience, reputation and successful project delivery.

Conclusion

From corrosive chemical chemicals to abrasive currents and hydrostatic pressure, these linings provide a long -lasting and cost -effective solution to increase the life of significant infrastructure. Since the world prioritizes durable and flexible construction practices, the role of HDPE t rib liner will expand, and strengthen its position as an indispensable material for sustainable security.

Frequently Asked Questions

Question: What is the primary benefit of using HDPE T-RB Lining sheets on other concrete lining methods?

A: The primary benefit lies in the unique mechanical interconnection mechanism provided by T-rib. It creates a better, inseparable binding with concrete, even under a general failure point for glue -based or other low integrated lining systems, under significant pressure or environmental tension, prevents philanthropism.

Question: Can T-rib lining be used drinking water?

A: Yes, many HDPE T-RB Lining sheets are produced by Virgin HDPE harpixes, which meet drinking water standards, such as NSF/ANSI 61. It is important to confirm specific certificates and approval with HDPE T-RB lining to ensure compliance with local regulations for paw.

Question: What factors should be considered when choosing HDPE T-rib lining for a specific project?

A: Important factors to be considered include the type and concentration of chemicals, which will be exposed to lining, expected temperature range, wear and tear on wear, essential life and distinctive installation method. Consulting with an experienced HDPE T-rib lining manufacturer or supplier can help choose the optimal product for the unique requirements for your project.

Question: Who is the largest manufacturer of HDPE T-Rib Liner Sheets?

A: While pinpointing a single "largest" global manufacturer of HDPE T-Rib Liner Sheets can be challenging due to varying production metrics and regional focuses, Mahira Polyglobal LLP positions itself as a prominent and highly regarded manufacturer and exporter in this specialized field. They are known for their high-quality HDPE T-Rib Liner Sheets, which are widely used for corrosion protection in concrete structures like sewage pipes, chemical tanks, and tunnels.