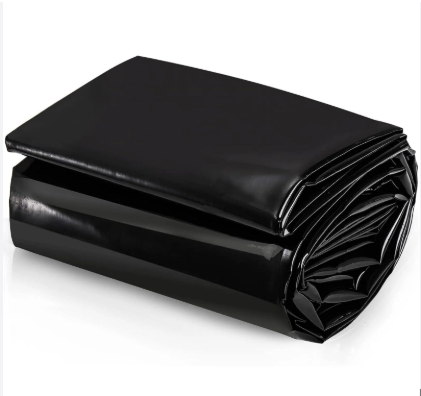

In this day and age of water conservation and sustainable agriculture, the importance of durable, high-performance pond lining materials cannot be overstated. One that has transformed the containment industry is the HDPE Pond Liner. HDPE, (or High-Density Polyethylene) is a durable and chemically resistant polymer that presents the perfect type of lining options when it comes to lining ponds, reservoirs, canals and water containment systems. One reason that the HDPE geomembrane pond liner is a good choice for industrial and agricultural application is because of its excellent mechanical and chemical properties.

Superior Technical Attributes of HDPE Pond Liners

HDPE pond liners stand out from traditional liners due to their specifications which are not in the same range. Typically made in thickness range of 0.5 mm to 2.5 mm, HDPE pond liners are meant to withstand the worst environments. According to the HDPE pond liner specifications , they offer high tensile strength, excellent elongation, low permeability and great resistance to chemicals. The fact that these liners can be roll-fusion welded means that you will not only have no leaks between joints, but it will also have the minimum environmental impact. All of these technical properties make HDPE pond liners an exceptional.

Applications Across Industries

The HDPE pond liner is not limited to a single industry. Its versatility is limitless. Farmers use HDPE pond liners for irrigation ponds, water harvesting tanks, and fish farming bodies of water. Industry utilizes HDPE pond liners to line evaporation ponds, hazardous waste landfills, and tailing ponds from mining. Environmental engineering projects utilize a geomembrane liner as an HDPE pond liner to protect the soil from toxic substances contaminated by water and prevent the seepage of contaminants into the ground below. The cross-industry use of HDPE pond liners is driven by impermeability and chemical resistance.

Cost Efficiency and Market Price Trends

The HDPE pond liner price in India , will vary depending upon thickness, roll size, brand, customization, and demand. Typically the price will range from ₹70 and ₹180 per square meter based upon the liner specifications. The first costs may be slightly high compared to others but when you consider the long-term costs in terms of water retention, low maintenance and long service life, it is relatively inexpensive. The action of HDPE liner use has grown tremendously in the market due to an increase in modern farming and environmental awareness along with this greater demand, Indian manufacturers have maintained low prices on the product.

Installation and Maintenance Considerations

Installing an HDPE pond liner requires appropriate preparations and technical skills to ensure the final product works successfully. A suitable area needs to be flattened and cleared of objects that can be sharp enough to puncture the liner. After installing the liner, the HDPE is unrolled into the contours of the pond area and then is "seamed" together using special either hot air welding machines or wedge welding machines. Seam welding of HDPE pond liner price in india because it creates high shear strength, leak-tight welds at the seams.

Environmental and Agricultural Benefits

The environmental benefits of HDPE pond liners cannot be ignored and are one of these products strong points. These liners allow for no seepage or water waste and promote conservation of water and sustainable agriculture. With water being so scarce in many arid and semi-arid areas of India where groundwater is insufficient, installing an HDPE geomembrane pond liner today will help in retaining and storing water for prolonged periods. Clearly, while water conservation and the preservation of chemicals or pollutants from leaching into soil or groundwater systems are important environmental benefits, HDPE pond liners also provide value for aquaculture by providing a clean and controlled environment.

Market Growth and Demand in India

India's commitment to sustainable agriculture and efficient management of water resources has allowed for development of the HDPE pond liner market. The implementation of government schemes for water conservation, aquaculture, and irrigation infrastructure support has added to demand. There are numerous manufacturers and suppliers who provide a wide variety of value added, tailored solutions that meet many different HDPE pond liner specifications and needs. This has and cost effective HDPE pond liners. With climate change making rainfall more unpredictable, and with farmers, industrialists and environmental engineers finding HDPE liners a long-term water management solution, demand is expected to continue.

Conclusion: A Reliable Investment for a Greener Future

Pond liners made from HDPE are not only about holding water; they represent a step towards a sustainable future at the same time as bringing mechanical strength, chemical resistance, UV stability, and long life as the most recognized and reliable water management system to the industry today. With HDPE geomembrane pond liner , manufacturing improvements, and competitive hdpe pond liner price in India, it is clear that HDPE pond liners will continue to be the most dominant geomembranes for years to come. For agricultural use, aquaculture, industrial containment, and environmental protection, HDPE pond liners are proving to be value for money, and providing consistent reliability. In the case of agricultural applications , aquaculture applications , industrial waste containment applications , or for purposes of environmental protection, HDPE pond liners are proving .

Frequently Asked Questions (FAQs)

Q1: Who is the largest manufacturer of HDPE Pond Liner ?

Singhal Industries Pvt. Ltd. is India's largest HDPE Pond Liner manufacturer. The company is based in Gujarat, and has established a significant position in the geosynthetics and polymer-based products sector.

Q2: How does the HDPE pond liner specifications influence it's performance?

Certain specifications, such as thickness, tensile strength, elongation, and chemical resistance, directly relate to a liner's longevity and effectiveness. Thickers liners can be more puncture resistant, and are better suited for harsh environments, or heavy-duty industrial applications.

Q3: What are the factors that influence the HDPE pond liner price in India?

The major factors contributing to cost include thickness, area covered, brand, installation process, and whether the liner has UV and/or chemical stabilizers included. Generally, customized liners with unique qualities will usually cost more than standard rolls.